OM-1589 Page 12

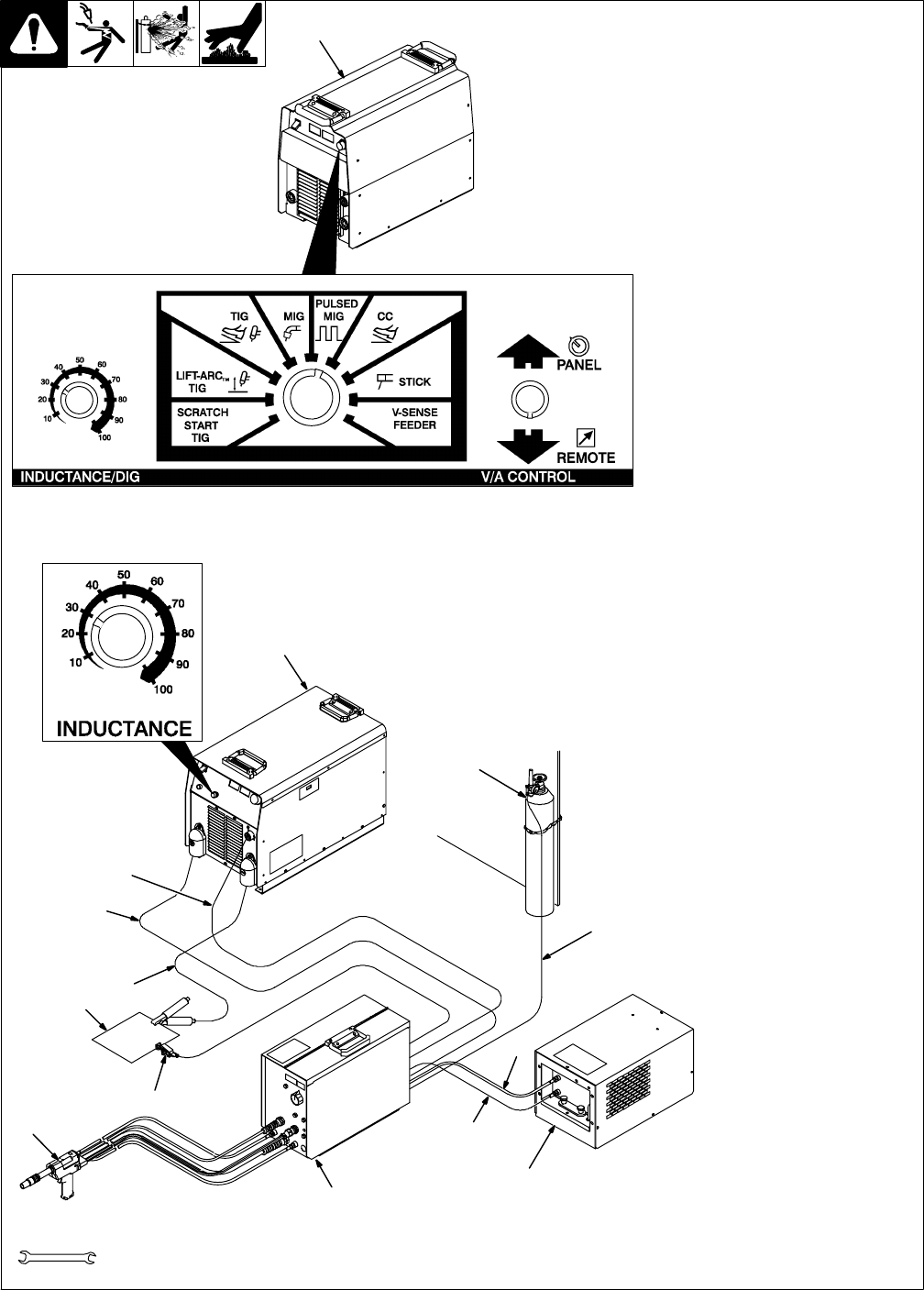

3-3. Typical Water-Cooled System Connections

801 810 / Ref. 175 086 / Ref. 180 311-B

1 300/400 Ampere Model

CC/CV Inverter Welding

Power Source

. Use settings shown for both

pulse MIG welding and MIG

welding.

2 450 Ampere Model CV

Inverter Welding Power

Source

System can be set up with a variety

of conventional Constant Voltage

(CV) welding power sources.

3 14-Pin Plug And

Interconnecting Cord

4 Positive (+) Weld Cable

5 Negative (−) Weld Cable

Select and prepare weld cables ac-

cording to welding power source

Owner’s Manual.

6 Workpiece

7 Voltage Sensing Lead

(Optional Use)

8 Water-Cooled Gun

9 Wire Feeder

10 Coolant Supply

11 Coolant In Hose

12 Coolant Out Hose

Connect hoses between coolant

supply and wire feeder.

Y Do not use gas pressure

above 50 psi (345 kPa) or me-

chanical gas valve in gun can

leak.

13 Gas Hose

14 Gas Cylinder

Route hose from regulator/flowme-

ter and connect to shielding gas

valve fitting.

Tools Needed:

9/16, 5/8, 11/16, 3/4 in

1

2

3

4

5

6

7

8

9

14

13

10

11

12