E-12

TROUBLESHOOTING

E-12

POWER WAVE® i400

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

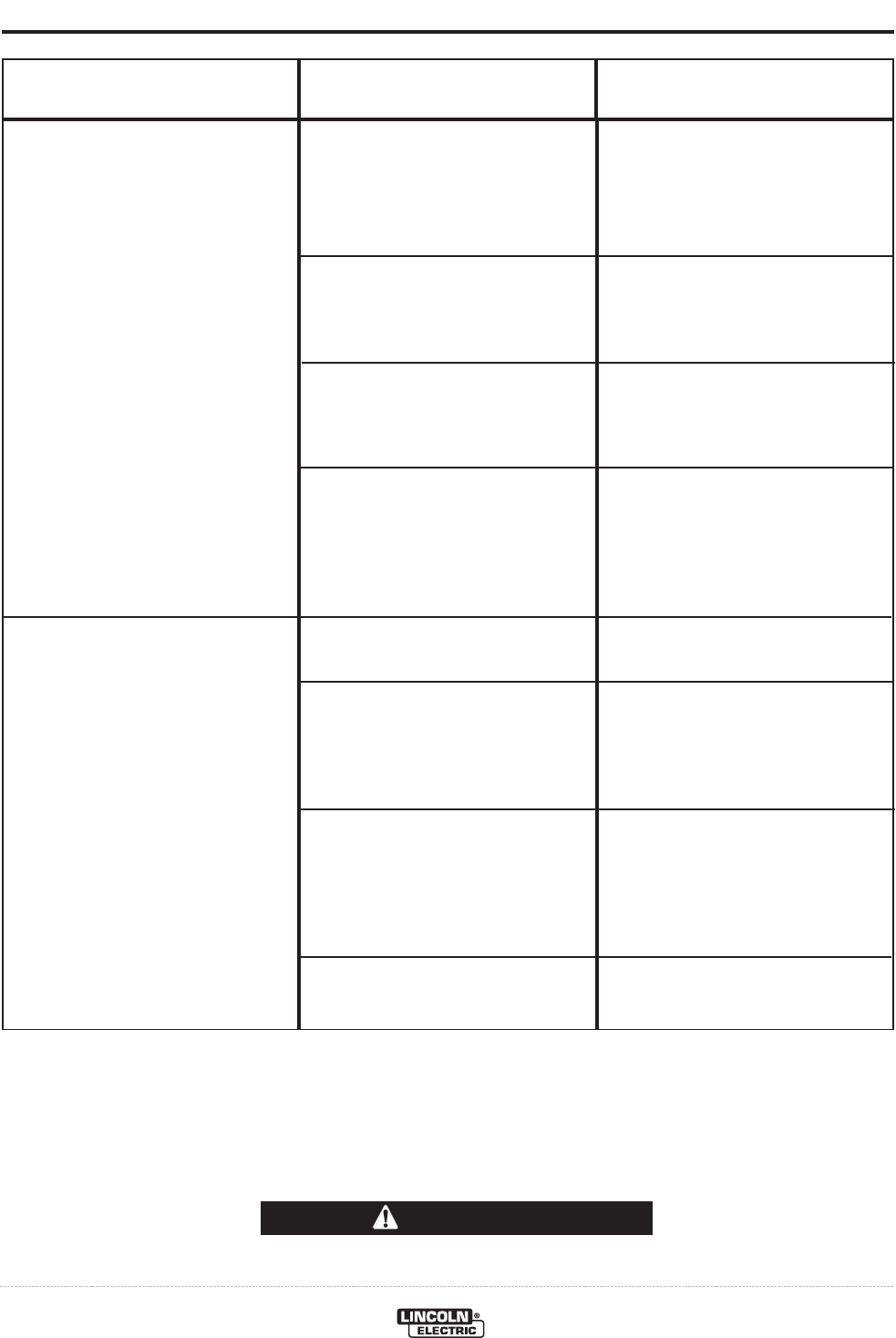

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Analog Inputs donʼt respond or donʼt

respond quickly.

Gas purge not working.

1. Analog Scans Between Updates.

2. Analog In Active Selections.

3. Analog Hysteresis.

4. Passive Mode.

1. Out of gas.

2. Gas Purge not asserted.

3. Passive Mode.

4. Gas Lines.

1. The DeviceNet tab of the Diagnostics

Utility displays the POWER WAVE®ʼs

“Analog Scans Between Updates” and

“I/O Scans/Sec.” Verify that “Analog

Scans Between Updates” is ¼ of “I/O

Scans/Sec” value.

2. From the DeviceNet tab of the

Diagnostics Utility, select Configure.

Verify in “Analog Input Channels” that

the required channels are set active.

3. From the DeviceNet tab of the

Diagnostics Utility, select Configure.

Verify in “Analog Input Channels” that

the Hysteresis settings are all 0.

4. The DeviceNet tab of the Diagnostics

Utility displays the POWER WAVE®ʼs

passive mode status. If the status

needs to be changed, select

Configure, and make the necessary

modification.

1. Verify there is gas available at the

input of the gas solenoid.

2. From the DeviceNet tab of the

Diagnostics Utility, select Monitor. The

Monitor window will be displayed.

Verify under the “Produced Assembly”

that “Gas Purge” is highlighted.

3. The DeviceNet tab of the Diagnostics

Utility displays the POWER WAVE®ʼs

passive mode status. If the status

needs to be changed, select

Configure, and make the necessary

modification.

4. Verify nothing is obstructing the flow

of gas.