OM-217 Page 20

SECTION 4 – OPERATION

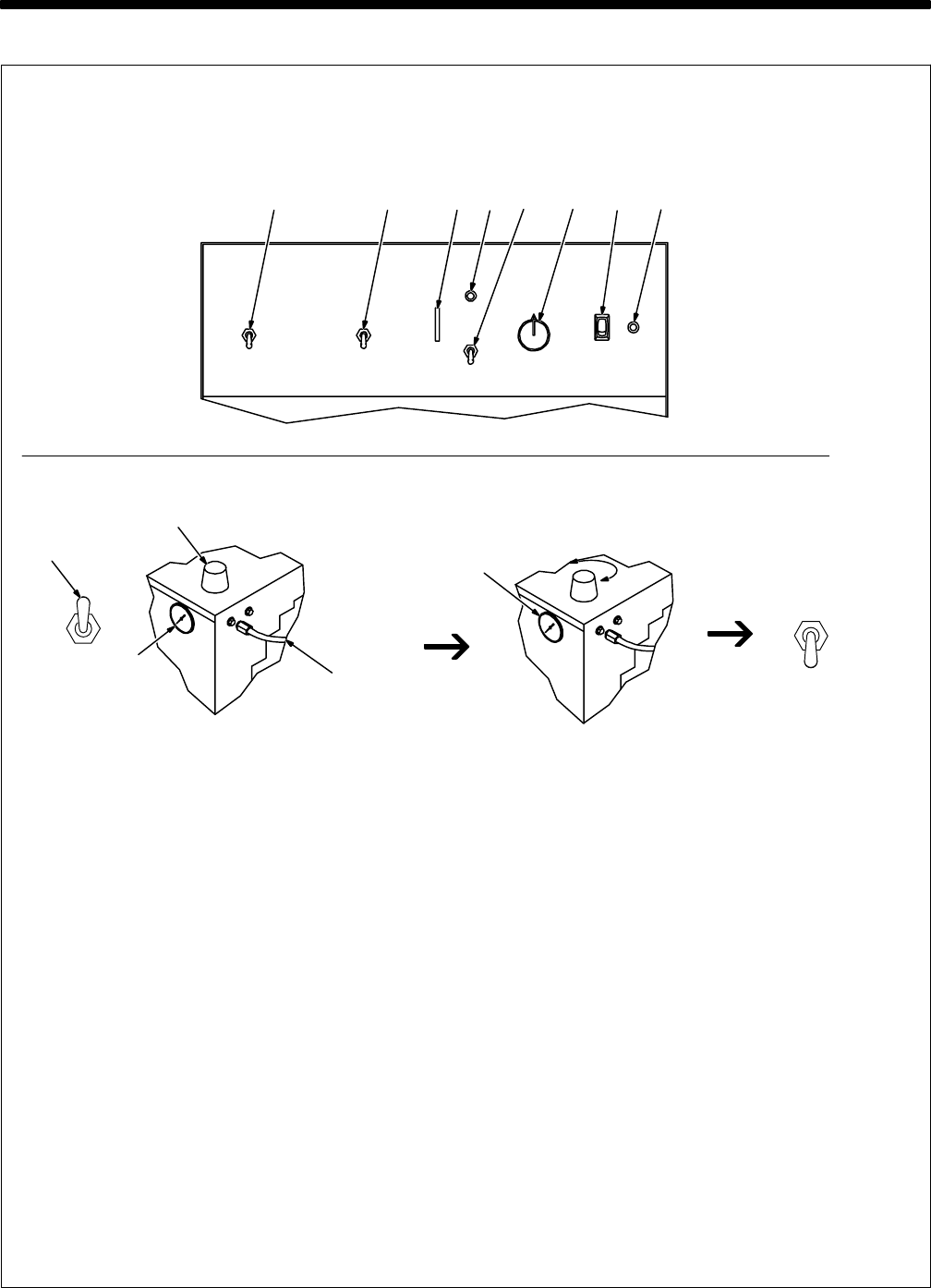

4-1. Controls

Ref. ST-159 465-A / ST-800 701 / S-0818

12345678

1 Pilot Light

2 Power Switch

3 Output Control

Use control to set cutting output.

For non-shielded cutting, use a 1/8 in (3 mm)

standoff distance between torch tip and

workpiece.

4 Set/Run Switch

Place switch up to safely adjust gas/air pres-

sure. Only gas/air circuit is activated.

Place switch down to cut or gouge.

5 Ready Light

Use light to tell if unit is ready for operation.

Ready light comes on when Power switch is

placed in On position, indicating that all safe-

ty shutdown systems are okay.

If Ready light does not come on, check

Trouble Lights.

6 Trouble Lights (See Section 5-3)

7 Trigger Hold Switch

To cut without holding torch trigger, place

switch up, and begin cutting by pressing and

releasing torch trigger. To stop cutting, press

and release trigger.

When set in down position, trigger must be

held closed while cutting.

8 Pilot Arc Control Switch

Place switch down for pulsed pilot arc

output. Use this position whenever possible

to reduce wear on torch and consumables.

Place switch up for a continuous pilot arc.

Use this position when cutting starts are

critical or while cutting expanded metals.

Setting Gas/Air Pressure

9 Air Filter/Regulator

10 Pressure Adjustment Knob

Place Set/Run switch up and turn on gas/air

supply. Lift knob and turn to adjust pressure.

Push knob down to lock in setting.

Place Set/Run switch down to begin cutting.

Requires

80-150 psi

(552-1034 kPa)

Supply

9

10

Setting Gas/Air Pressure

4

Set To 70 psi

(482 kPa)