OM-4411 Page 21

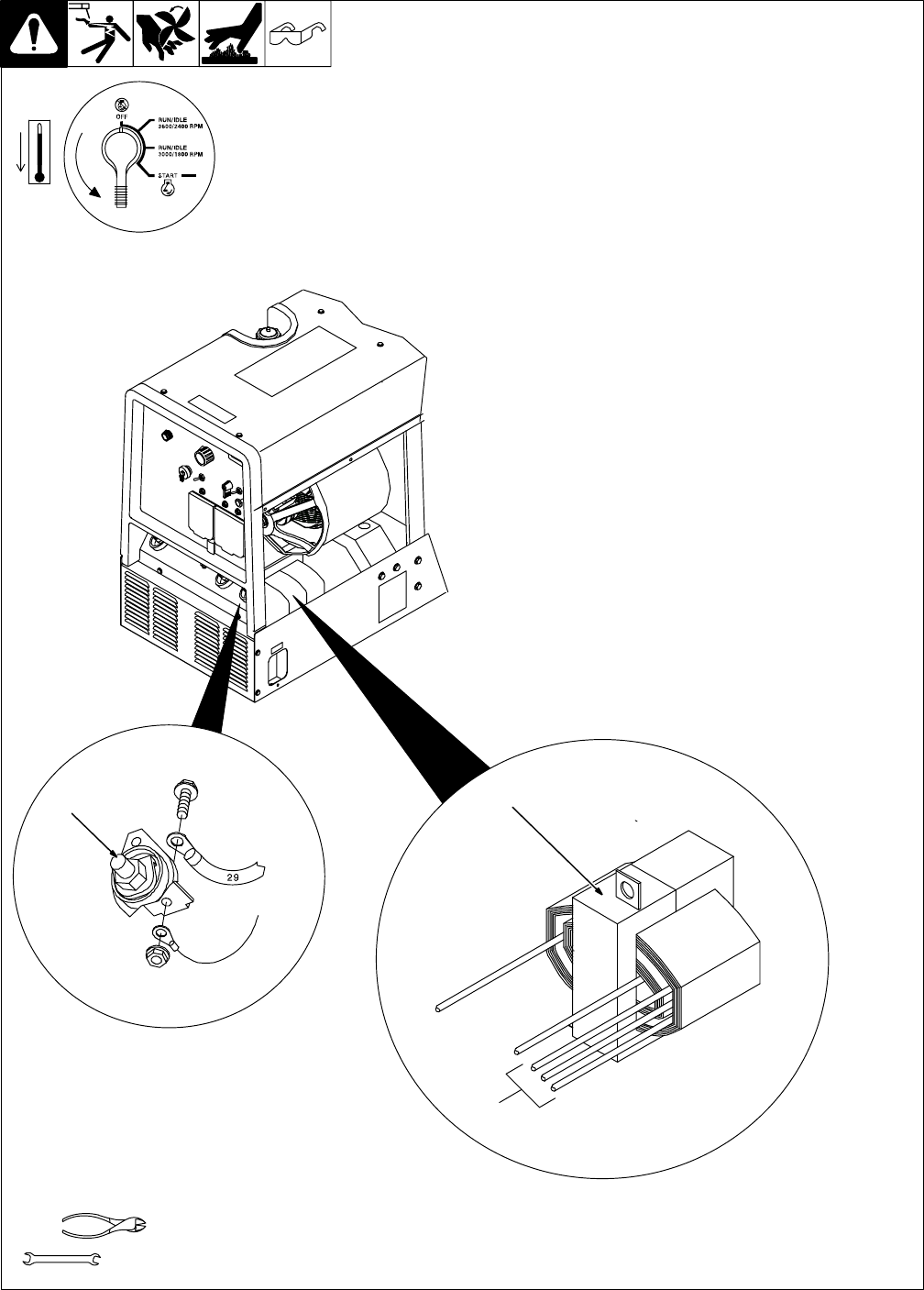

5-9. Adjusting Wire (MIG) Weld Puddle Consistency

Ref. 803 100

3/8, 7/16 in

Tools Needed:

1

2

3

Y Stop engine and let cool.

Stabilizer DC-Z is factory connected to

suit most Wire (MIG) welding applica-

tions.

To change Wire (MIG) weld puddle con-

sistency, proceed as follows:

Remove cover and right side panel.

1 Stabilizer DC-Z

2 Wire /CV Weld Output Terminal

3 Stabilizer Leads 29, 28, And 27

Lead 29 − provides stiffest weld

puddle

Lead 28 − provides wetter weld

puddle (for mild steel)

Lead 27 − provides wettest weld

puddle (for stainless steel)

Lead 29 is connected to the Wire/CV

weld output terminal at the factory.

Disconnect lead 29 from the Wire/CV

weld output terminal.

For wetter weld puddle (for mild

steel):

Remove insulated sleeving from lead

28. Connect lead 28 to Wire/CV weld

output terminal, reusing hardware. Insu-

late lead 29 with sleeving removed from

lead 28. Secure sleeving with cable ties.

For wettest weld puddle

(for stainless steel):

Remove insulated sleeving from lead

27. Connect lead 27 to Wire/CV weld

output terminal, reusing hardware. Insu-

late lead 29 with sleeving removed from

lead 27. Secure sleeving with cable ties.

Reinstall side panel.