9

Installation & Assembly

Tools required for assembly

forklift or hoist with straps/slings

11mm wrench (provided)

[NOTE: A socket set with ratchet wrench may

speed assembly]

4 and 5mm hex wrenches (provided)

knife or wire cutter

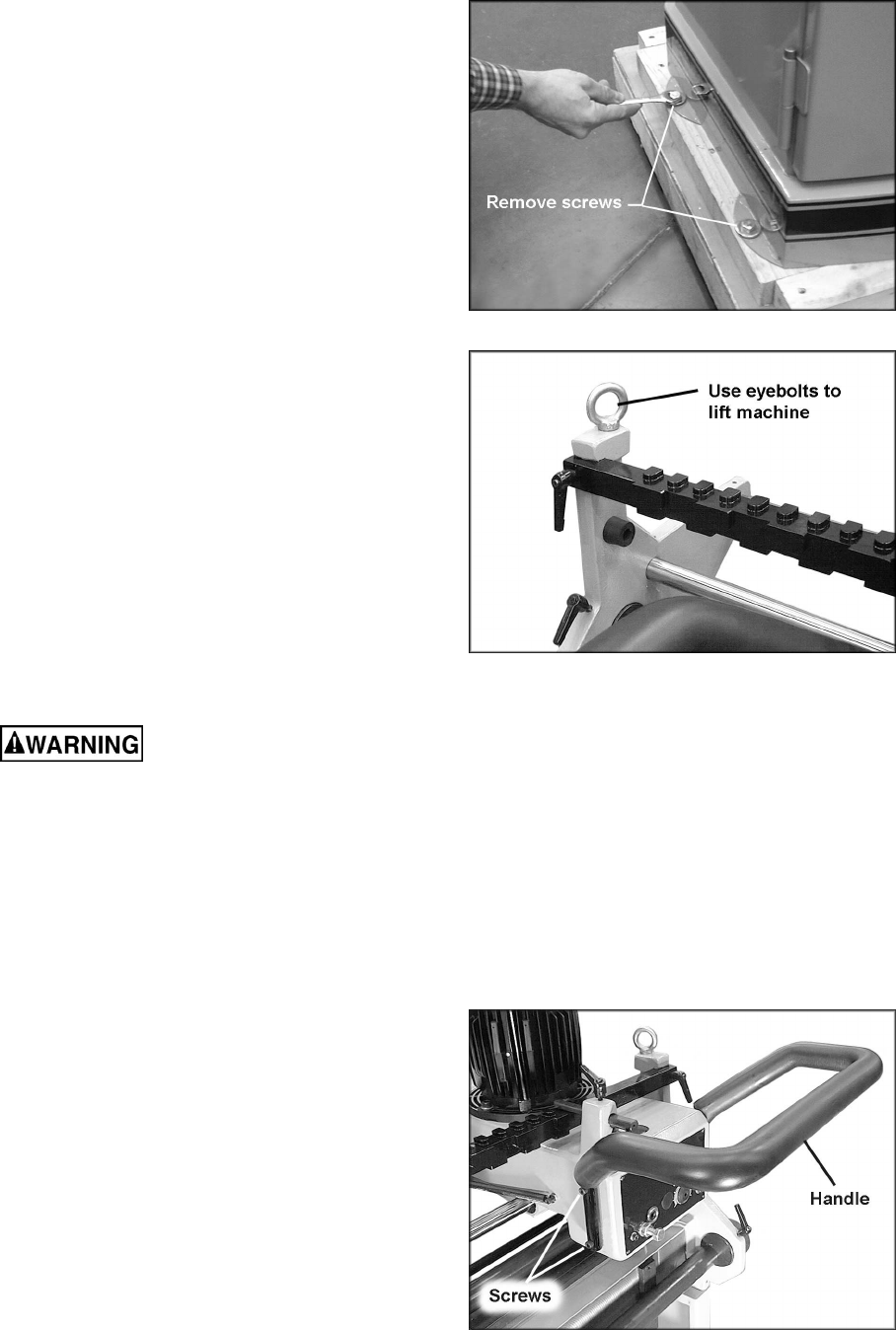

1. Remove the four screws and flat washers

holding the machine to the pallet with an

11mm wrench, as shown in Figure 1.

2. Place lifting straps through the two eyebolts

at the top of the machine (Figure 2). Using

a forklift or hoist, lift the machine off the

pallet and into its desired location. The

Dovetailer should be located in a dry area

with sufficient lighting. Leave plenty of

space around the machine for operations

and routine maintenance work.

3. When the machine is situated, the eyebolts

(Figure 2) can be left on the machine, or

unscrewed and removed, if so desired. Be

sure to retain the eye bolts for future use.

4. If desired, the Dovetailer can be further

stabilized by securing it to the floor, using

lag screws through the four holes at the

bottom of the cabinet.

The dovetailer should be

unplugged from the power source during

assembly procedures.

5. A cord holds the headstock secure to an

eyebolt to prevent the headstock from

moving during shipping. This cord should

now be cut and removed.

6. Exposed metal areas of the dovetailer

(such as the table, template bar, clamp

bars, rods, etc.) have been factory coated

with a protectant. This should be removed

with a soft cloth dampened with kerosene

or mineral spirits. Do not use an abrasive

pad. Do not let solvent contact plastic or

rubber parts as it may damage them.

Installing Handle

The rubber-covered handle (Figure 3) has been

placed backwards for shipping purposes, and

must be reversed before operating the machine.

1. Remove the four socket head cap screws

from the headstock (two of them are holding

the handle), and turn the handle around as

shown in Figure 3.

2. Secure the handle to the headstock with all

four socket head cap screws.

Figure 1

Figure 2

Figure 3