23

CONSTRUCTING A FEATHERBOARD

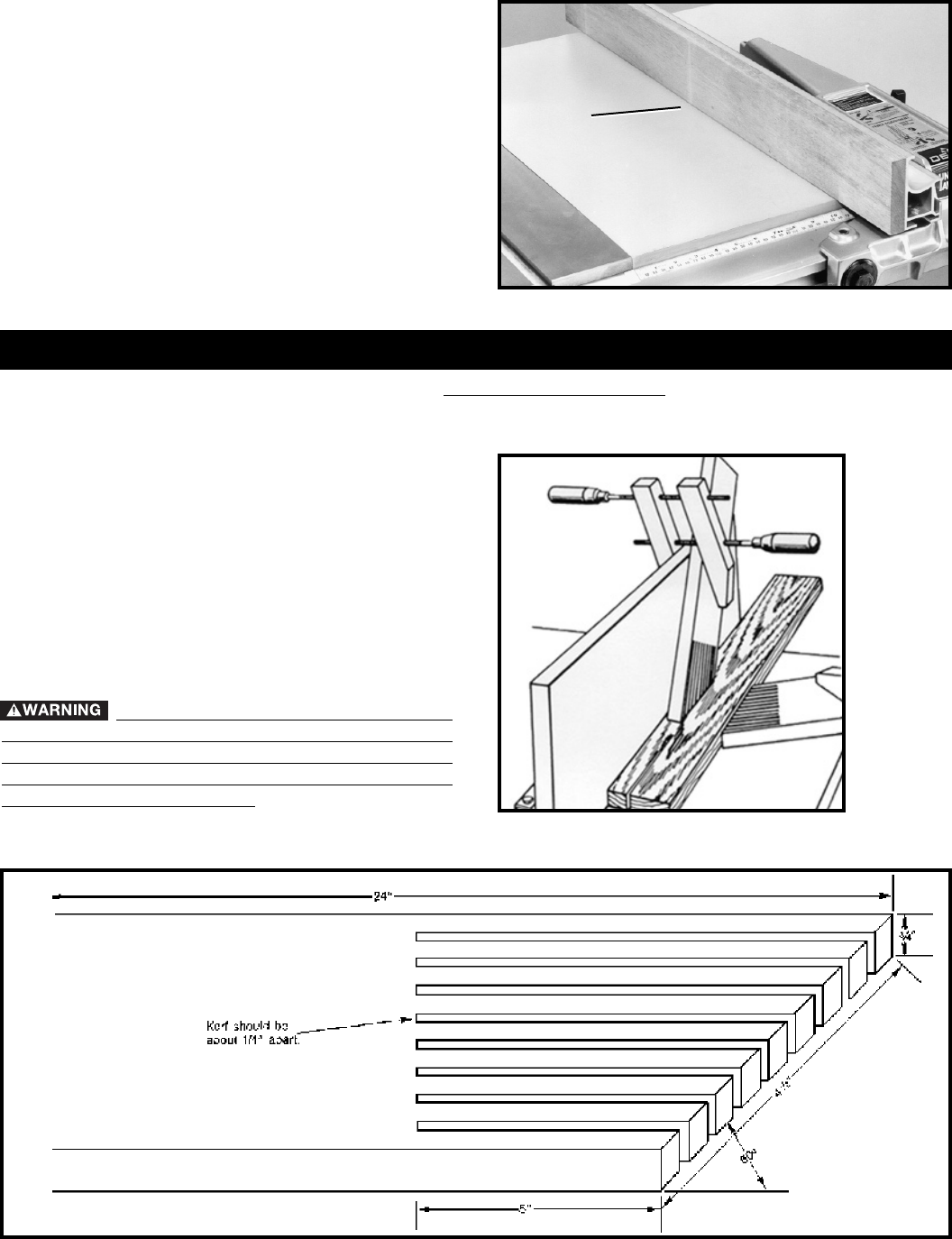

Fig. 73, illustrates dimensions for making a typical

featherboard. The material which the featherboard is

constructed of, should be a straight piece of wood that

is free of knots and cracks. Featherboards are used to

keep the work in contact with the fence and table and

help prevent kickbacks. Clamp the featherboards to the

fence and table so that the leading edge of the

featherboards will support the workpiece until the cut is

completed.

Use featherboar

ds for all non “thru-

sawing” operations where the guard and spreader

assembly must be removed (see Fig. 72). Always replace

the guard and spreader assembly when the non thru-

sawing operation is completed.

Fig. 72

Fig. 73

USING AUXILIARY WOOD FACING ON RIP FENCE

Fig. 71

A

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call

the DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

When performing special cutting operations – and that

operation may cause the cutting implement to contact

the fence – it is necessary to add a wood facing (A) Fig.

71, to one side of the rip fence as shown. The wood

facing is attached to the fence with wood screws

through holes drilled in the fence. 3/4-inch stock is

suitable for most work, although an occasional job may

require one-inch facing.