B-6

OPERATION

B-6

GTAW (TIG) WELDING

The welding current can be set through a PF10M or

PF25M wire feeder.

The TIG mode features continuous control from 5 to

350 amps with the use of an optional foot amptrol

(K870). The POWER WAVE® R350 can be run in

either a Touch Start TIG mode or Scratch start TIG

mode.

CONSTANT VOLTAGE WELDING

Synergic CV

For each wire feed speed, a corresponding voltage is

preprogrammed into the machine through special soft-

ware at the factory.

The nominal preprogrammed voltage is the best aver-

age voltage for a given wire feed speed, but may be

adjusted to preference. When the wire feed speed

changes, the Power Wave automatically adjusts the

voltage level correspondingly to maintain similar arc

characteristics throughout the WFS range.

Non Synergic CV

In non-synergic modes, the WFS control behaves

more like a conventional CV power source where

WFS and voltage are independent adjustments.

Therefore to maintain the arc characteristics, the oper-

ator must adjust the voltage to compensate for any

changes made to the WFS.

All CV Modes

Pinch adjusts the apparent inductance of the wave

shape. The “pinch” function is inversely proportional

to inductance. Therefore, increasing Pinch Control

greater than 0.0 results in a crisper arc (more spatter)

while decreasing the Pinch Control to less than 0.0

provides a softer arc (less spatter).

PULSE WELDING

Pulse welding procedures are set by controlling an

overall “arc length” variable. When pulse welding, the

arc voltage is highly dependent upon the waveform.

The peak current, back ground current, rise time, fall

time and pulse frequency all affect the voltage. The

exact voltage for a given wire feed speed can only be

predicted when all the pulsing waveform parameters

are known. Using a preset voltage becomes impracti-

cal and instead the arc length is set by adjusting

“trim”.

Trim adjusts the arc length and ranges from 0.50 to

1.50 with a nominal value of 1.00. Trim values greater

than 1.00 increase the arc length, while values less

than 1.00 decrease the arc length. (See figure B.3)

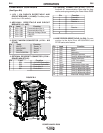

POWER WAVE® R350

Trim .50

Arc Length Short

Trim 1.00

Arc Length Medium

Trim 1.50

Arc Length Long

FIGURE B.3