OM-4407 Page 44

Trouble Remedy

Engine does not start. Check fuel level (see Section 5-2 or 5-3).

Check battery and replace if necessary.

Check engine charging system according to engine manual.

Have Factory Authorized Service Agent check fuel shutoff solenoid GS1 according to engine manual

(GS1 standard on Kohler-powered units; optional on Robin-powered, LP-fueled units).

See engine manual.

Engine starts but stops when Engine

Control switch returns to Run/Idle

position.

Check oil level (see Section 5-2 or 5-3). Low oil pressure shutdown stops engine if oil pressure is too

low.

Use correct grade oil for operating temperature. (see Section 8-1 or 9-2).

Have Factory Authorized Service Agent check low oil pressure shutdown switch S5.

Battery discharges between uses. Place Engine Control switch in Off position when unit is not running.

Clean top of battery with baking soda and water solution; rinse with clear water.

Periodically recharge battery (approximately every 3 months).

Replace battery.

Check voltage regulator according to engine manual.

Engine stopped during normal

operation.

Check fuel level (see Section 5-2 or 5-3).

Check oil level (see Section 5-2 or 5-3). Low oil pressure shutdown stops engine if oil pressure is too

low.

Have Factory Authorized Service Agent check fuel shutoff solenoid GS1 according to engine manual

(GS1 standard on Kohler-powered units; optional on Robin-powered, LP-fueled units).

Have Factory Authorized Service Agent check low oil pressure shutdown switch S5.

Engine does not return to idle speed. Be sure Engine Control switch S2 is in Run/Idle position.

Remove all weld and generator power loads.

Place Process/Contactor switch in Electrode Hot position or turn off remote contactor. The unit will not

return to idle speed when Process/Contactor switch is in a remote position and the remote contactor

is on.

Turn off remote device connected to Remote receptacle RC4 (see Section 5-9).

Check for obstructed movement of solenoid linkage (see Section 8-7 or 9-6).

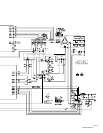

Have Factory Authorized Service Agent check circuit board PC1 and current transformer CT1.

Engine does not remain at weld/power

speed when power or weld load is

applied with Engine Control switch in

Run/Idle position.

Place Engine Control switch in the Run position for small loads.

Check for obstructed movement of solenoid linkage (see Section 8-7 or 9-6).