. A complete Parts List is available at www.MillerWelds.com

OM-4419 Page 24

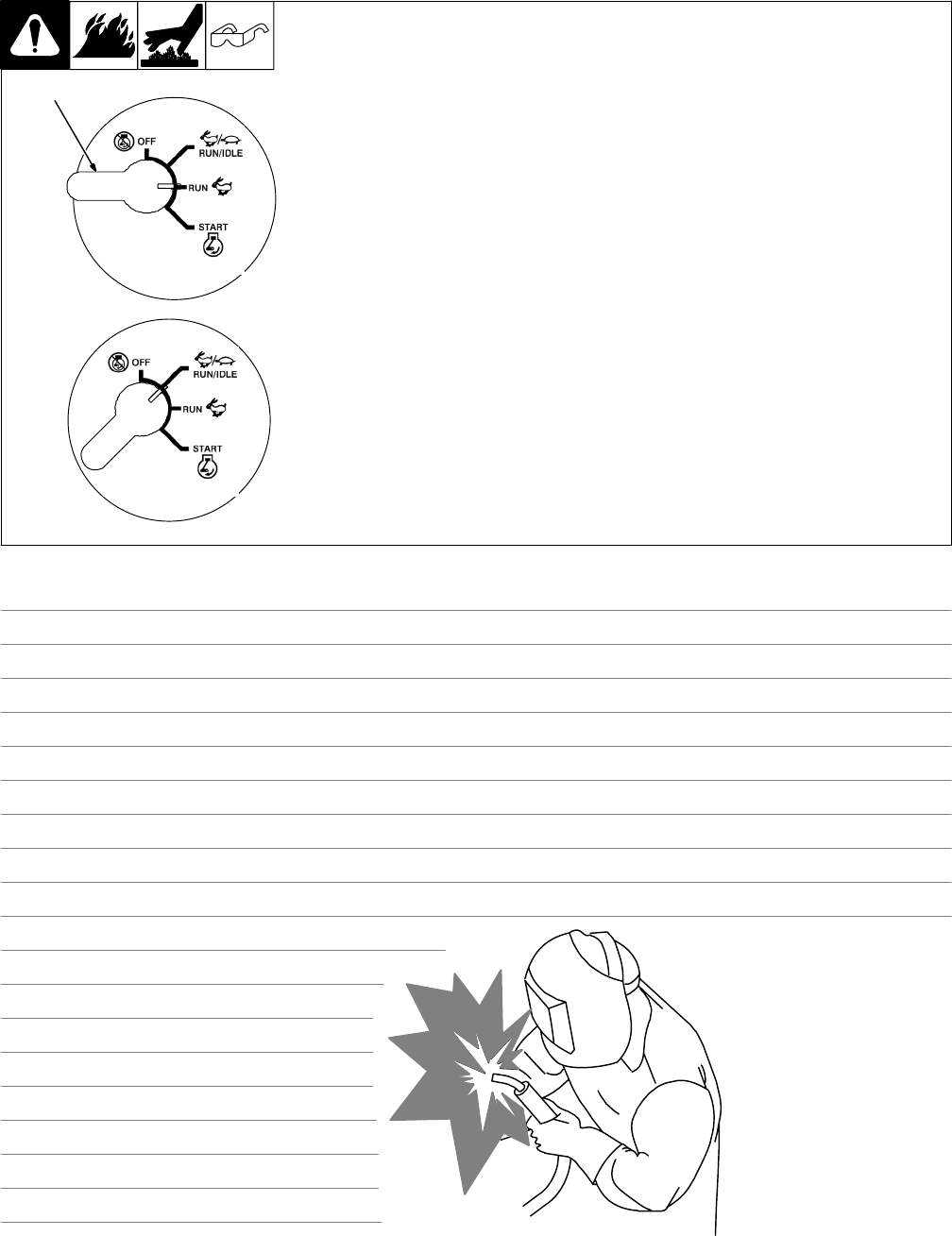

6-2. Cold Weather Engine Operation

Ref. 228 201-B

1 Engine Control Switch

Carburetor Icing

Carburetor icing causes the unit to drop below the normal idle speed and then

stall. This condition occurs when the temperature is near freezing and the rela-

tive humidity is high. Ice forms on the throttle plate and inner bore of the carbu-

retor. The engine typically restarts without problems but soon stalls again.

S Treat gasoline with a fuel de−icer product (isopropyl alcohol).

S Place the Engine Control switch in the Run position.

S Run engine only when expecting to frequently load it.

Breather Icing

Oil breather/pulse line icing occurs in severe cold (continuously below 0_F).

Moisture accumulates in the oil from piston ring blow−by if the engine is exten-

sively idled. This may cause vacuum line freezing, oil breather tube freezing

or ice in the carburetor. All of these cause operating problems. Due to ice in

the lines, the engine may not restart until it is warmed to above freezing.

S Load engine and reduce idle times to prevent engine shutdowns.

S Use an electric fuel pump to avoid pulse line freezing.

S Install engine cold−weather kit.

Both Kohler (1-800-544-2444) and Robin (1-800-277-6246) offer kits for cold

weather operation. The user can install these kits. Both kits pull heated air from

the muffler surface into the carburetor and shut the cold air off. This increases

engine temperature during operation in both idle and high speed.

. When the ambient temperatures become warmer (above 45_F) the air

flow will have to be returned to normal.

1

Frequently

Loaded

Infrequently

Loaded

Notes

Work like a Pro!

Pros weld and cut

safely. Read the

safety rules at

the beginning

of this manual.