. A complete Parts List is available at www.MillerWelds.com

OM-4419 Page 25

ELECTRODE

DC*

AC

POSITION

PENETRATION

USAGE

MIN. PREP, ROUGH

HIGH SPATTER

GENERAL

SMOOTH, EASY,

FAST

LOW HYDROGEN,

STRONG

SMOOTH, EASY,

FASTER

CAST IRON

STAINLESS

DEEP

DEEP

LOW

MED

LOW

LOW

LOW

LOW

ALL

ALL

ALL

ALL

ALL

FLAT

HORIZ

FILLET

ALL

ALL

EP

EP

EP,EN

EP,EN

EP

EP,EN

EP

EP

6010

6011

6013

7014

7018

7024

NI-CL

308L

*EP = ELECTRODE POSITIVE (REVERSE POLARITY)

EN = ELECTRODE NEGATIVE (STRAIGHT POLARITY)

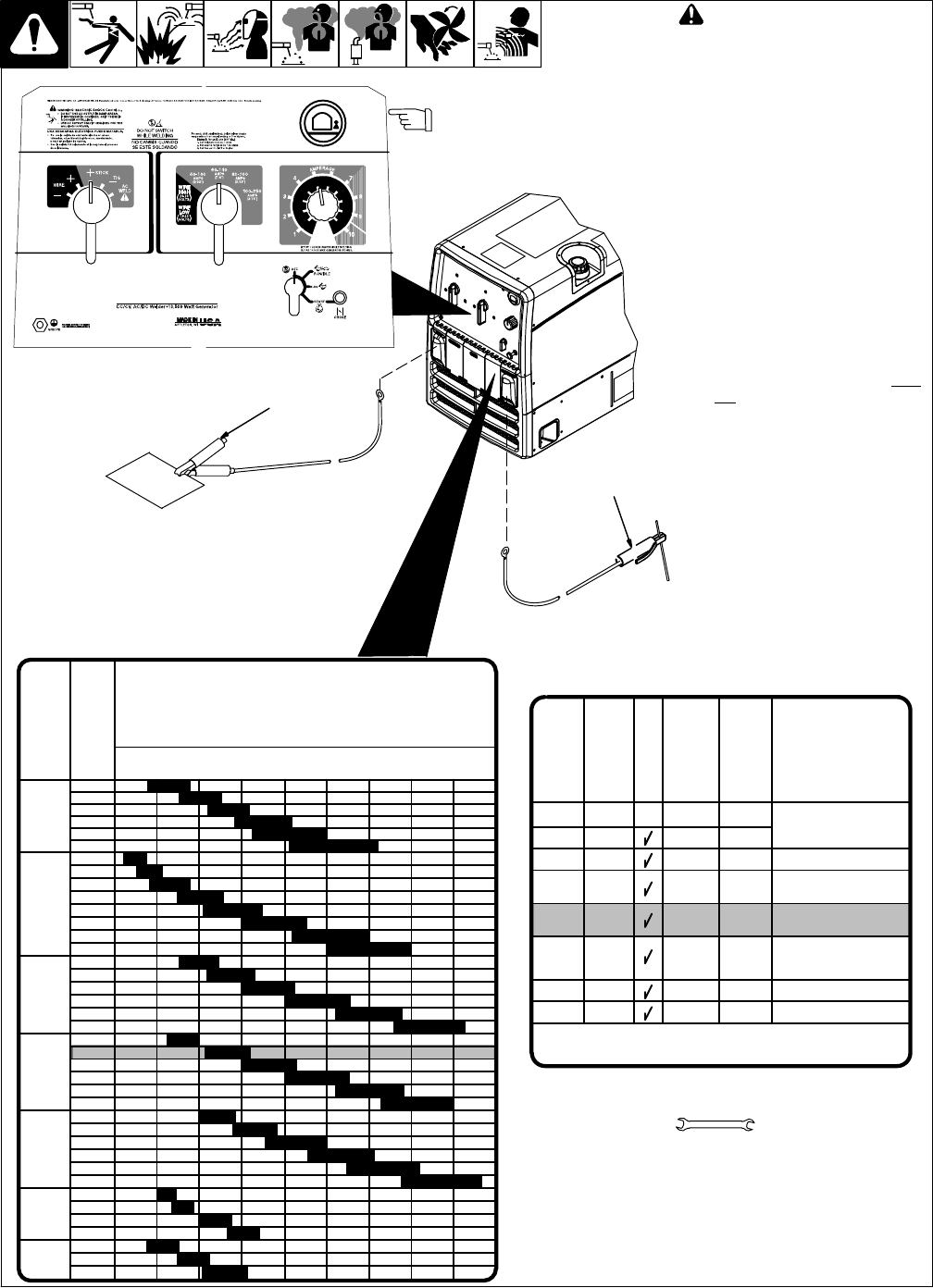

6-3. Typical Stick Welding Connections And Control Settings

803 750-B / 228 201-B / 087 985-A / Ref. S-0653

! Stop engine.

. This section provides general

guidelines and may not suit all

applications.

. The control panel shows the typi-

cal settings for welding with a

7018 (1/8 in) electrode. Consult

the amperage selection tables

below if welding with other elec-

trodes.

1 Work Clamp

2 Electrode Holder

Connect Work cable to Work terminal

and Electrode holder cable to Elec-

trode terminal on welding generator.

. Be sure to use the correct size

weld cables (see Section 5-7).

. For best performance, set the

Coarse Range switch to the low-

est range that covers the desired

weld amperage. Use the Fine

control to select the desired am-

perage within the range se-

lected. When properly set, the

Fine control is normally set at 7

or higher.

Typical Settings For 7018 (1/8 in)

Electrode:

> Set Weld Process Selector

switch to + Stick position.

> Set Coarse Range switch to

60-140 (1/8”) position.

> Set Fine control at 7 or higher

for best results.

1

2

3/32

1/8

5/32

3/16

7/32

1/4

1/16

5/64

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

3/32

1/8

5/32

6010

&

6011

6013

7014

7018

7024

Ni-Cl

308L

50

100

150

200

250

300

350

400

450

ELECTRODE

AMPERAGE

RANGE

DIAMETER

Electrode Selection Table (Beneath Cover)

Tools Needed:

For best arc starts and best

results using weld and generator

power together, use a low

Coarse Range setting and the

Fine control set at 7 or higher.

3/4 in

Typical Settings For 7018 (1/8 in) Electrode