OM-492 Page 27

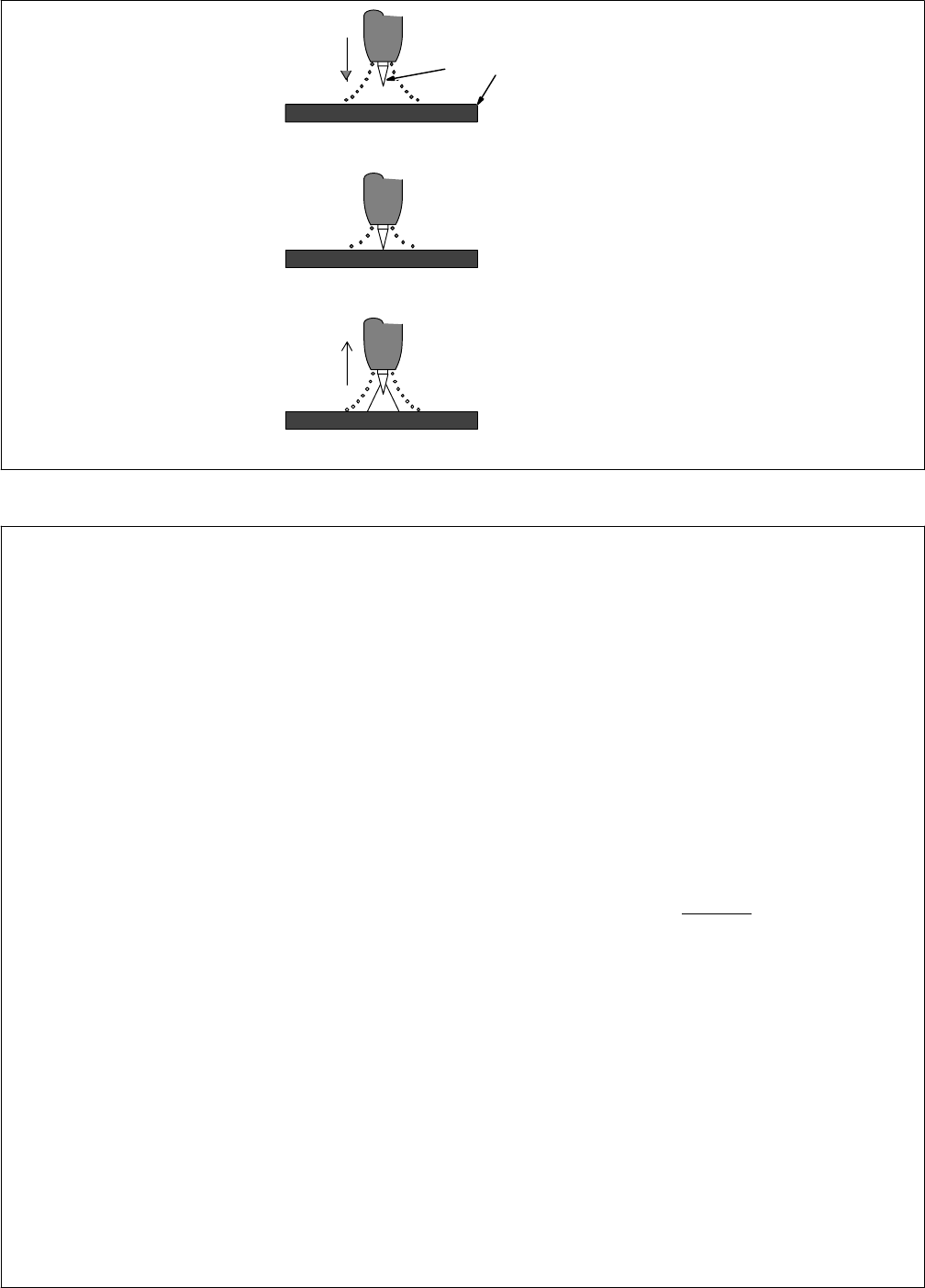

6-5. Lift-Arc TIG Procedure

With Mode Switch in the Lift-Arc

TIG position, start an arc as follows:

1 TIG Electrode

2 Workpiece

Touch tungsten electrode to work-

piece at weld start point, hold

electrode to workpiece for 1-2

seconds, and slowly lift electrode.

An arc will form when electrode is

lifted.

Normal open-circuit voltage is not

present before tungsten electrode

touches workpiece; only a low

sensing voltage is present between

electrode and workpiece. The

solid-state output contactor does

not energize until after electrode is

touching workpiece. This allows

electrode to touch workpiece with-

out overheating, sticking, or getting

contaminated.

1

1 − 2

Seconds

“Touch”

Do NOT Strike Like A Match!

2

Ref. S-156 279

6-6. Recommendations For Extreme Cold Weather Operation

. For more information on operating in cold

weather, contact the nearest Factory Au-

thorized Service Agent or Kubota Service

Center.

Fuel

D Use an arctic-grade diesel fuel and keep

fuel tank at least half full to prevent fuel

lines from draining back into tank.

D Do not use gasoline or kerosene.

D Do not use fuel additives.

Oil

D Use 10W30 oil when operating at ambient

temperatures above -4° F (−20° C).

D Use 5W30 oil when operating at ambient

temperatures above -13° F (−25° C).

D Operating at extremely low temperatures

thickens engine oil and reduces cranking

speed. Contact a Factory Authorized Ser-

vice Agent or Kubota Service Center for

information on using 0W20 oil in these

conditions. Low temperature oil must be

replaced as ambient operating tempera-

tures increase.

Coolant

D Be sure the cooling system is completely

filled with a 50/50 antifreeze/water mix

(open the radiator vent when filling). Do

not mix antifreeze and water solution in

the overflow tank. Use a premixed 50/50

antifreeze/water solution to “top off” over-

flow tank. Use caution if rerouting cooling

lines. Engine damage due to lack of

coolant or incorrect coolant mix is not

covered by the warranty.

D A 50/50 antifreeze/water mix protects en-

gine to -34°F (−37°C). If operating at even

lower temperatures, contact a Factory

Authorized Service Agent or Kubota Ser-

vice Center for coolant information.

Battery

D Replacement Battery Rating: 12 Volt, 535

CCA (minimum) 90 RSV Group 55.

D Check connections at battery, starter, and

engine block. Inspect battery cables for

abrasion and wear, and verify the battery

is secured.

D Consider installing easily-accessible bat-

tery booster leads (0 or 00 AWG) to pro-

vide easy connection to a service truck’s

battery.

D Boost the starting capability of the battery

by using a battery heater.

Starting

D Do not use ether.

D Use the engine block heater to maintain

engine temperature above ambient tem-

perature.

D Use the glow plugs for 20−30 seconds be-

fore starting. As a preseason check,

make sure the glow plugs are working

properly.

D Disconnect all unnecessary loads from

generator ac receptacles when starting.

Operating

D To reduce crankcase condensation and

breather tube freezing problems, allow

engine to reach normal operating temper-

ature as quickly as possible.

D Crankcase breather tubes will collect

condensation and freeze if the hose is im-

properly routed. The breather tube should

be free of sharp bends and kinks. A

blocked breather tube will cause exces-

sive crankcase pressure that will blow out

the safety plug, oil seals, or dipstick. Con-

tact a Factory Authorized Service Agent

to obtain a shorter breather hose that is

less likely to kink.

D Inspect the routing and condition of the

breather tube frequently. Reroute or re-

place the hose if necessary.

D For continuous use in extreme cold, block

the cooling holes in the base to reduce air

flow through the radiator and achieve

higher engine temperature. Close off the

base inlet vents only if the engine coolant

or oil temperatures can be monitored to

ensure they remain within the specified

limits.

D To obtain warmer air for combustion, turn

the air cleaner inlet away from the inlet

vents, and seal the inlet vents.

D If operating in cold weather all the time,

consider replacing the existing radiator

cooling fan with a smaller fan that draws

less air through the radiator. Operation in

warmer temperatures would require an

additional “booster” electric fan to ade-

quately cool the engine.