A-5

INSTALLATION

WELDING ARMS

A-5

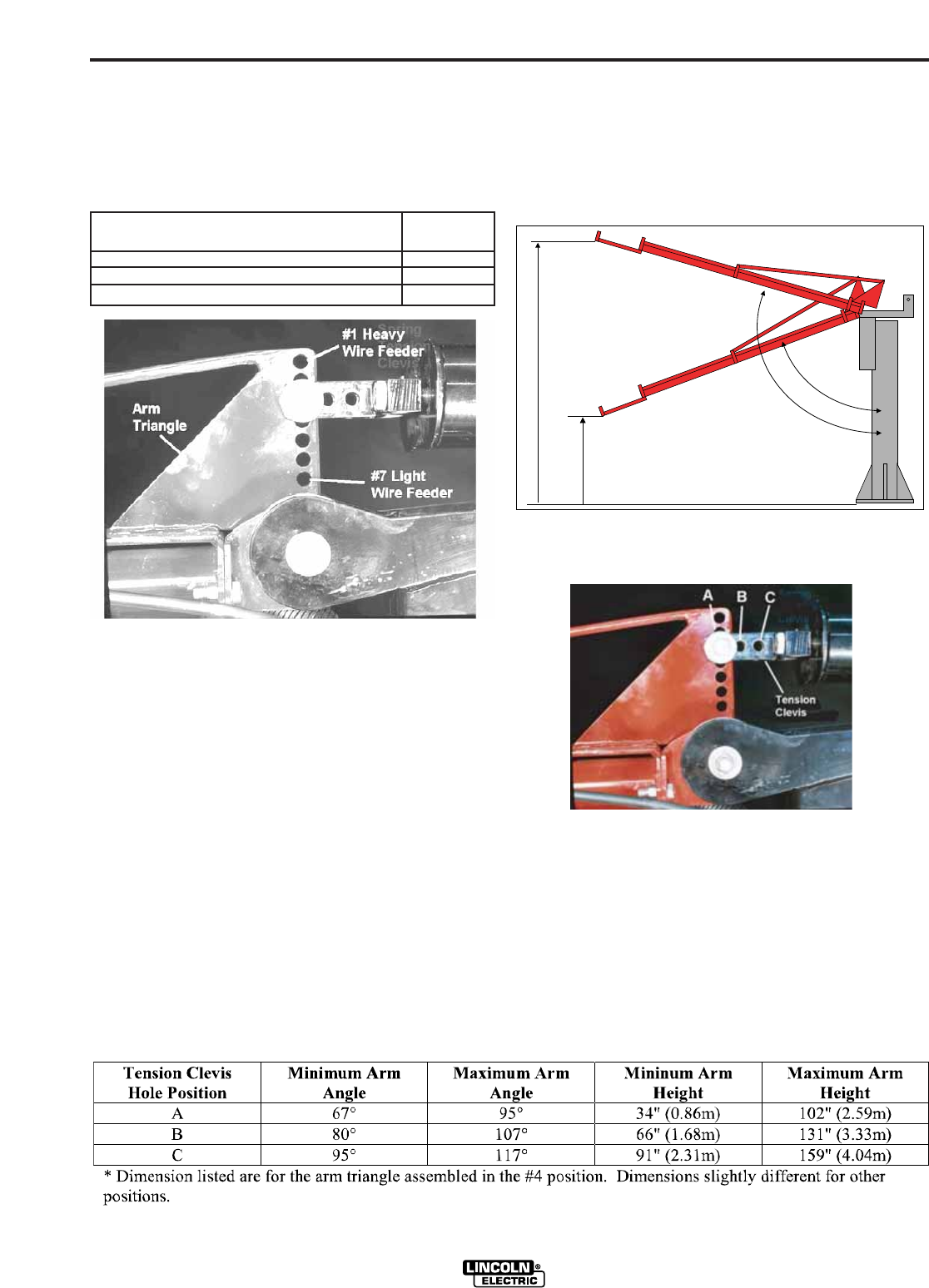

ADJUSTING FOR WIRE FEEDER WEIGHT

The holes in the arm triangle compensate for different

wire feeder weights. The top position, #1 is used for

heavy wire feeders. The bottom position, #7 is used

for light wire feeders.

Wire Feeder Arm triangle

hole position

LF-72 #5

LN-10, Power Feed 10, Power Feed 10M #4

DH-10, Power Feed 10 Dual, Power Feed 10M Dual #3

To change the arm triangle position:

1. Turn off power at the welding power source.

2. Support the welding arm with a fork lift or hoist.

3. Remove the tension clevis bolt.

4. Raise or lower the arm until the desired tension cle-

vis hole aligns with the desired arm triangle hole.

5. Replace the tension clevis bolt.

6. Remove the supporting equipment.

ADJUSTING THE WELDING ARM TRAVEL

(See Table A.2)

The holes in the tension clevis adjust the welding arm

travel range.

Most people prefer position A.

To change the tension clevis position:

7. Turn off power at the welding power source.

8. Support the weld arm with a fork lift or hoist.

9. Remove the tension clevis bolt.

10. Raise or lower the arm until the desired tension

clevis hole aligns with the desired arm triangle

hole.

11. Replace the tension clevis bolt.

12. Remove the supporting equipment.

Minimum

Arm Height

Maximum

Arm Height

Minimum

Arm Angle

Maximum

Arm Angle

TABLE A.2