8

Assembly

Tools required for assembly:

Cross-point (Phillips) screwdriver

Rubber mallet

Wrenches – 17, 18 and 24 mm

Set of hex (Allen) wrenches

Exposed metal surfaces on the drill press have

been factory-coated with a protectant. Remove

this with a soft rag moistened with kerosene or a

light solvent. Do not use an abrasive pad and do

not use gasoline, paint thinner or acetone, as

these will damage plastic components and

painted surfaces.

The drill press should be placed in a dry area

with a level floor and good lighting. Provide

enough space around the drill press to allow for

operations and any adjustments or servicing.

Assembly is a two person

operation to avoid injury from accidental

dropping.

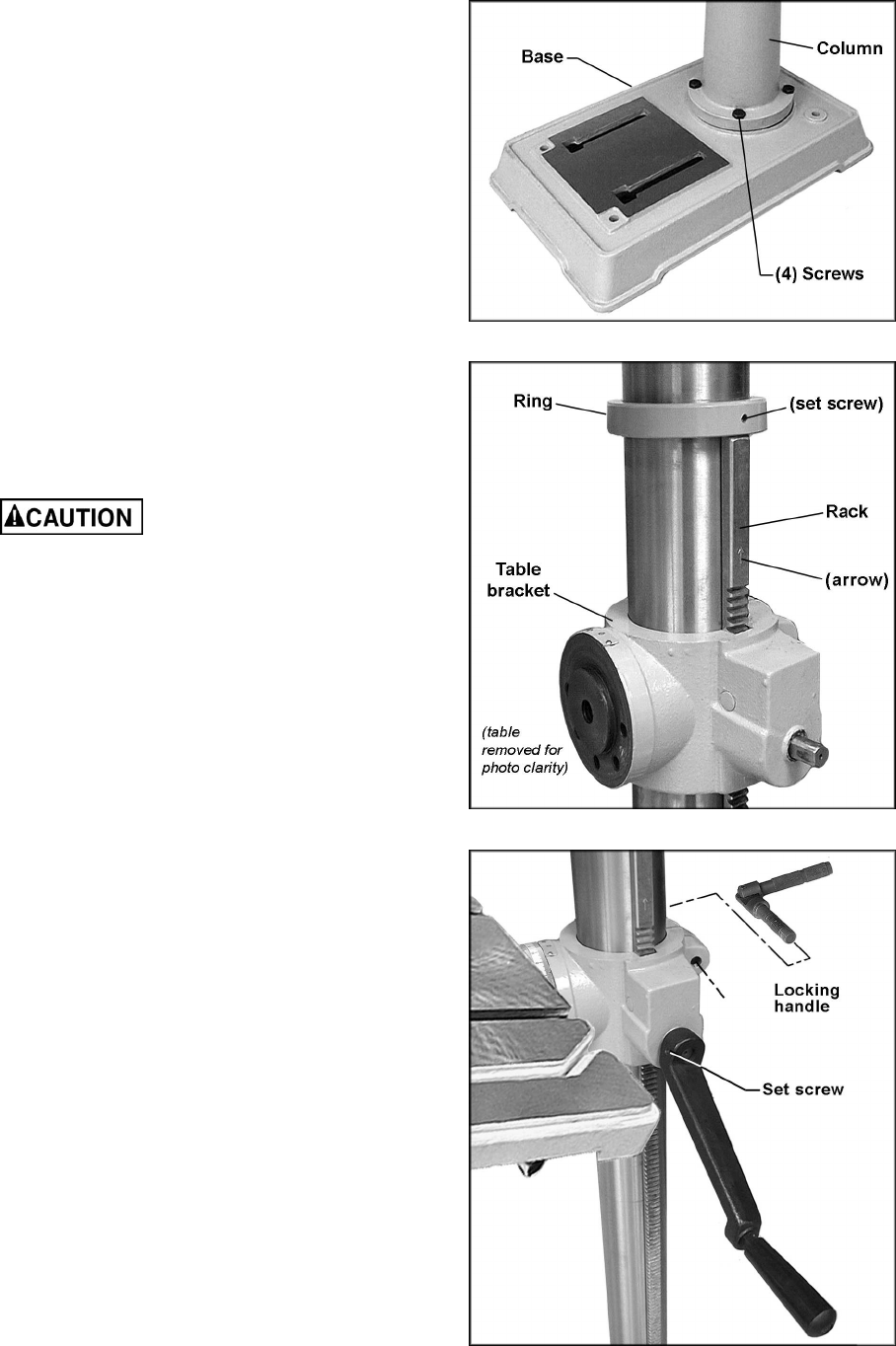

Column

1. Place the base (Figure 2) upon a level floor.

It may be secured to the floor with lag

screws (not provided) through the four holes

in the base.

2. If you do not wish to permanently secure the

drill press to the floor, it should be bolted to

a plywood panel which will serve as its

base. Use a high grade of plywood at least

3/4" thick. It should be large enough to

prevent vibration, sliding or moving of the

drill press during operation. Do not use a

mobile base with this machine.

3. Attach the column assembly (Figure 2) to

the base with four M10x40 hex cap screws.

Table Bracket

1. Remove the ring from the column by

loosening the set screw and sliding the ring

off. Also remove the rack. See Figure 3.

2. Set the table bracket (attached to the table)

over the column while sliding the rack down

through the slot in the table bracket and

against the column (Figure 3). The lower

end of the rack should rest in the lip of the

holder, as shown in Figure 5. Make sure

the rack is oriented properly; the long flat

section should be toward the top and the

short flat section toward the bottom. (The

arrow inscribed on the rack should point

upward, as shown in Figure 3.)

Figure 2

Figure 3

Figure 4