Repair

P 6 / 13

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Torque Limiter Section (cont.)

ASSEMBLING

Do the reverse of disassembling steps.

Note: Do not forget to assemble Flat washer 28 between Torque limiter section and Inner housing complete. Refer to Fig. 12.

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Needle Bearing Complete and Oil Seal 25

DISASSEMBLING

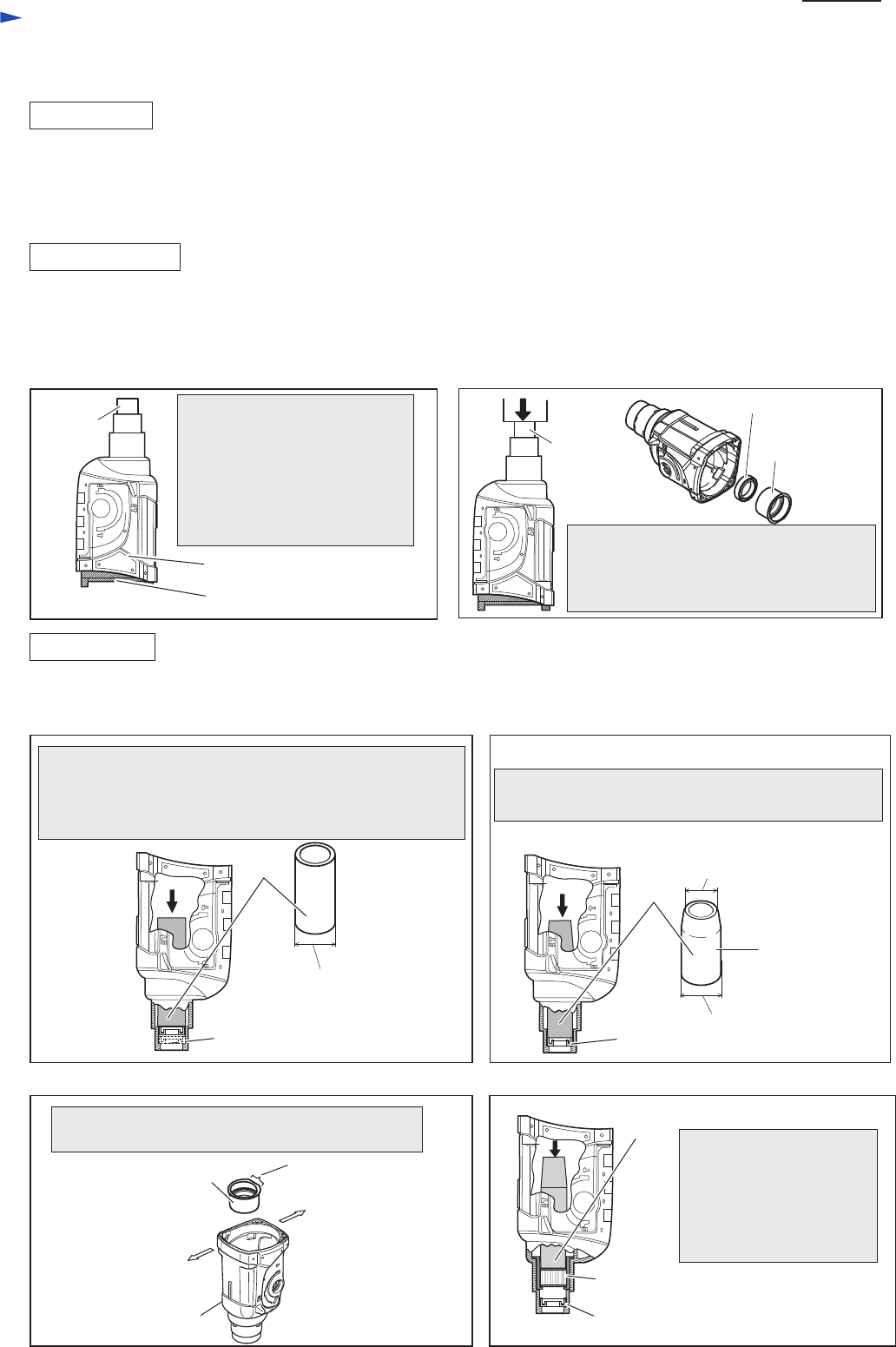

Applying 1R252, press it with Arbor press.

Needle bearing complete is removed

together with Oil seal 25 from Gear

housing complete.

1R252

1R252

Oil seal 25

Needle bearing

complete

Fig. 16

Fig. 15

1) Disassemble Torque limiter section and Inner housing complete from Gear housing complete.

See Disassembly of [3] -5. Torque Limiter Section.

2) Insert Inner housing complete into Gear housing complete. (Fig. 15)

3) Remove Needle bearing complete and Oil seal 25. (Fig. 16)

Inner housing complete

Gear housing complete

As the side for joining to Motor

housing is not flat, Gear housing

complete can not stand vertically

without support.

Therefore, insert Inner housing

complete into Gear housing

complete as a support.

ASSEMBLING

Fig. 20

Fig. 19

1) Assemble Oil seal 25 to Gear housing complete in the order of Figs. 17 and 18.

2) Assemble Needle bearing complete as illustrated in Figs. 19 and 20.

1R164

1R164

1R164

outer diameter: 30mm

outer diameter: 34mm

1R232

Oil seal 25

With 1R232 and arbor press, insert Oil seal 25 until it stops.

Oil seal 25 is not yet inserted completely in this step,

because the outer diameter of 1R232 is bigger than that of

Oil seal setting hole.

The initial position of Oil seal 25

Oil seal 25

The diameter of Oil seal 25 setting

hole is less than 36mm.

outer diameter: 36mm

back side

Gear housing complete

belly side

Needle bearing complete

Press Needle bearing with

arbor press and the outer

diameter 34mm end

surface of 1R164 until

Needle bearing complete

stops.

Fig. 17 Fig. 18

Face the flat portion of Needle bearing complete to

the belly side of Gear housing complete.

Needle bearing complete

flat portion

Press Oil seal 25 to the initial position with arbor press

and the outer diameter 34mm end surface of 1R164.