OM-217 Page 24

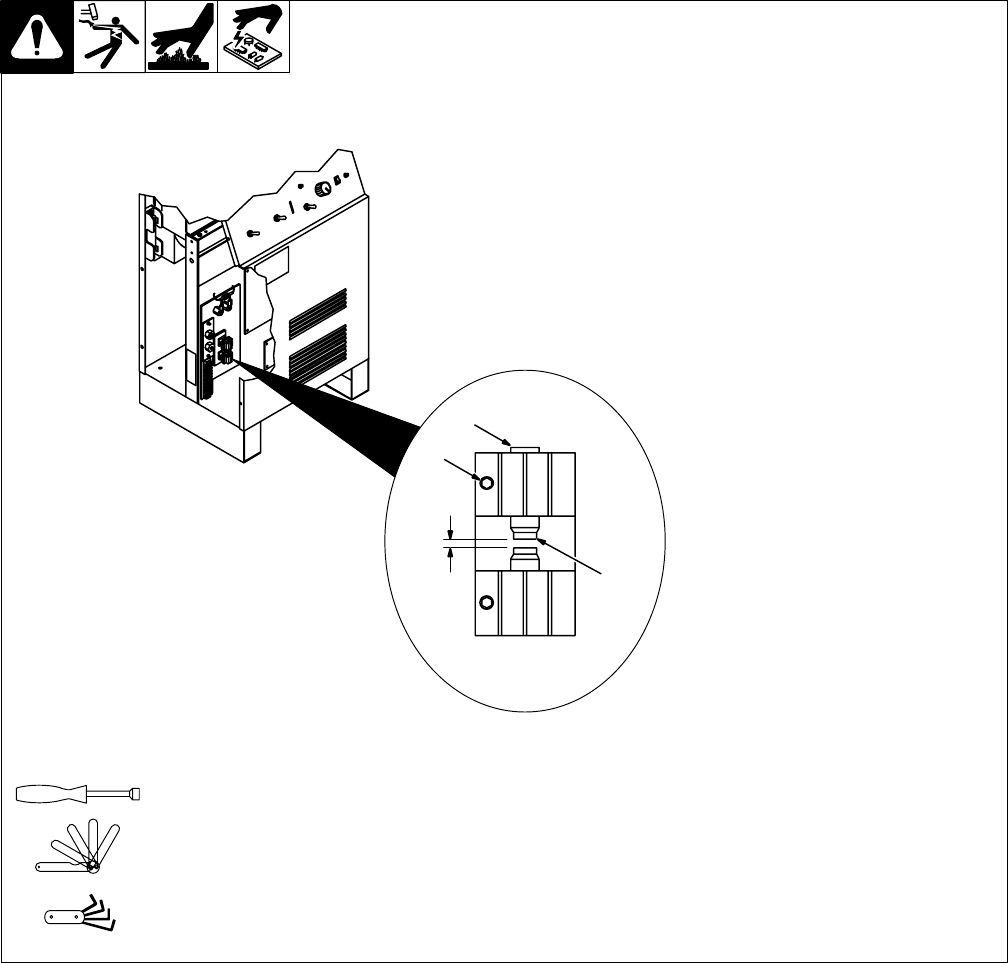

5-4. Adjusting Spark Gap

Y Turn Off power before ad-

justing spark gap.

Remove left side panel.

1 Tungsten End Of Point

Replace point if tungsten end dis-

appears; do not clean or dress

tungsten.

2 Spark Gap

Normal spark gap is 0.030 in (0.762

mm).

If adjustment is needed, proceed as

follows:

3 Adjustment Screw

Loosen screw. Place gauge of

proper thickness in spark gap.

4 Pressure Point

Apply slight pressure at point until

gauge is held firmly in gap. Tighten

screw.

Reinstall side panel.

Ref. ST-159 466-C / S-0201

2

3

4

1

Tools Needed:

3/8 in

5/32 in

0.030 in (0.762 mm)