INSTALLATION

A-13 A-13

POWER WAVE 355M/405M

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

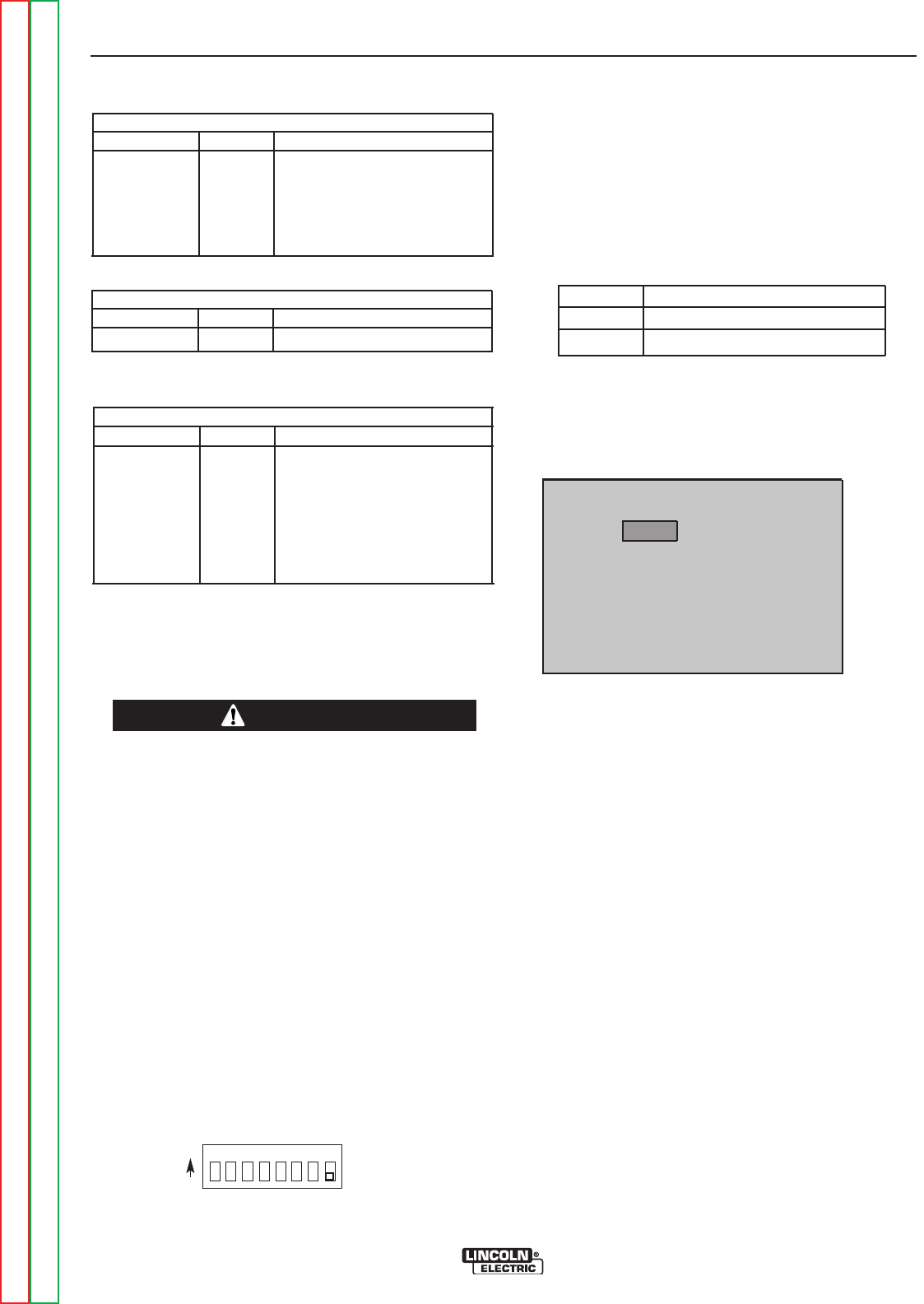

I / O RECEPTACLE SPECIFICATIONS

TABLE A.2

WIRE FEEDER RECEPTACLE

PIN LEAD# FUNCTION

A 53 Communication Bus L

B 54 Communication Bus H

C 67A Electrode Voltage Sense

D 52 +40vdc

E 51 0vdc

TABLE A.3

VOLTAGE SENSE RECEPTACLE

PIN LEAD# FUNCTION

3 21A Work Voltage Sense

TABLE A.4

RS232 RECEPTACLE

PIN LEAD# FUNCTION

2 253 RS232 Receive

3 254 RS232 Transmit

4#Pin5

5#Pin4

6 # # Pin20

20 # # Pin6

7 251 RS232 Common

DIP SWITCH SETTINGS AND

LOCATIONS

DIP switches on the P.C. Boards allow for custom con-

figuration of the Power Wave. To access the DIP switch-

es:

1. Turn off power to the power source at the dis-

connect switch.

------------------------------------------------------------------------

2. Remove the wrap around cover from the power

source.

3. The control board is on the center assembly facing

the case front. Locate the 8-position DIP switch and

look for switch 8 of the DIP switch.

4. Using a pencil or other small object, slide the switch

to the OFF position if the work sense lead is NOT

connected. Conversely, slide the switch to the ON

position if the work sense lead is present.

5. Replace the wrap around and screws. The PC board

will “read” the switch at power up, and configure the

work voltage sense lead appropriately.

O

N

12345678

WARNING

CONTROL BOARD DIP SWITCH:

switch 1 = reserved for future use

switch 2 = reserved for future use

switch 3 = reserved for future use

switch 4 = reserved for future use

switch 5 = reserved for future use

switch 6 = reserved for future use

switch 7 = reserved for future use

switch 8* = work sense lead

switch 8*

work sense lead

off work sense lead not connected

on work sense lead connected

*Factory setting for Switch 8 is OFF.

CONTROL BOARD (DIP Switch Location)

FIGURE A.7

NOTE: For PF10M Dual Boom Feeder set/up and op -

eration. The Power Wave 355M/405M control

board dip switches must be set with 3, 4, 7 to

the “ON” position (Power Wave 355M/405M

input on/off switch must be cycled to enable

any change of dip switches).