A-3

INSTALLATION

DC-400

A-3

REMOTE CONTROL ADAPTER CABLE (K864)

A “V” cable 12” (.30m) long to connect a K857

Remote Control, K963 Hand Amptrol or K870 Foot

Amptrol (6-pin connector) with a wire-feeder (14-pin

connector) and the machine (14-pin connector). If a

remote control or amptrol is used alone the wire-feed-

er connection is then not used.

ELECTRIC SHOCK can kill.

• Turn the power switch of the welding

power source “OFF” before installing

plugs on cables or when connecting

or disconnecting plugs to welding

power source.

------------------------------------------------------------------------

AMPTROL™ ADAPTER CABLE (K843)

A five wire cable, 12” (.30m) long, is available for easy

connection of standard K963 Hand Amptrol or K870

Foot Amptrol. The cable has a 6-pin MS-style con-

nector which connects to the Amptrol and terminals

which connect to 75, 76 and 77 on the machine termi-

nal strip and to the case grounding screw. The

Amptrol will control the same range of output as the

current control on the welder. (If a smaller range of

control is desired for finer adjustment, a K775

Remote may be used in conjunction with the Amptrol

Adapter Cable Kit.) The Amptrol arc start switch is

nonfunctional unless used with a K799 Hi-Frequency

Kit.

K843 AMPTROL™ ADAPTER INSTALLA-

TION INSTRUCTION

For use with: DC-250, DC-400, R3R or Weldanpower

250 (D-10 and Pro) with remote control power

sources.

ELECTRIC SHOCK can kill.

• Turn the power switch of the welding

power source “OFF” before installing

plugs on cables or when connecting

or disconnecting plugs to welding

power source.

------------------------------------------------------------------------

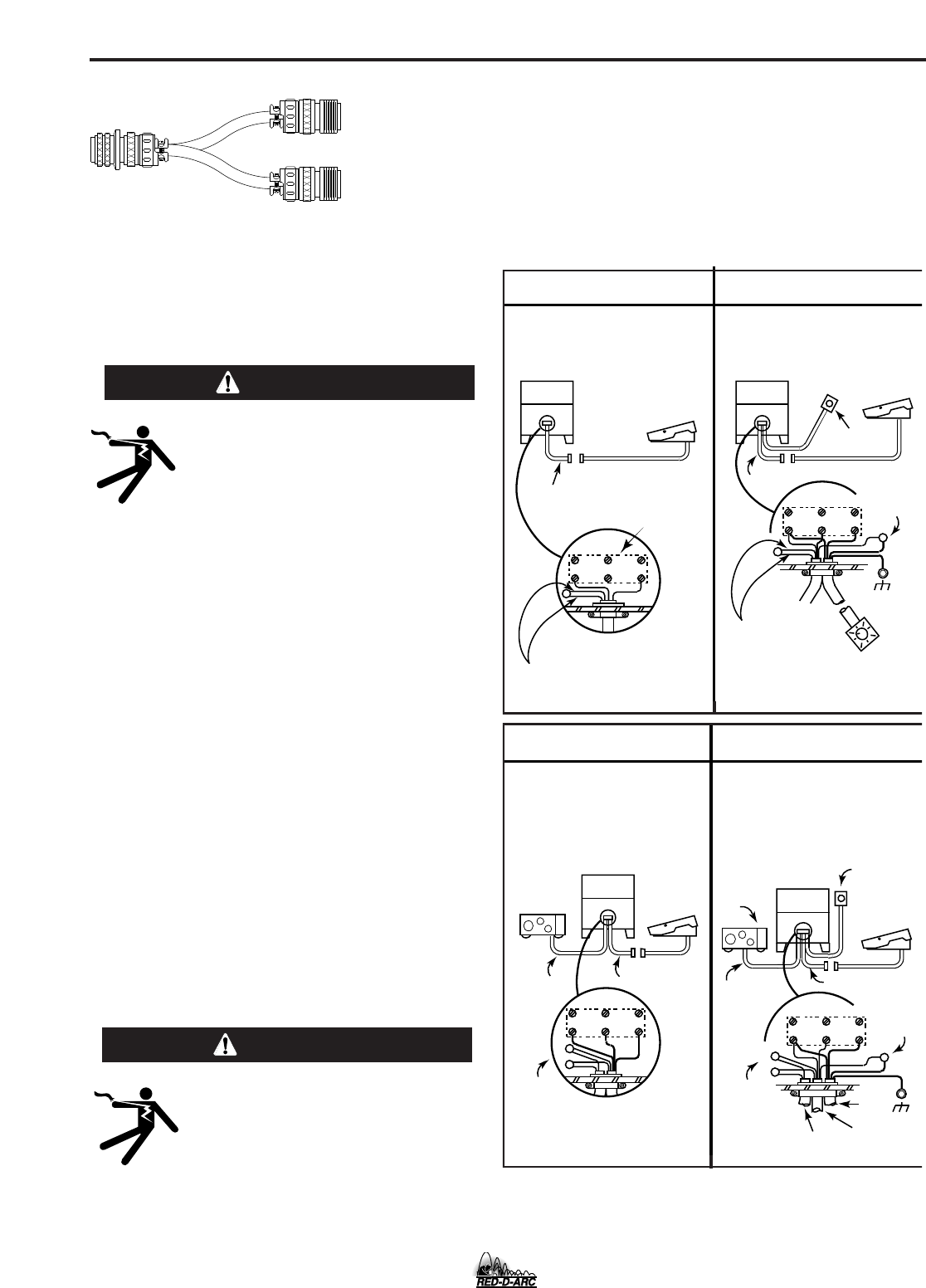

This K843 adapter is used to connect AMPTROL™

(K963*, K813* or K870), remote control (K775), and

HI-FREQ™ (K799) accessories to DC-250, DC-400,

R3R or Weldanpower 250 (D-10 and Pro) with remote

control power sources. The power source

"machine/remote" switch must be in "remote" for

Amptrol™ to control current. Accessories may be

combined and connected in four different ways, as

shown in Figure 1,2,3, & 4.

WARNING

WARNING

STRAIGHT PLUG (14 PIN)

TO POWER SOURCE

CABLE RECEPTACLE (6 SOCKET)

CABLE RECEPTACLE (14 SOCKET)

TO: 1) K857 REMOTE CONTROL

2) K963 HAND AMPTROL

3) K870 FOOT AMPTROL

TO LN-7 WIRE FEEDER

AMPTROL™ ONLY

AMPTROL™ PLUS

REMOTE LIMIT CONTROL

The Amptrol provides remote

current control through the full range

of the power source.

The Amptrol provides remote

current control from the minimum of

the power source to a maximum set

by the remote limit control.

POWER

SOURCE

75 76 77

K963*, K813* or

K870 Amptrol

Power source

terminal

strip

Black and white leads

not used. Tape

and insulate.

K843

Adapter

FIG. 1

75

76

77

POWER

SOURCE

K963*, K813* or

K870 Amptrol

K775 Remote

Limit Control

K843

Adapter

77

76

Black and white

leads not used.

Tape and

insulate.

Bolt and nut

connection.

Insulate

and tape.

FIG. 2

AMPTROL™ AND

HI-FREQ.™ KIT

AMPTROL™ AND HI-FREQ.™ KIT

PLUS REMOTE LIMIT CONTROL

The Amptrol will start the Hi-Freq

kit to turn on gas and high frequency

starting for DC TIG welding. The

Amptrol controls current through

the full range of the power source.

The Amptrol switch will start the

Hi-Freq kit to turn on gas and high

frequency starting for DC TIG

welding. The Amptrol controls

current from the minimum of the

power source to a maximum set by

the remote limit control.

POWER

SOURCE

75 7776

{

K963*,K813*

or K870

Amptrol

K799

Hi-Freq Kit

Arc start cable

(included with

K799)

K843 Adapter

CUT OFF

ARC START

SWITCH and connect black

lead to black and white

lead to white.

FIG. 3

POWER

SOURCE

75 7776

{

76

77

CUT OFF

ARC START

SWITCH and

connect black

lead to black and

white lead to white.

K799

K843

K775

FIG. 4

Bolt and nut

connection.

insulate

and tape.

Arc start cable

(included

with K799)

K963*,K813*

or K870

Amptrol

K843 Adapter

K775 Remote

Limit Control

K799

Hi-Freq

Kit