A-4

INSTALLATION

POWER WAVE AC/DC

A-4

WELDING WITH MULTIPLE UNSYN-

CHRONIZED POWER WAVES

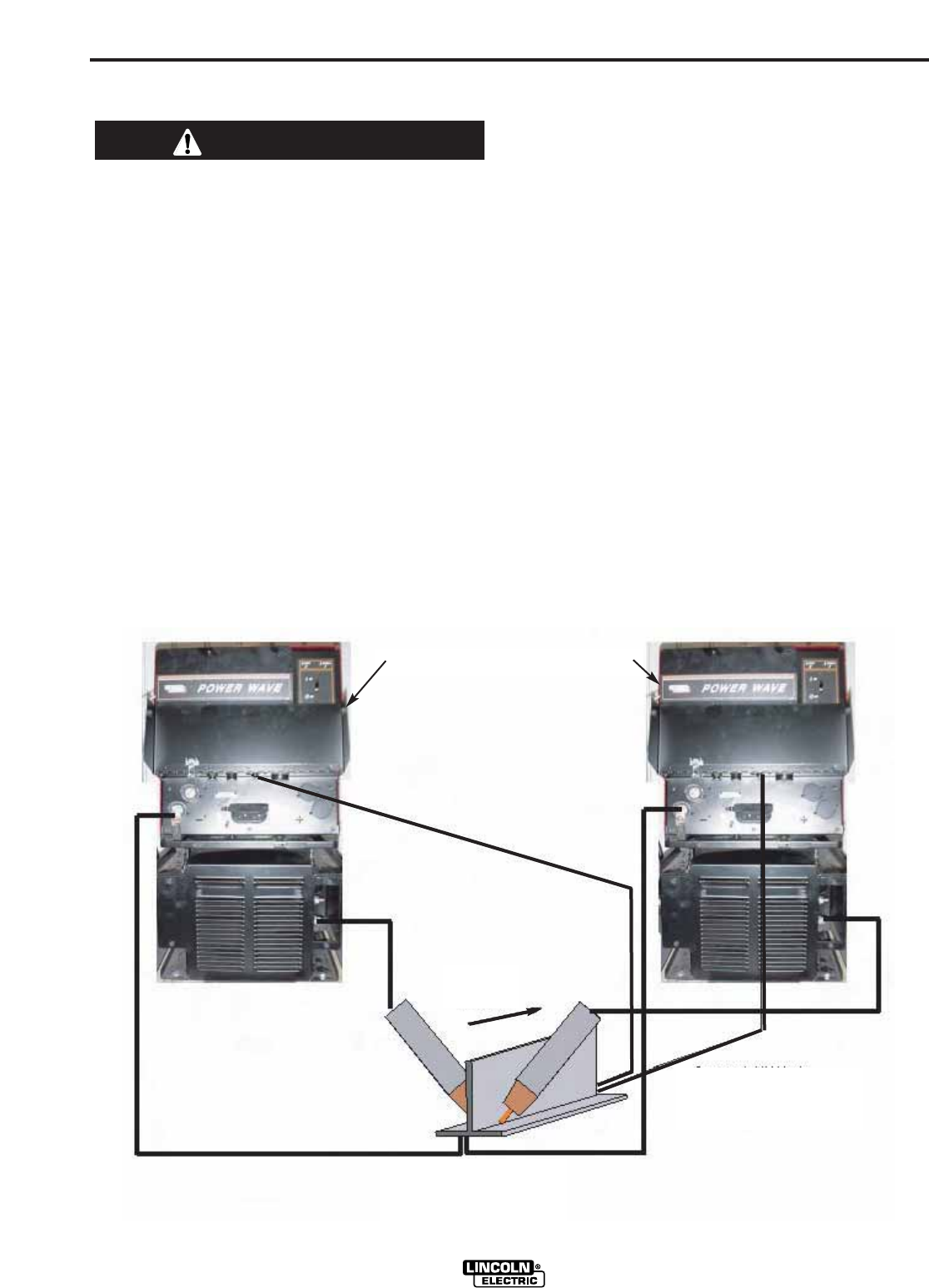

Special care must be taken when more than one

Power Wave is welding unsynchronized on a sin-

gle part. Arc blow and arc interference may occur

or be magnified. Each power source requires a

work lead to the work stud to the welding fixture.

Do not combine all of the work leads into one

lead. Performing welding in the direction away

from the work leads. (In a synchronized multi arc

system the weld should go towards the work

leads to minimize arc blow). Connect all of the

work sense leads from each power source to the

work piece at the end of the weld, such that they

are out of the path of the weld current. For addi-

tional information on work voltage sense leads

see sections entitled "Voltage Sensing" and

"Multiple Unsynchronized Arc Sense Lead and

Work Lead Placement Guidelines".

------------------------------------------------------------------------

TWO POWER WAVES

For the best results when pulse welding, set the wire

size and wire feed speed the same for all the Power

Waves. When these parameters are identical, the

pulsing frequency will be the same, helping to stabilize

the arcs.

Every welding gun requires a separate shielding gas

regulator for proper flow rate and shielding gas cover-

age. Do not attempt to supply shielding gas for two or

more guns from only one regulator.

If an anti-spatter system is in use then each gun must

have its own anti-spatter system. (See Figure A.2.)

CAUTION

FIGURE A.2

Travel

Direction

Connect All Work

Sense Leads at the End

of the Joint.

Connect All Welding

Work Leads at the

Beginning of the Joint.