OM-4411 Page 23

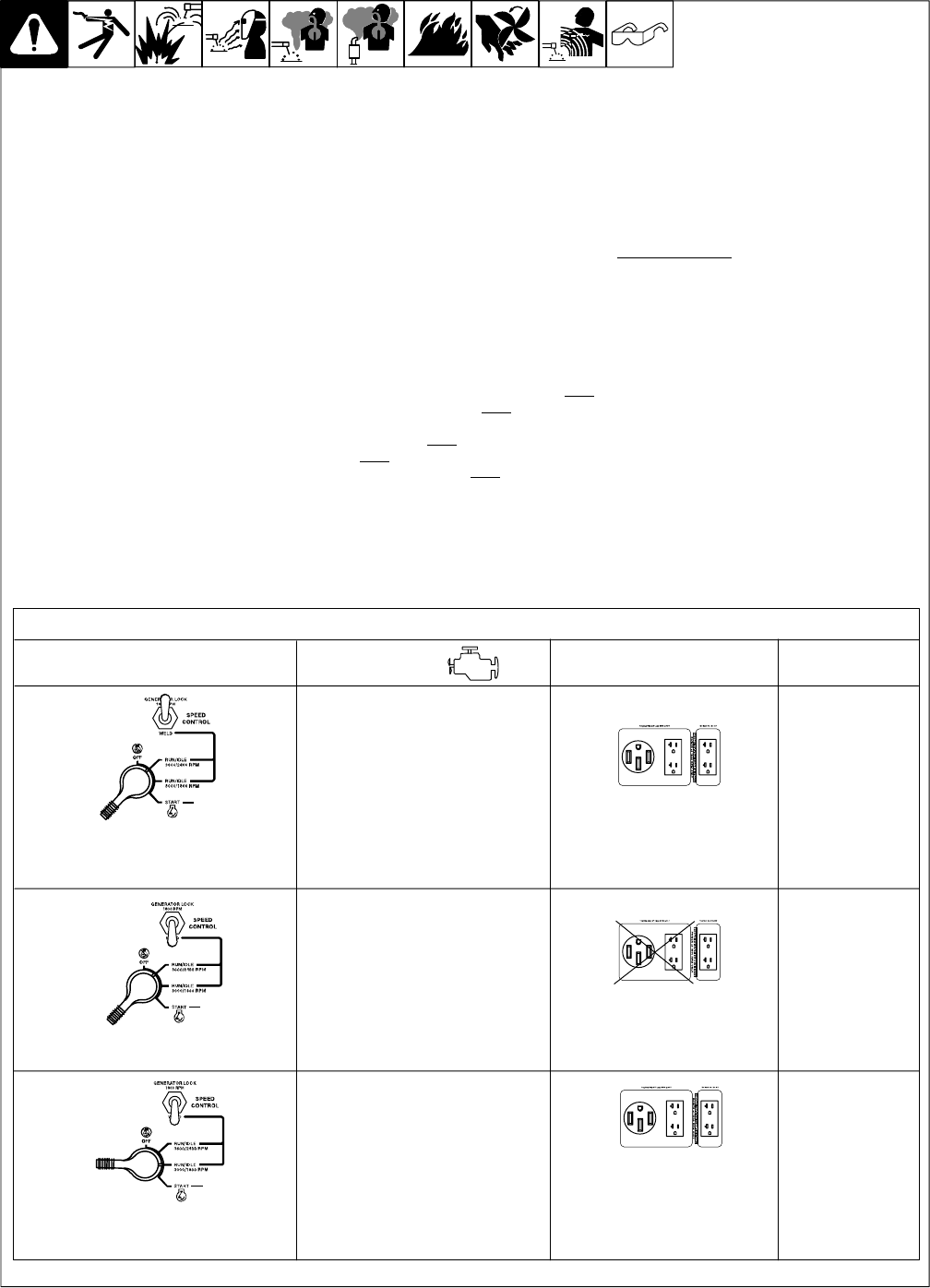

6-2. Description Of Front Panel Controls

1 Process Switch

See Section 6-3 for Process switch informa-

tion.

2 Voltage/Amperage Adjust Switch And

Remote Receptacle

Use switch to select front panel or remote

voltage/amperage control. For remote con-

trol, place switch in Remote position and

connect remote control to Remote recep-

tacle RC4 (see Sections 5-8 and 6-4).

3 V/A Control

Use control to select weld voltage or

amperage. Control may be adjusted while

welding.

. For maximum weld output (above 220

Amps), run unit at 3600 rpm. For weld

output below 220 Amps, operate unit at

3000 or 3600 rpm.

With Process/Contactor switch in Stick or

TIG setting, use control to adjust amperage.

With Process/Contactor switch in Wire posi-

tion, use control to adjust voltage. With V/A

Adjust Switch in Remote position, control

limits the remote amperage in Stick and TIG

modes, but has no effect in MIG modes.

4 Engine Hour Meter

Use hour meter to help schedule routine

maintenance (see Section 8-1).

5 Engine Choke Control

Use control to change engine air-fuel mix

when starting engine. Pull control out when

starting a cold engine. Push control in when

engine starts.

. Do not run engine with Choke control

partially on or spark plugs will foul.

6 Engine Control Switch

Use switch to start engine, stop engine, and

select engine speed. (Use switch in com-

bination with Speed Control switch to select

engine speed.) In Run/Idle 3600/2400 RPM

position, engine runs at 2400 rpm at no weld

load, and 3600 rpm under weld load. In Run/

Idle 3000/1800 RPM position, engine runs at

1800 rpm at no weld load, and 3000 rpm

under weld load. In either position, engine

speed is determined by weld load and posi-

tion of Speed Control switch (see item 7 and

table below).

. Generator power is available at recep-

tacles RC1 and RC2 only at 1800 rpm.

If generator is not locked at 1800 rpm,

engine speed increases in response to

weld load and generator power output

stops at receptacles RC1 and RC2.

Generator power load does not affect

engine speed.

7 Speed Control Switch

Use switch to control engine auto idle func-

tion. Place switch in Generator Lock position

when not welding to lock engine speed at

1800 rpm for generator power at 60 Hz ac re-

ceptacles RC1 and RC2. (Generator power

is always available at 60-120 Hz receptacle

RC3.)

Place switch in Weld position to allow engine

speeds to be determined by position of En-

gine Control switch. The Speed Control

switch is not needed at start-up.

To Start: pull out choke and turn Engine

Control switch to Start position. Release

switch and slowly push choke in when

engine starts.

. If the engine does not start, let the

engine come to a complete stop before

attempting restart.

To Stop: turn Engine Control switch to Off

position.

Controlling Engine Speed And Weld/Generator Power Output

1800 rpm (Power Speed)

Continuous

No Load: 2400 rpm (Idle Speed)

Load: 3600 rpm (Weld Speed)

Engine Controls

Engine Speed

Generator Power

Output

Weld Output

5 kW/kVA Total From

All AC Receptacles

2.4 kW/kVA at 60-120 Hz

From AC Receptacle

RC3 Only

No Load: 1800 rpm (Idle Speed)

Load: 3000 rpm (Weld Speed)

Welding Not

Recommended

3600 rpm:

20 − 300 A

3000 rpm:

20 − 220 A

Speed Control Switch In Generator

Lock. Engine Control Switch in either

Run/Idle position.

Speed Control Switch In Weld.

Engine Control Switch in 3600/2400 RPM.

Speed Control Switch In Weld.

Engine Control Switch in 3000/1800 RPM.

5 kW/kVA Total From

All AC Receptacles At 1800 rpm.

At 3000 rpm, Output Available

Only At 2.4 kW/kVA 60-120 Hz

AC Receptacle RC3