13

2. Remove the top left side panel so that you

can rotate the cutterhead using the belts.

3. To remove a knife insert, unscrew the flat

head screw with a spline screwdriver, or the

air-operated screwdriver using one of the

provided T-20 spline bits. If the screw will

not budge, place the hole of the breaker rod

(A, Figure 7) over a spline bit (B, Figure 7)

and lightly tap the breaker rod

counterclockwise with a hammer to break

loose the screw.

4. Remove the flat head screw, and remove

the knife insert.

5. Carefully wipe clean the insert seat on the

cutterhead and install the new knife insert

(or rotate the present one).

6. The knife insert should be “pre-set” and then

given a final tightening. Install the flat head

screw, and turn the screw until the knife

insert is snug. To pre-set, you may use one

of the spline screwdrivers provided, or use

the air-operated screwdriver set at 45 psi.

7. When finished pre-setting the knife insert,

set the air operated screwdriver to 85 psi,

and fully tighten the screw.

8. Repeat for all knife inserts.

Make sure all knife inserts

are secure in the cutterhead. Failure to

comply may allow knife inserts to loosen and

be flung from the machine during operation.

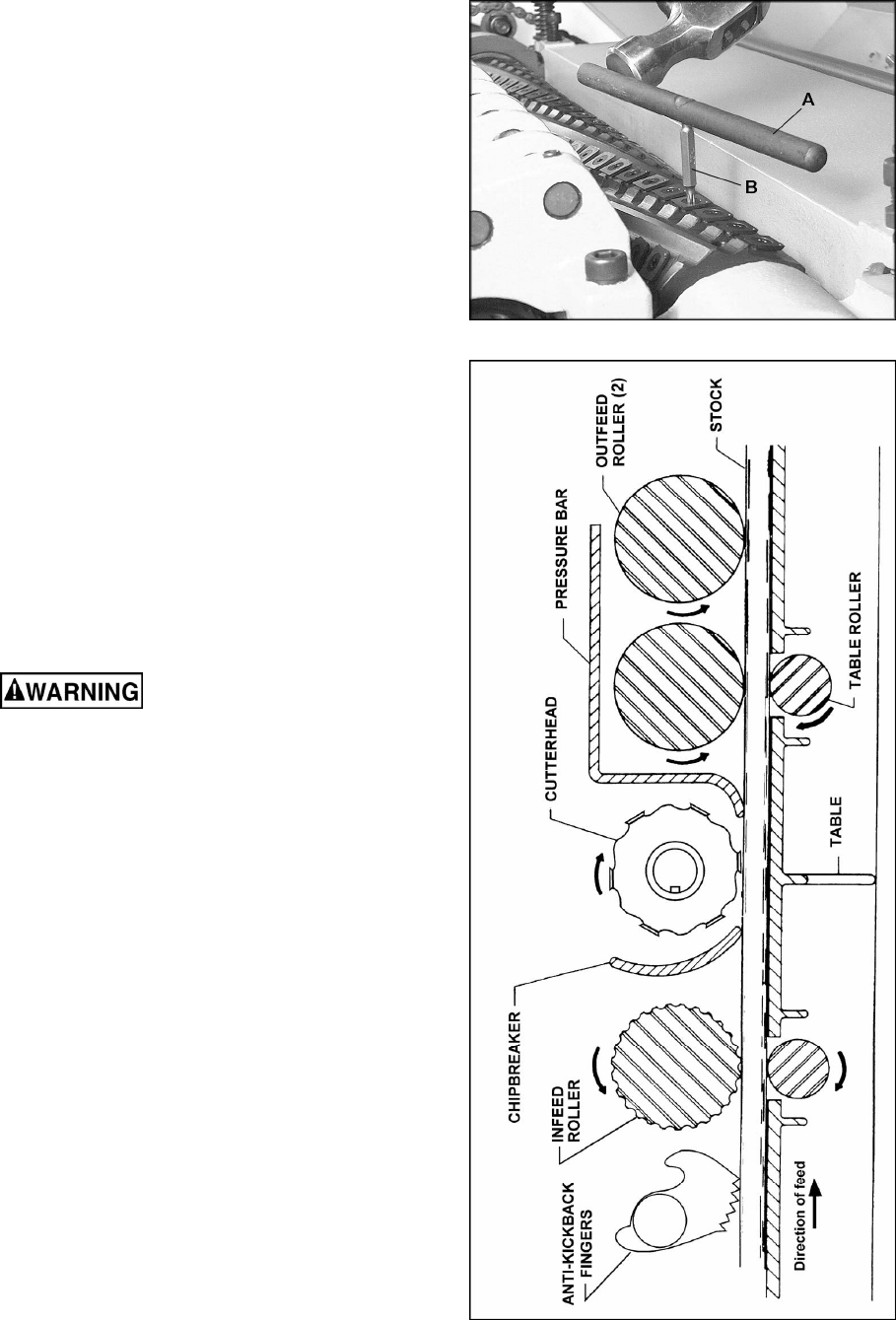

The Planer’s Feed System

(Figure 8)

1. Anti-Kickback Fingers

2. Infeed Roller

3. Chipbreaker

4. Cutterhead

5. Pressure Bar

6. Outfeed Rollers

Anti-Kickback Fingers

Anti-kickback fingers help prevent stock from

being thrown from the machine. These fingers

operate by gravity and should be inspected for

pitch or gum buildup before each day’s use. The

fingers must operate freely and move

independently for correct operation.

Infeed Roller

The function of the infeed roller is to feed the

material into the machine. It is a corrugated,

sectional roller with approximately 1/4”

independent movement of each section to

accomodate multiple board surfacing.

Figure 7

Figure 8