18

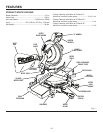

MITER

FENCE

VIEW OF BLADE NOT SQUARE WITH FENCE,

ADJUSTMENTS ARE REQUIRED

FRAMING

SQUARE

MITER

TABLE

BLADE

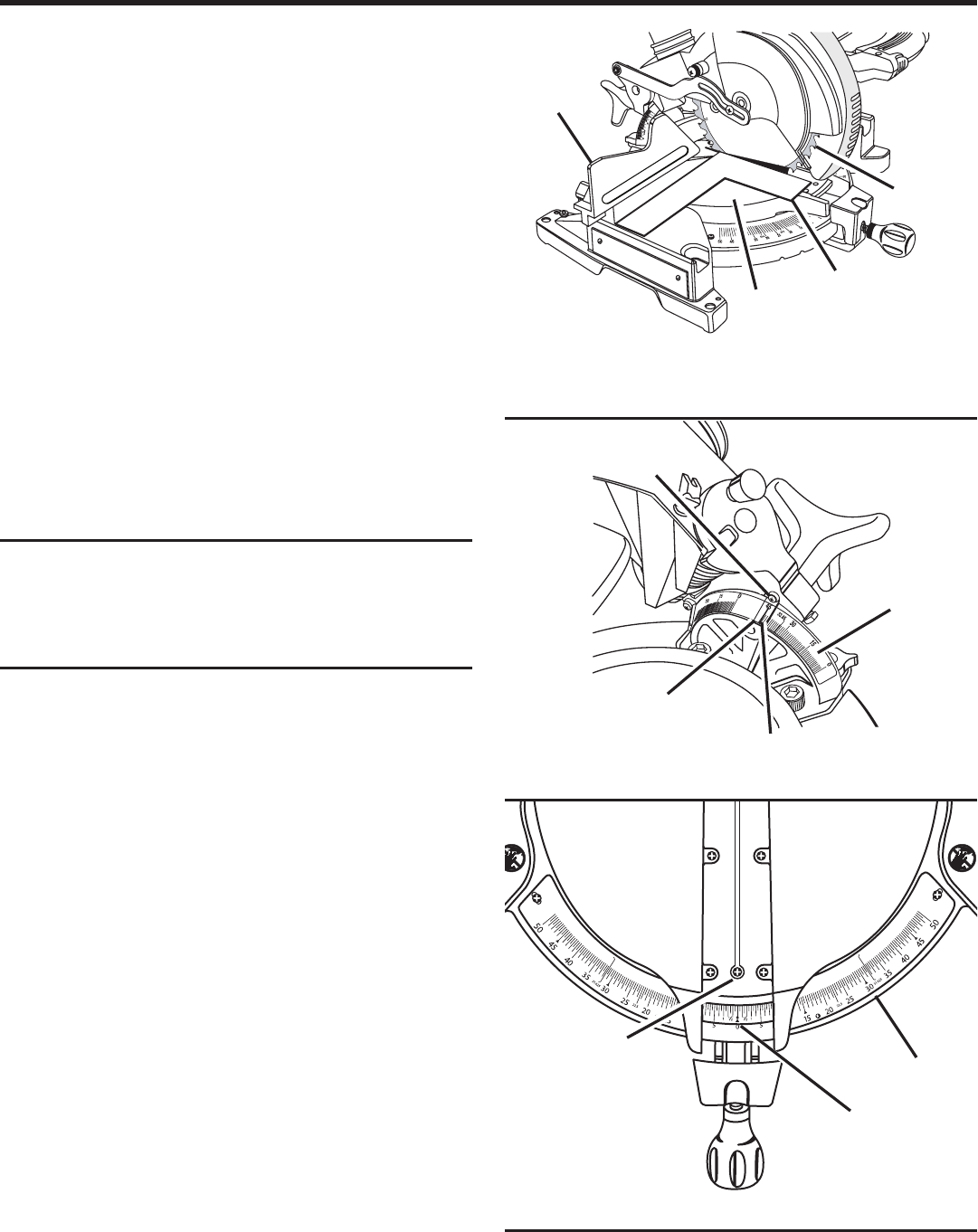

SCALE

INDICATOR

MITER

SCALE

INDICATOR

SCREW

SCALE

INDICATOR

BEVEL

SCALE

INDICATOR

SCREW

INDICATOR

POINT

ASSEMBLY

Fig. 18

Fig. 17

SQUARING THE SAW BLADE TO THE FENCE

See Figures 13 - 18.

Unplug the saw.

Pull the saw arm all the way down and engage the lock

pin to hold the saw arm in transport position.

Loosen the miter lock handle approximately one-half

turn.

Depress the miter lock plate and rotate the miter table

until the pointer on the control arm is positioned at 0

°

.

Release the miter lock plate and securely tighten the miter

lock handle.

Lay a framing square flat on the miter table. Place one

leg of the square against the fence. Slide the other leg

of the square against the flat part of saw blade.

NOTE: Make sure that the square contacts the flat part

of the saw blade, not the blade teeth.

The edge of the square and the saw blade should be

parallel as shown in figure 14.

If the front or back edge of the saw blade angles away

from the square as shown in figures 15 and 16, adjust-

ments are needed.

CAUTION:

To keep from losing control of the unit, steady the

base with one hand while loosening the two bolts

with the other hand.

With the unit securely resting on a large stable surface,

tilt the unit by lifting up on one side of the base.

Using a combination wrench, loosen the two cap head

screws on the underside of the saw table.

Return the saw to its normal resting position. Make sure

the miter lock knob is loose but do not release the miter

lock plate.

Use the miter saw knob to move the table so that the

blade contacts the full length of the framing square. Turn

the miter lock knob clockwise to lock saw square to the

fence.

Tilt the unit by lifting up on one side of the base and

tighten cap head screws.

Recheck blade squareness to fence and readjust if

necessary.

Your saw has several scale indicators. After squaring adjust-

ments have been made, it may be necessary to loosen the

indicators screws and reset them to zero.

See Figure 18.

Fig. 16