OM-492 Page 38

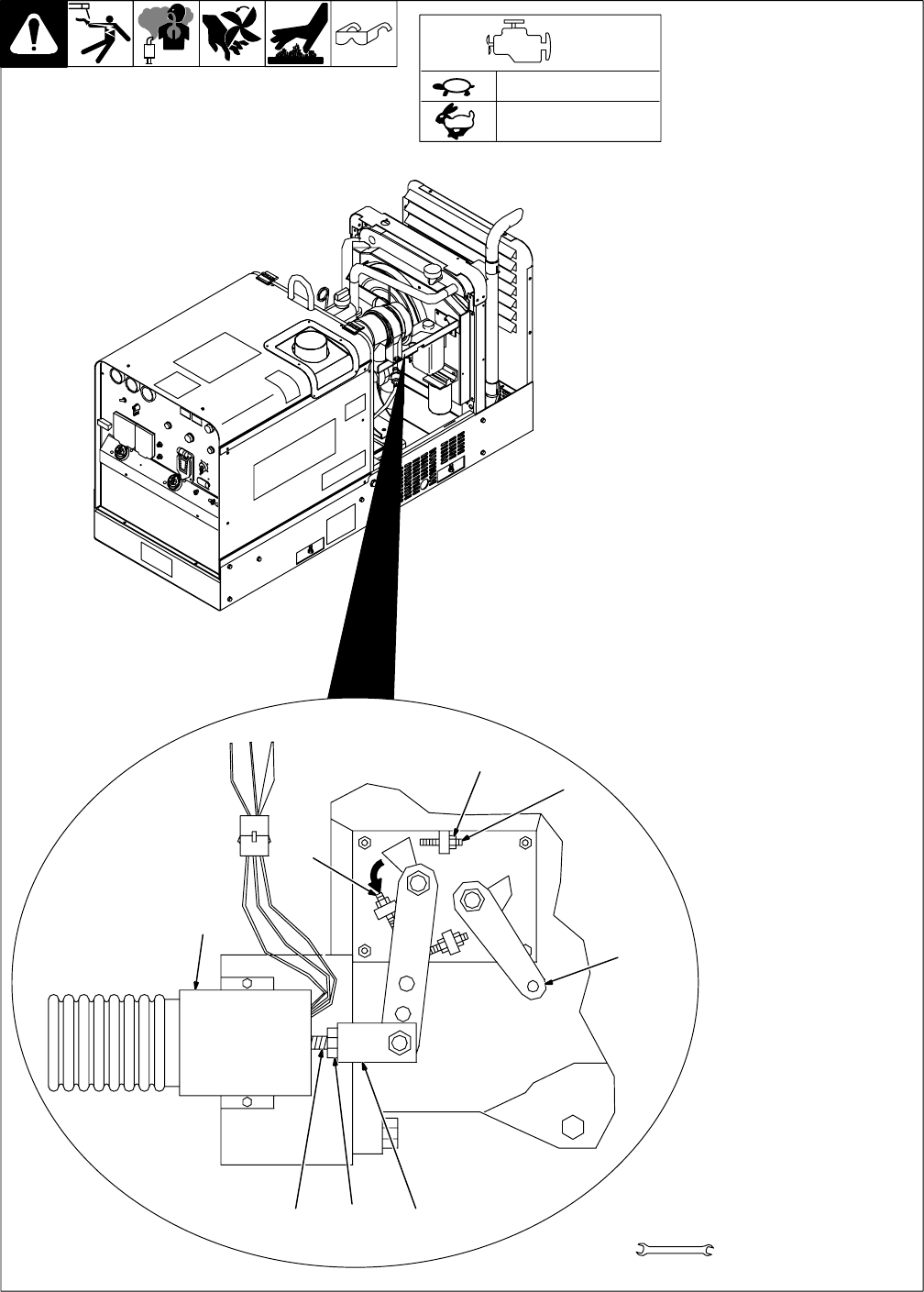

8-8. Adjusting Engine Speed

802 330-B

After tuning engine, check engine

speeds with a tachometer (see table).

If necessary, adjust speeds as follows:

Start engine and run until warm. Turn

V/A control to max.

Adjusting Idle Speed

Idle speed is factory set and normally

does not not require adjustment unless

the governor/injector pump or throttle

solenoid is replaced.

1 Throttle Link

2 Throttle Solenoid Plunger Rod

3 Jam Nut

4 Throttle Arm Stop Screw

Turn Engine Control switch to Run/Idle

position. Loosen jam nut and turn sole-

noid rod clockwise (into throttle link) to

decrease idle speed. Turn rod counter-

clockwise to increase idle speed.

Tighten nut.

. Be sure solenoid plunger rod pulls

all the way in “bottoms” when en-

ergized. If plunger rod does not

pull all the way in, readjust rod and

throttle link.

. Throttle arm should not contact

stop screw when solenoid is ener-

gized. If necessary, adjust stop

screw to create gap between

throttle arm and stop screw.

Adjusting Weld/Power Speed

5 Throttle Solenoid

6 Weld Speed Jam Nut

7 Adjustment Screw

Turn Engine Control switch to Run

position. Loosen nut and turn screw

counterclockwise to increase speed.

Turn screw clockwise to decrease

speed. Tighten nut.

Using Engine Stop Lever

8 Engine Stop Lever

Use lever to stop engine if Engine Con-

trol switch does not work.

2500 rpm (41.6 Hz)

3750 Max (62.5 Hz)

8

5

6

7

10 mm

Tools Needed:

312

4