. A complete Parts List is available at www.MillerWelds.com

OM-201 872 Page 35

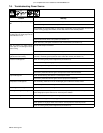

80 Amp Machine Torch Extended Consumables

The following cut charts are based on a distance of 3/16 in (4.8 mm) between torch tip and workpiece for all cuts.

212 734212 724212 728212 733212 736

Swirl RingElectrodeTipRetaining CapDeflector

ICE-100TM Torch

Mild Steel

Arc Current

Arc Voltage

Pierce

Delay

Material Thickness Maximum Cut Speeds Optimum Cut Speeds

Arc Current

Arc Voltage

Pierce

Delay

Inches mm IPM mm/min IPM mm/min

80 138 0.25 3/16 4.7 221 5,613 142 3,607

80 140 0.5 1/4 6.4 170 4,318 110 2,794

80 143 0.5 3/8 9.5 98 2,489 63 1,600

80 146 0.5 1/2 12.7 62 1,574 42 1,067

80 149 1 5/8 15.8 42 1,066 28 711

Stainless

Arc Current

Arc Voltage

Pierce

Delay

Material Thickness Maximum Cut Speeds Optimum Cut Speeds

Arc Current

Arc Voltage

Pierce

Delay

Inches mm IPM mm/min IPM mm/min

80

138 0.5 1/4 6.4 160 4,064 106 2,692

80

143 1 1/2 12.7 55 1,397 34 863

Aluminum

Arc Current

Arc Voltage

Pierce

Delay

Material Thickness Maximum Cut Speeds Optimum Cut Speeds

Arc Current

Arc Voltage

Pierce

Delay

Inches mm IPM mm/min IPM mm/min

80 140 0.25 1/4 6.4 140 3,556 120 3,048

80 147 1 1/2 12.7 80 2,032 42 1,067

Without concern for cut appearance, the fastest speed for cutting material is the maximum cut speed. For better cut angle, less dross, and cut surface

appearance, use the optimum cut speed. The values in the cut charts are basic starting points and each application may require some adjustment to

achieve the best cut characteristics.