OM-492 Page 42

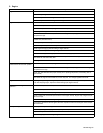

Trouble Remedy

Remote contactor control does not

activate contactor.

Check and tighten connections to Remote 14 receptacle RC14 (see Section 5-8).

Lack of high frequency; difficulty in

establishing Gas Tungsten Arc Weld-

ing arc.

Use proper size tungsten for welding amperage.

Reduce leakage of high frequency from torch or work cable (check grounding, remove excessive

coils from weld cables, use shorter weld cables, etc.).

Check cables and torch for cracked or deteriorated insulation or bad connections. Repair or replace

necessary parts.

Wandering arc − poor control of arc

direction.

Reduce gas flow rate.

Select proper size tungsten. Properly prepare tungsten.

Tungsten electrode oxidizing and not

remaining bright after conclusion of

weld.

Shield weld zone from drafts.

Increase postflow time.

Check and tighten all gas fittings.

Properly prepare tungsten.

No 115 volt ac output at Remote 14 re-

ceptacle RC14.

Reset supplementary protector CB5 (see Section 8-9).

No 24 volt ac output at Remote 14 re-

ceptacle RC14.

Reset supplementary protector CB6 (see Section 8-9).

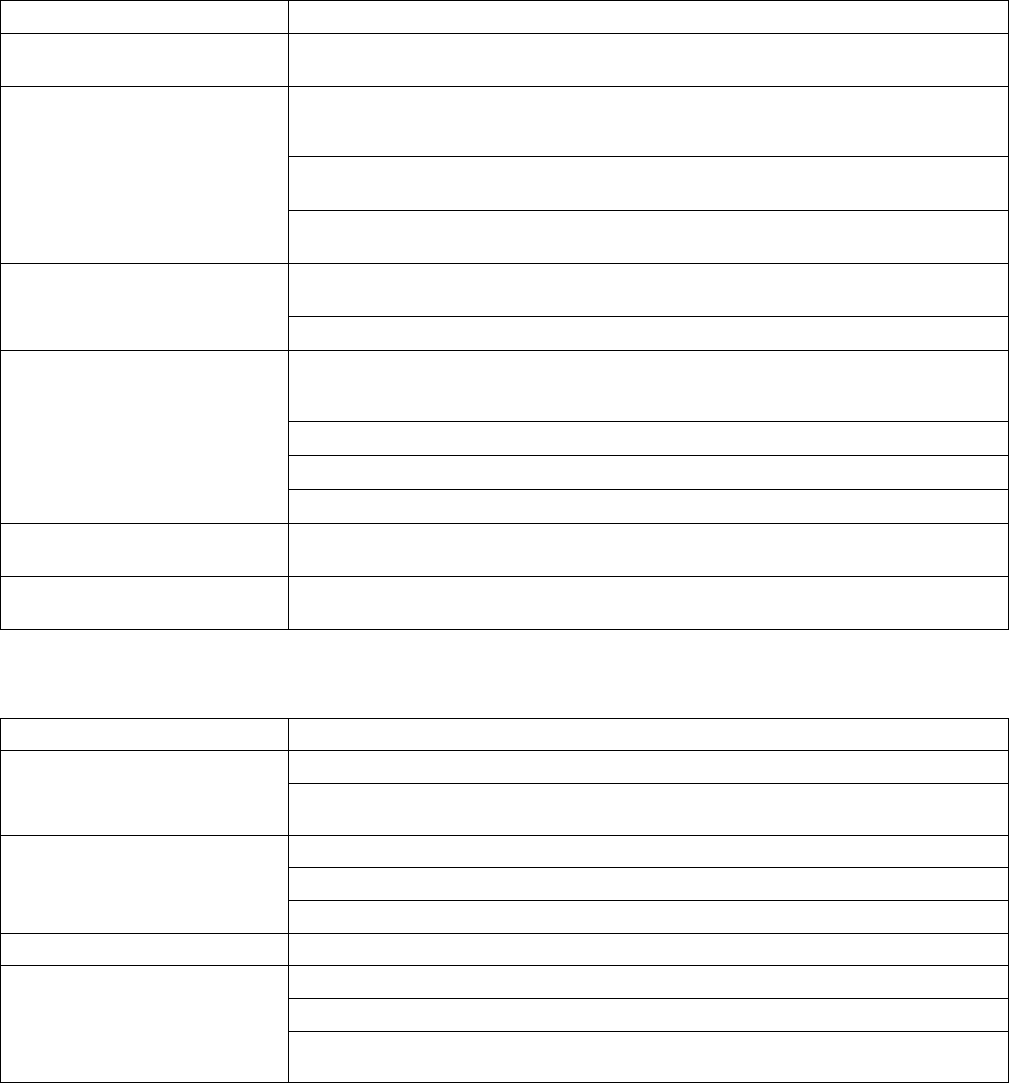

B. Generator Power

Trouble Remedy

No power output. Reset supplementary protectors (see Section 7-1).

Have Factory Authorized Service Agent check brushes, slip rings, power board PC7, voltage regulator

board PC8, interconnecting board PC2, and control board PC1.

Low power output. Check air cleaner, and clean or replace element if necessary.

Check engine speed, and adjust if necessary (see Section 8-8).

See engine manual.

High power output. Check engine speed, and adjust if necessary (see Section 8-8).

Erratic power output. Check receptacle wiring and connections.

Check governor according to engine manual.

Have Factory Authorized Service Agent check brushes, slip rings, power board PC7, voltage regulator

board PC8, interconnecting board PC2, and control board PC1.