. A complete Parts List is available at www.MillerWelds.com

OM-4419 Page 21

! Stop engine.

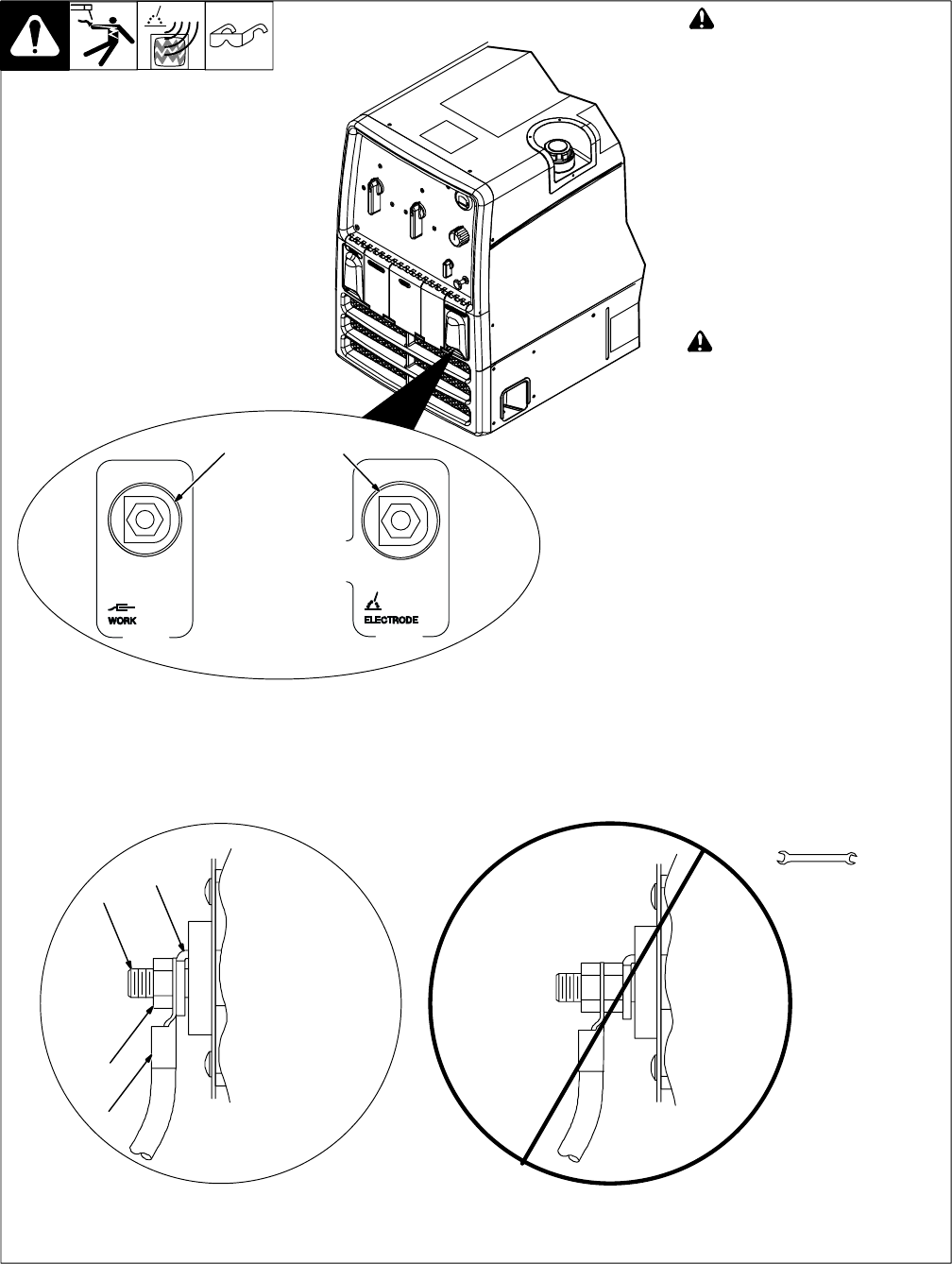

1 Work Weld Output Terminal

2 Electrode Weld Output Terminal

Connect work cable to Work terminal.

Connect electrode holder cable or

electrode weld cable to Electrode ter-

minal for Stick and MIG welding.

Connect torch cable to Electrode ter-

minal for TIG welding.

Use Process Selector switch to

select type of weld output (see

Section 6-1).

. See Sections 6-3 thru 6-5 for typi-

cal process connections and

control settings.

! Failure to properly connect

weld cables may cause exces-

sive heat and start a fire, or

damage your machine.

3 Weld Output Terminal

4 Supplied Weld Output Terminal

Nut

5 Weld Cable Terminal

6 Copper Bar

Remove supplied nut from weld out-

put terminal. Slide weld cable terminal

onto weld output terminal and secure

with nut so that weld cable terminal is

tight against copper bar. Do not

place anything between weld cable

terminal and copper bar. Make

sure that the surfaces of the weld

cable terminal and copper bar are

clean.

5-6. Connecting to Weld Output Terminals

803 750-B / Ref. 228 201-B / 803 778-A

Tools Needed:

3/4 in

6

4

5

Do not place

anything between

Correct Installation

Incorrect Installation

3

weld cable terminal

and copper bar.

1 2