11

Converting from 230 Volt to 460 Volt

Consult the diagrams on pages 54 and 55 for

specific information on the following changes.

1. Disconnect machine from power source.

2. Change the lead connections to the main

motor and to the table hoist motor.

3. Replace the RA-30 (230V) overload relay

with the provided RA-30E (460V) overload

relay.

4. Switch the “R” wire on the transformer from

the 230V to the 460V terminal.

5. If using a plug, install a proper UL/CSA

listed plug suitable for 460V operation.

Test Run

After wiring has been completed, confirm that

the wires have been connected properly:

1. Connect machine to power source and

press the “Main Motor” button for just an

instant, then press the Stop button.

2. The cutterhead should rotate clockwise as

viewed from the handwheel side of the

machine. If cutterhead rotation is incorrect,

disconnect machine from power source

and switch any two of the three wires at

"R,S,T" (see “Electrical Connections”, pages

54 and 55).

3. Re-connect machine to power source.

Controller Set-Up

To program settings in the Controller for table

movement, refer to the section beginnning on

page 20.

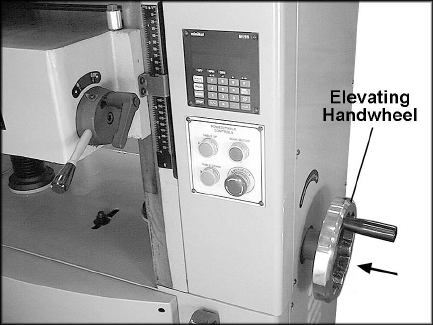

Adjustments

Depth of Cut

Depth of cut is adjusted by raising or lowering

the table using the elevating handwheel or the

push buttons for rough positioning; or the

keypad on the Controller. The Controller is used

for very precise positioning and for remembering

your settings (for more information on the

Controller see the section beginning on page

20).

To move the table with the elevating handwheel

(Figure 3), push the handwheel in to engage the

sprocket on the table elevating mechanism. One

revolution of the handwheel equals 1/32”

change in table height. Use the scale or digital

readout to determine distance from the

cutterhead.

Figure 3