B-2

OPERATION

B-2

PRODUCT DESCRIPTION

PRODUCT SUMMARY

The POWER WAVE® R350 is a portable multi-

process power source with high-end functionality

capable of DC TIG, MIG, Pulsed MIG and Flux-Cored

welding. It is ideal for a wide variety of materials

including aluminum, stainless, and nickel — where arc

performance is critical. The Power Wave® R350

includes an integrated wire drive module and 14-pin

MS-Style connection to support the PF-10R, and Auto

Drive 4R100/4R220.

The POWER WAVE® R350 is designed to be a flexi-

ble welding system. Like existing Power Waveʼs, the

software based architecture allows for future

upgrades. ArcLink® communication is supported

through the standard 5 pin MS-style interface. The

new ArcLink®XT communication protocol is supported

through an RJ-45 type Ethernet connection, which

also provides access for the Power Wave Utilities soft-

ware tools. The Ethernet communication also gives

the POWER WAVE® R350 the ability to run

Production Monitoring™ 2. Also Available is a

Devicenet option to allow the Power Wave® R350 to

be used in a wide range of configurations. The

POWER WAVE® R350 is being designed to be com-

patible with advanced welding modules like STT.

Access to remote voltage sensing is available through

the 4 pin sense lead connector (work and electrode),

at the feeder via the 14 pin MS-style connector (elec-

trode only), or at the 5 pin MS-style ArcLink® connec-

tor (electrode only).

RECOMMENDED PROCESSES AND

EQUIPMENT

The

POWER WAVE® R350

is recommended for robotic

and semiautomatic welding. The

POWER WAVE® R350

can be set up in a number of configurations, some requiring

optional equipment or welding programs.

RECOMMENDED EQUIPMENT

The POWER WAVE® R350 is designed to be com-

patible with the current range of Power Feed™ and

Auto Drive systems including future versions of

ArcLink® feeders.

RECOMMENDED PROCESSES

The POWER WAVE® R350 is a high speed, multi-

process power source capable of regulating the cur-

rent, voltage, or power of the welding arc. With an out-

put range of 5 to 350 amperes, it supports a number

of standard processes including synergic GMAW,

GMAW-P, FCAW, FCAW-SS, GTAW and GTAW-P

on various materials especially steel, aluminum and

stainless.

PROCESS LIMITATIONS

The software based weld tables of the POWER

WAVE® R350 limit the process capability within the

output range and the safe limits of the machine. In

general the processes will be limited to .030-.052 solid

steel wire, .030-.045 stainless wire, .035-1/16 cored

wire, and .035 and 1/16 Aluminum wire.

EQUIPMENT LIMITATIONS

Only ArcLink compatible robotic wire feeders, semiau-

tomatic wire feeders and users interfaces may be

used. If other Lincoln wire feeders or non-Lincoln wire

feeders are used there will be limited process capabili-

ty and performance and features will be limited.

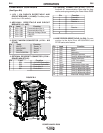

POWER WAVE® R350