16

Maintenance

Before doing maintenance on

the machine, disconnect it from the electrical

supply by pulling out the plug or switching

off the main switch! Failure to comply may

cause serious injury.

After each use, clean sawdust from the table

with a brush (do not use your hands).

Occasionally apply a light film of oil to the quill

and column. This will reduce wear, prevent rust

and assure ease of operation.

Apply grease to the rack on the column.

Check that bolts are tight and electrical cords

are in good condition. Belts should be in good

condition and tensioned properly. Occasional

dressing of the belts with spray can type belt

dressing or paraffin wax will promote longer belt

life and quieter operation.

Bearings on the drill press are self-contained

and permanently lubricated; no further

lubrication is needed.

Exposed metal surfaces of the table and base

should be kept clean and free of rust. Apply a

good quality paste wax. Avoid any wax that

contains silicone or other synthetic ingredients.

These materials can find their way into lumber

and can make staining and finishing difficult.

The quill return spring should receive SAE 20 oil

once yearly. Apply the oil beneath the coil spring

cover (E, Figure 19) using a squirt can.

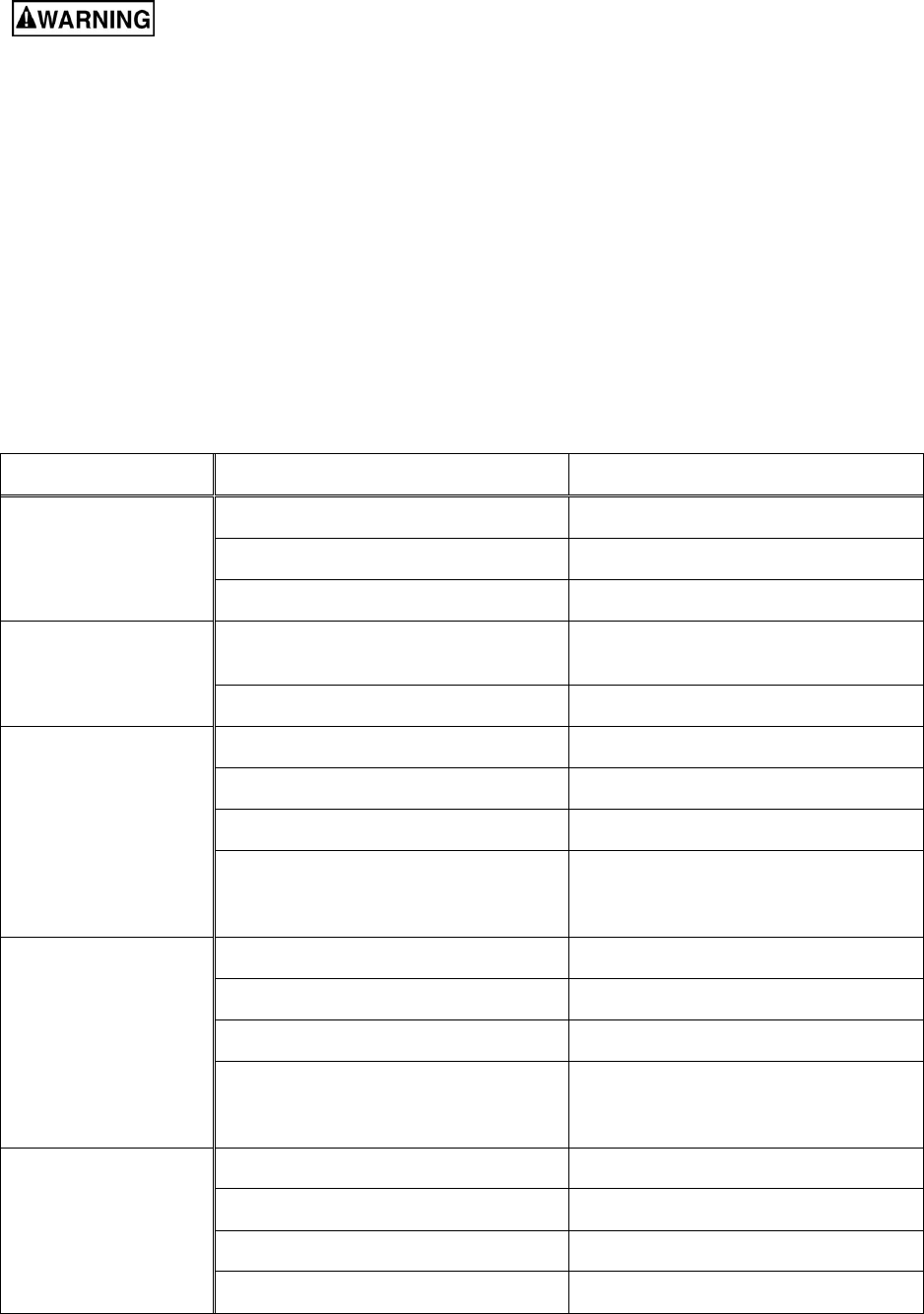

Troubleshooting

Trouble Probable Cause Remedy

Not connected to power. Check all plug connections.

Fuse blown, or circuit breaker tripped. Replace fuse, or reset circuit breaker.

Drill press will not

start.

Cord damaged. Replace cord.

Extension cord too light or too long.

Replace with adequate size and

length cord.

Drill press does not

come up to speed.

Low current. Contact a qualified electrician.

Improper belt tension. Adjust belt tension.

Uneven belt wear (hard spots). Replace belt.

Motor or spindle pulley out of balance. Balance or repair problem pulley.

Excessive vibration.

Motor malfunction.

Have motor tested by a qualified

service center. Repair or replace as

necessary.

Overfeeding the bit. Reduce feed rate.

Dull bit. Sharpen or replace bit.

Motor not reaching running speed. Repair or replace motor.

Motor stalls.

Motor is malfunctioning.

Have motor tested by a qualified

service center. Repair or replace as

necessary.

Excessive vibration. See “Excessive Vibration” above.

Incorrect belt tension. Adjust belt tension.

Dry spindle. Lubricate spindle.

;Noisy Operation.

Loose pulleys. Make any needed corrections.