B-4

OPERATION

B-4

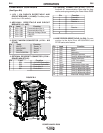

CASE BACK CONTROLS

(See Figure B.2)

1. 115V / 15A DUPLEX RECEPTACLE AND

CIRCUIT BREAKER 1 (10 AMP): Provides protec-

tion for the 115V auxiliary.

2. ARCLINK® RECEPTACLE AND CIRCUIT

BREAKER 2 (10 AMP):

Pin Lead Function

A 53A / 53B Communication Bus L

B 54A / 54B Communication Bus H

C 67A / 67B Electrode Voltage Sense

D 52A / 52B +40V DC

E 51A / 51B 0 VDC

3. SYNC-TANDEM CONNECTOR (4 PIN – MS

STYLE):

Pin Lead Function

A WHITE “Ready” H

B BLACK/RED “Ready” L

C GREEN “Kill” H

D BLACK/GREEN “Kill” L

4. OPTIONAL DEVICENET CONNECTOR (5 PIN –

SEALED MINI STYLE):

Pin Lead Function

2 894 +24 VDC DeviceNet

3 893 Common DeviceNet

4 892 DeviceNet H

5 891 DeviceNet L

5. ETHERNET CONNECTOR (RJ-45): Used for

ArcLink® XT communication. Also used for diag-

nostics and reprogramming the Power Wave R350.

Pin Function

1 Transmit +

2 Transmit -

3 Receive +

4 ---

5 ---

6 Receive -

7 ---

8 ---

6. WIRE FEEDER RECEPTACLE (14-PIN): For con-

nection to the Auto Drive 4R100/4R220 and

PF10R series wire feeders.

Pin Lead Function

A 539 Motor +

B 541 Motor -

C 521 Solenoid +

D 522 Solenoid Common

E 845 Tach 2A differential signal

F 847 Single Tach input

G 841 +15V Tach supply

H 844 Tach common

I Open Reserved for future use

J Open Reserved for future use

K 842 Tach 1A differential signal

L 843 Tach 1B differential signal

M 846 Tach 2B differential signal

N 67G Electrode Voltage Sense

POWER WAVE® R350

1

2

3

4

5

6

FIGURE B.2