OM-4411 Page 29

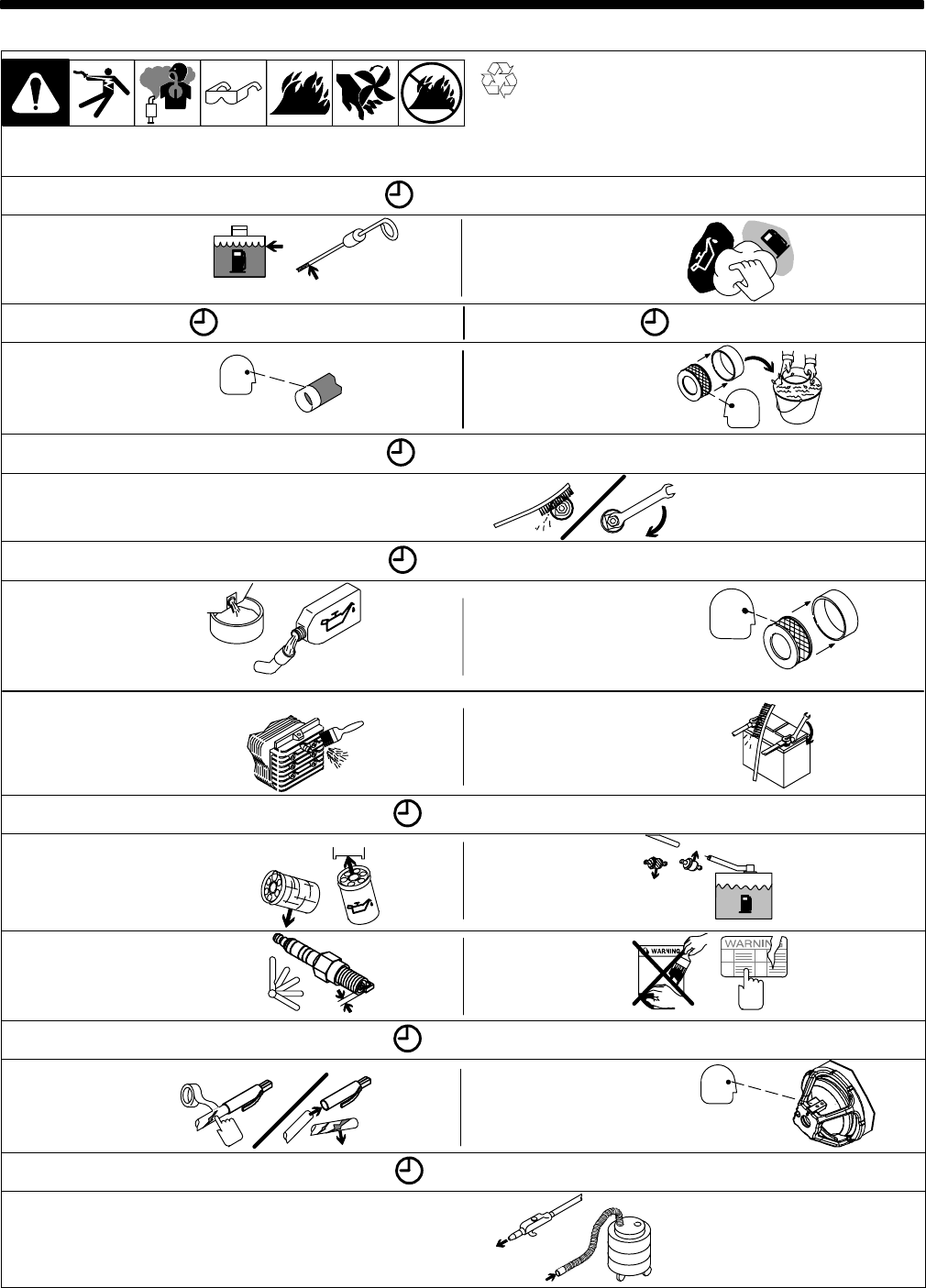

SECTION 8 − MAINTENANCE & TROUBLESHOOTING

8-1. Routine Maintenance

Recycle

engine

fluids.

Y Stop engine before maintaining.

. See Engine Manual and Maintenance Label for impor-

tant start-up, service, and storage information. Service

more often if used in severe conditions.

* To be done by Factory Authorized Service Agent.

Every 8 h

Wipe up spills.

Check fluid levels.

See Section 5-2.

OIL

Full

20 h 25 h

Check and clean

spark arrestor screen.

See Section 8-3.

Service air filter wrapper

(foam element). See

Section 8-4.

Every 50 h

Clean and tighten

weld terminals.

Every 100 h

Change oil. See

Section 8-5 and

maintenance

label.

Clean cooling system. See

engine manual.

Service air filter element.

See Section 8-4.

Clean and

tighten battery

connections.

Every 200 h

Replace fuel

filter. See

Section 8-5.

Change oil filter. See Section

8-5 and maintenance label.

Replace

unreadable

labels.

Check spark plugs, and

replace if fouled. Operation

at low speed (1800 rpm)

may increase fouling.

Every 500 h

Repair or

replace cracked

cables.

Service welding generator

brushes and slip rings.

Service more often in dirty

conditions.*

Every 1000 h

Blow out or vacuum inside. During

heavy service, clean monthly.

OR