– 19 –

OPERATING INSTRUCTIONS

Safety Precautions

Duty Cycle

The Synergic 7F models are rated at 60% duty cycle

* for a maximum current of 600 amps.

* Based on a 10 minute time period (6 minutes on, and 4 minutes off).

KEYPAD SETUP AND OPERATION

Power-Down Save

Power to the Synergic 7F is supplied and controlled

from the power source. The Synergic 7F

automatically senses the loss of power when the

power source is turned off.

Procedure settings, including mode, crater speed,

cold feed speed , run-in speed, weld speed, timers

and acceleration are automatically saved when power

is removed. Arc Voltage setting is retained by the

synergic power source. This feature does not require

batteries and when power is restored it will

automatically return all settings to the state they were

in when power was removed. The power source may

automatically overwrite any or all of these settings

following power-up recall.

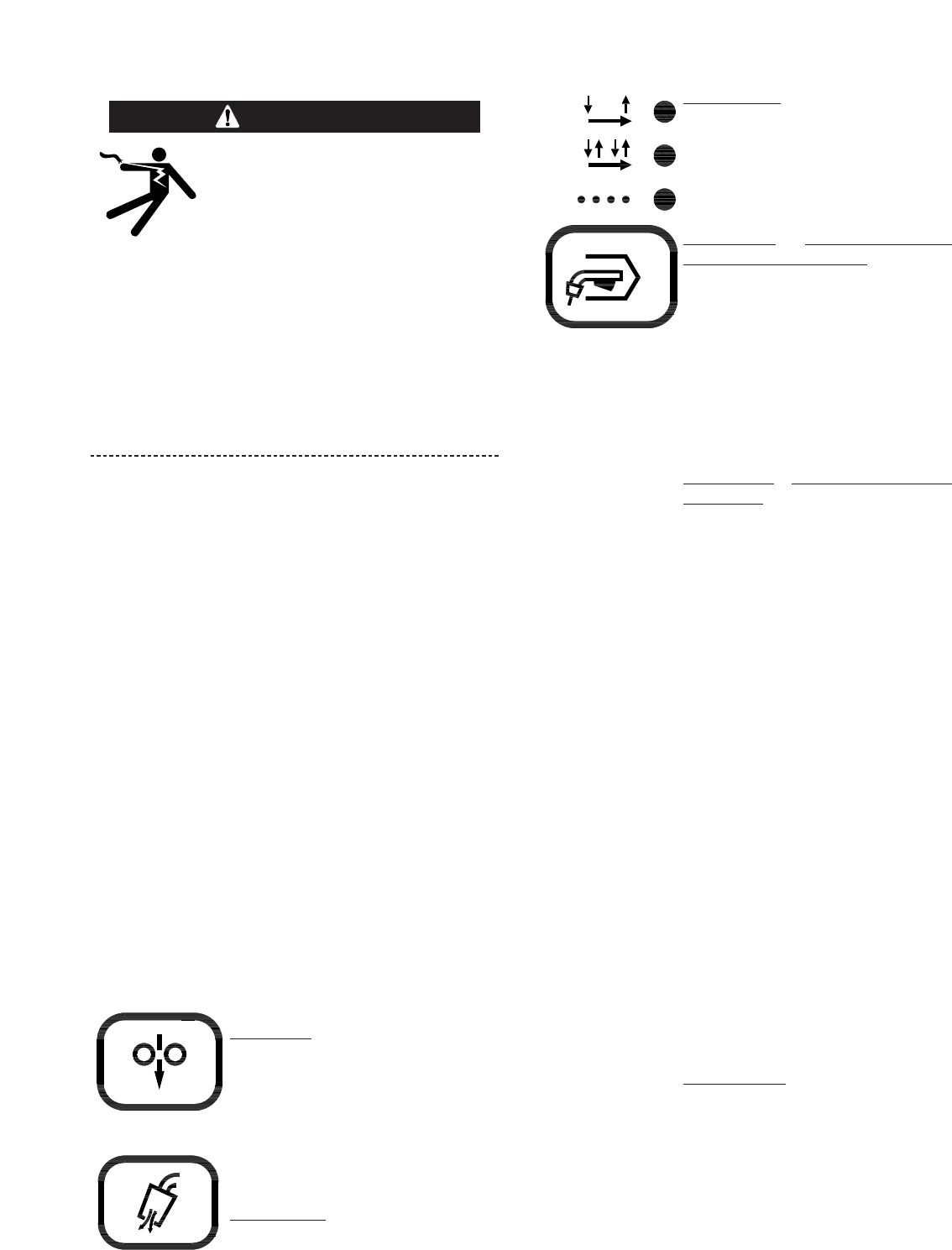

Mode Selection

Mode Select key enables operator

to choose mode of operation shown

by the indicator lights. Pressing key

causes mode lights to sequence

(top to bottom) starting from the

current indicated position.

Top Light

- Indicates 2-Step

(Standard) Trigger Mode.

1. Trigger closure energizes the

solenoid valve, then the wire feeder

and the power source after Preflow

time (See Timer/ Crater Section).

2. Releasing the trigger turns off the

wire feeder and power source and

then the solenoid valve after

Postflow time.

Middle Light - Indicates 4-Step (Lock)

Trigger Mode. These models have selectable

4-step with crater fill or, as shipped, 4-step

with current interlock. (See 4-step trigger

mode selection for method of switching).

The 4-step modes function as follows:

1. Trigger closure energizes the power

source and wirefeeder after the

preflow time.

2. Trigger release enables 4-step lock,

leaving the feeder and power source

as in step 1.

a) 4-step with current interlock will only

lock if weld current is flowing.

Breaking weld arc stops wire feed

and power source output.

b) 4-step with crater fill will lock without

welding.

3. Closing the trigger a second time

continues welding.

a) 4-step with current interlock

continues welding without changing

the settings from step 2.

b) 4-step with crater fill continues

welding but changes to the crater

settings.

4. Releasing the trigger turns off

wirefeeder and power source and

then gas solenoid after postflow

time.

Bottom Light - Indicates Spot Weld

Mode. Trigger closure energizes the

solenoid valve, then wire feeder and

the power source. The spot on timer

starts when current flows. The wire

feeder and power source then

solenoid valve are all turned off when

the spot on timer times out even

through the trigger is still closed.

COLD FEED

GAS PURGE

Operation Keys

Cold Feed key energizes the wire

feeder but not the power source or

solenoid valve. This cold feed

speed is digitally displayed and is

adjustable (with “Arrow keys”) only

while pressing the Cold Feed Key.

The last setting is held in memory

for next Cold Inch feeding.

Gas Purge

key energizes the

solenoid valve but not the wire

feeder or power source.

STD

LOCK

SPOT

2-STEP

4-STEP

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts such

as output terminals or internal wiring.

• When inching with gun trigger, electrode

and drive mechanism are “hot” to work

and ground.

• Turn OFF welding power source before

installing or changing drive roll and/or

guide tubes.

• Welding power source must be connected

to system ground per the National

Electrical Code or any applicable local

codes.

• Only qualified personnel should

perform this installation.

WARNING

Observe all additional Safety Guidelines detailed

throughout this manual.