OM-4407 Page 23

SECTION 6 − OPERATING WELDING GENERATOR

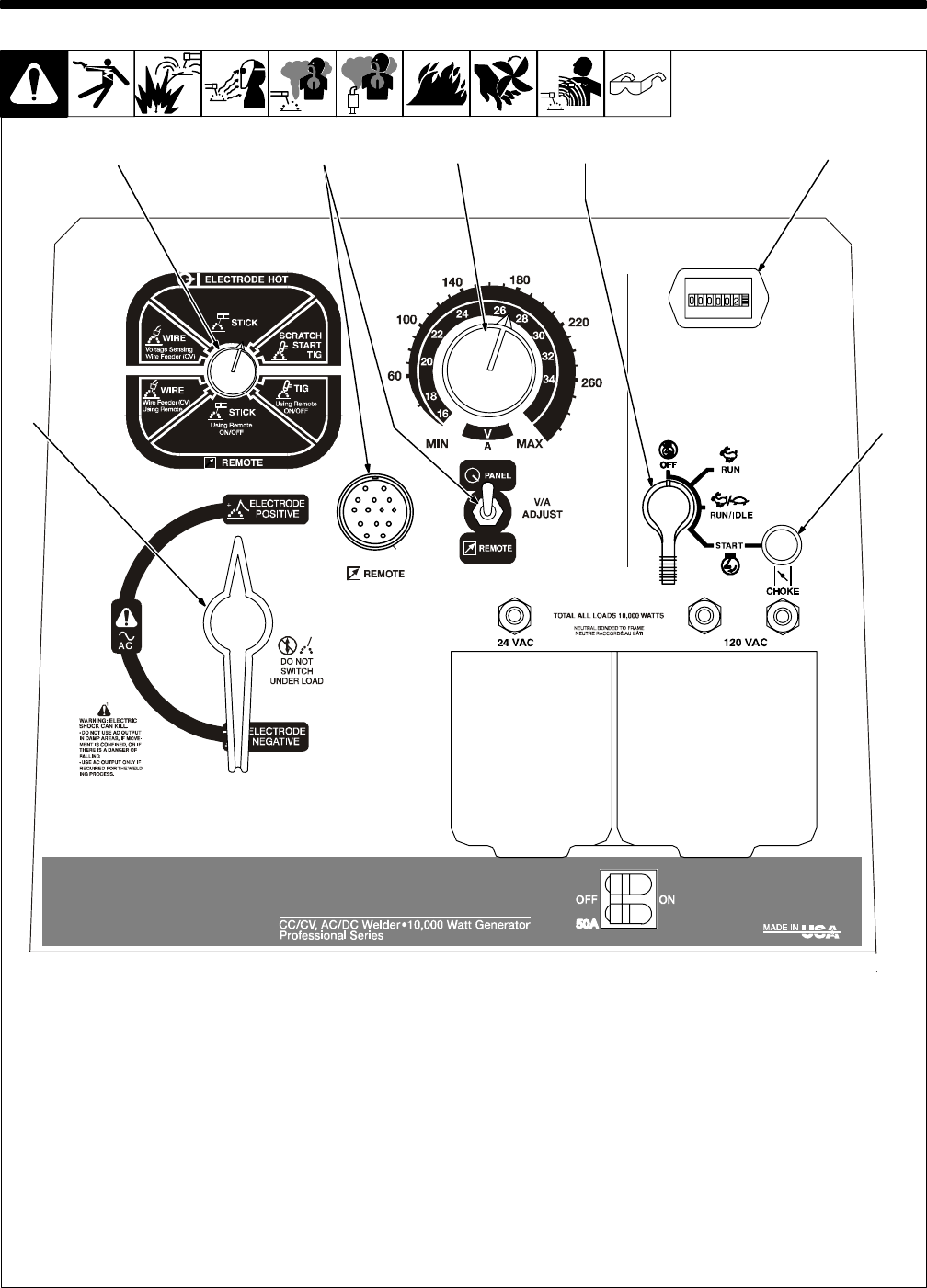

6-1. Front Panel Controls

1 Process/Contactor Switch

See Section 6-2 for Process/Contactor

switch information.

2 Voltage/Amperage Adjust Switch And

Remote Receptacle

Use switch to select front panel or remote

voltage/amperage control. For remote con-

trol, place switch in Remote position and

connect remote control to Remote recep-

tacle RC4 (see Sections 5-9 and 6-3).

3 A/V Control

Use control to select weld voltage or

amperage. Control may be adjusted while

welding.

With Process/Contactor switch in any Stick

or TIG setting, use control to adjust amper-

age. With Process/Contactor switch in any

Wire position, use control to adjust voltage.

With V/A Adjust Switch in Remote position,

control limits the remote amperage in Stick

and TIG modes, but has no effect in MIG

modes.

4 Engine Control Switch

Use switch to start engine, select speed, and

stop engine. In Run/Idle position, engine

runs at idle speed at no load, and weld/power

speed under load. In Run position, engine

runs at weld/power speed.

. Place switch in Run position for TIG

(GTAW) welding using a high frequency

device.

. The unit will not return to idle speed

when the remote contactor is on.

5 Engine Choke Control

Use control to change engine air-fuel mix

when starting engine.

To Start: pull out choke and turn Engine

Control switch to Start position. Release

switch and slowly push choke in when

engine starts.

. If the engine does not start, let the

engine come to a complete stop before

attempting restart.

To Stop: turn Engine Control switch to Off

position.

6 Engine Hour Meter

7 DC Polarity/AC Switch (AC/DC Models

Only)

Y Do not switch under load.

Use switch to select AC weld output or polar-

ity of DC weld output.

421

5

63

7

Ref. 206 422