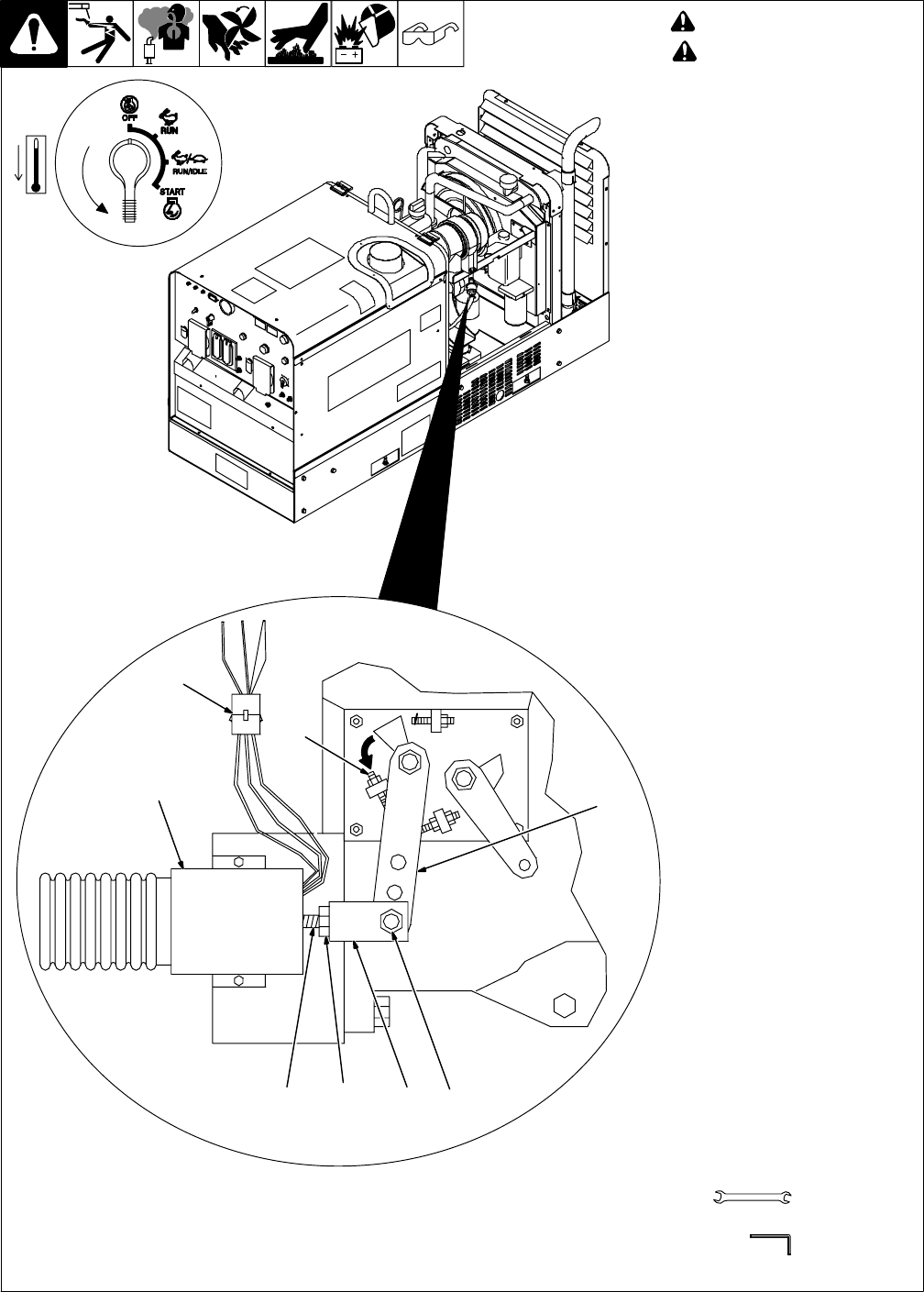

OM-492 Page 37

8-7. Replacing Throttle Solenoid TS1

802 330-B

! Stop engine, and let cool.

! Disconnect battery, negative

(−) cable first.

Remove right side engine panel.

1 Plug PLG39/Receptacle RC39

2 Throttle Solenoid TS1

3 Shoulder Bolt And Nut

4 Throttle Link

5 Throttle Solenoid Plunger Rod

6 Jam Nut

7 Throttle Arm

8 Throttle Arm Stop Screw

Disconnect solenoid plug PLG39

from wiring harness receptacle

RC39.

Remove shoulder bolt and nut from

throttle link.

Remove solenoid from mounting

bracket.

Note how much thread is visible on

solenoid plunger rod. Loosen jam nut

just enough so throttle link can be re-

moved from solenoid rod.

Install throttle link on new solenoid

plunger rod. Turn link until the same

amount of thread will be visible on

plunger rod when the jam nut is tight-

ened. (Do not tighten jam nut yet.)

Mount solenoid on bracket. Move so-

lenoid plunger manually to align slot

in throttle link with hole in throttle arm.

Insert shoulder bolt through slot/hole

and secure with nut.

. Be sure solenoid plunger rod

pulls all the way in “bottoms”

when energized. If plunger rod

does not pull all the way in, re-

adjust throttle link.

. Throttle arm should not contact

stop screw when solenoid is en-

ergized. If necessary, adjust

stop screw to create gap be-

tween throttle arm and stop

screw.

Tighten jam nut on solenoid plunger

rod. Verify all other hardware is tight.

Connect solenoid plug PLG39 to wir-

ing harness receptacle RC39.

Reconnect battery, negative (−) lead

last.

Check engine speeds and adjust if

necessary according to Section 8-8.

Reinstall side panel.

10 mm

Tools Needed:

7/16, 3/8, 1/2 in

7

2

6 345

3/16 in

1

8