18

Drive Belt Tension

The tightness of the belt that drives the spindle

has been adjusted at the factory. Further

adjustment may be necessary after the machine

receives some use, as the belt may stretch

slightly during the “breaking in” process.

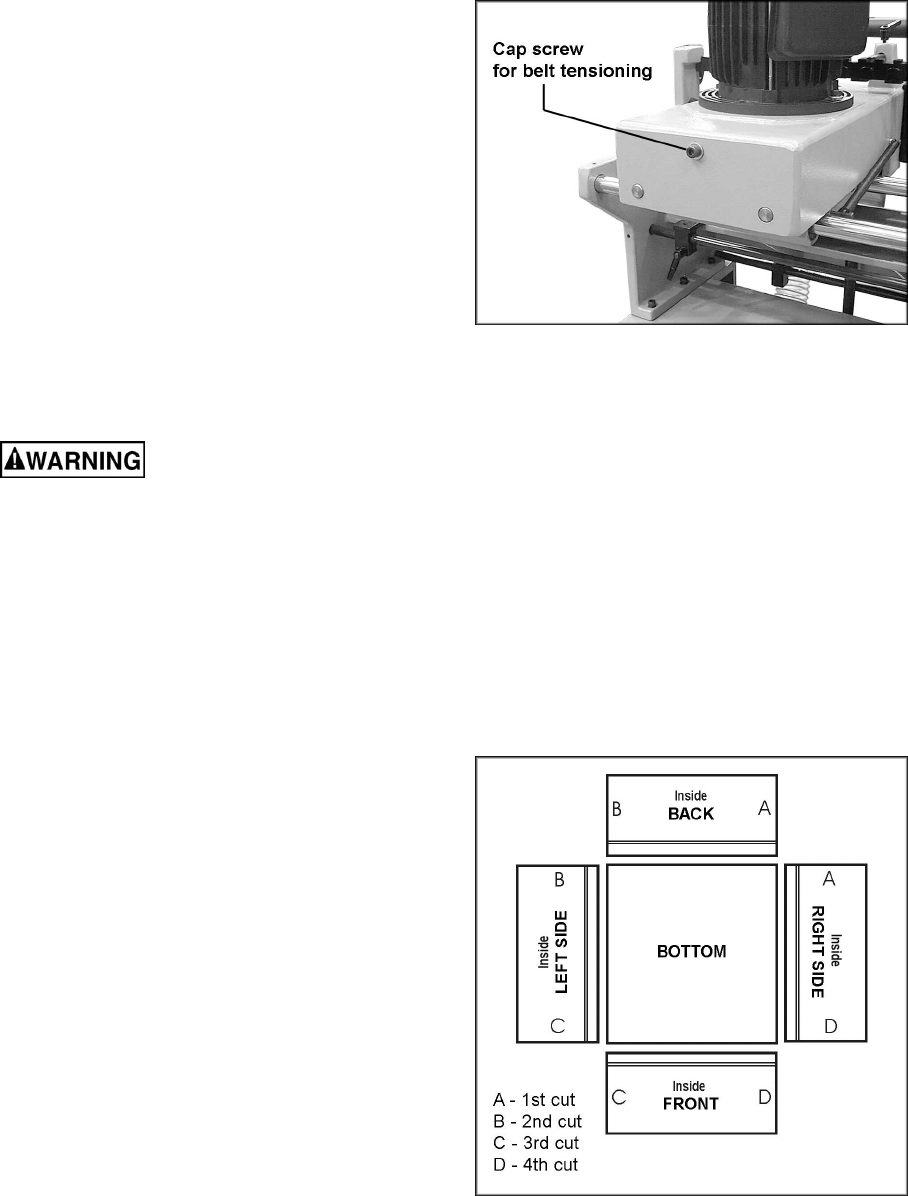

Belt tension can be adjusted by a socket head

cap screw at the rear of the headstock (Figure

24) which slides the motor toward or away from

the spindle. To tighten the belt, rotate this cap

screw clockwise with a 6mm hex wrench. To

loosen the belt, rotate the cap screw

counterclockwise. The belt should be just tight

enough to prevent it slipping on the spindle

during operation.

Replacing Cutter

The cutter is very sharp; use

caution when working with or around cutter.

Disconnect machine from power source!

Failure to comply may cause serious injury.

To replace the cutter, loosen both set screws

(Figure 23) and carefully pull down on the cutter

until it is free from the spindle. Place the new

cutter in the spindle and tighten both set screws.

Operation

NOTE: The following are basic dovetailing

procedures as they apply to this machine, and

are not intended to be a full course of instruction

in making dovetails. Refer back to the

terminology on page 7 if needed.

The Dovetailer can be used to make joints in

drawers, boxes, cabinets, etc. Instructions in this

manual are based upon making a drawer

consisting of FRONT and BACK pieces, and two

SIDE pieces. FRONT and BACK pieces are

placed horizontally on top the machine’s table;

SIDE pieces are placed vertically in front of the

machine’s table. The insides of the boards

always face outward when they are placed on

the machine.

No matter the project, prevent mistakes by

laying out the pieces beforehand according to

how they will be assembled. Place them with the

inside facing up, and label the mating edges, as

shown in Figure 25.

Before cutting on what is to be the finished

piece, the operator should make test cuts on

scrap wood to make sure all settings and

adjustments are correct.

Figure 24

Figure 25