B-7

OPERATION

B-7

Most pulse welding programs are synergic. As the

wire feed speed is adjusted, the POWER WAVE®

R350 will automatically recalculate the waveform

parameters to maintain similar arc properties.

The POWER WAVE® R350 utilizes “adaptive control”

to compensate for changes in the electrical stick-out

while welding. (Electrical stick-out is the distance

from the contact tip to the work piece.) The POWER

WAVE® R350 waveforms are optimized for a 0.75”

stick-out. The adaptive behavior supports a range of

stick-outs from 0.50 to 1.25”. At very low or high wire

feed speeds, the adaptive range may be less due to

reaching physical limitations of the welding process.

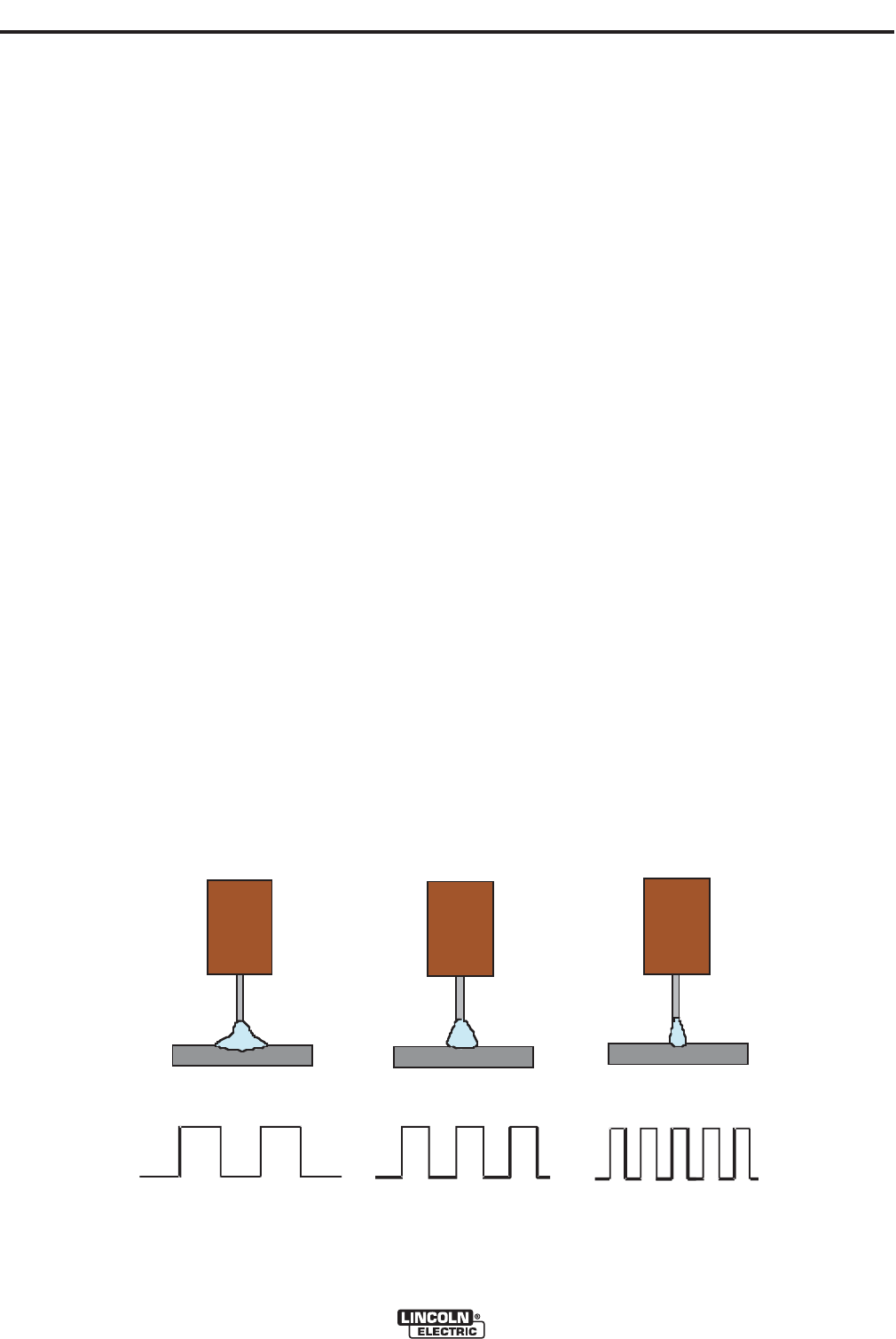

UltimArc™ Control adjusts the focus or shape of the

arc. UltimArc™ Control is adjustable from -10.0 to

+10.0 with a nominal setting of 0.0. Increasing the

UltimArc™ Control increases the pulse frequency and

background current while decreasing the peak cur-

rent. This results in a tight, stiff arc used for high

speed sheet metal welding. Decreasing the

UltimArc™ Control decreases the pulse frequency

and background current while increasing the peak cur-

rent. This results in a soft arc good for out of position

welding. (See Figure B.4)

POWER WAVE® R350

OFF

Medium Frequency and Width

+10.0

High Frequency , Fo cused

UltimArc™ Control -10.0

Low Frequency, Wide

UltimArc™ Control

UltimArc™ Control

FIGURE B.4