26

TROUBLESHOOTING

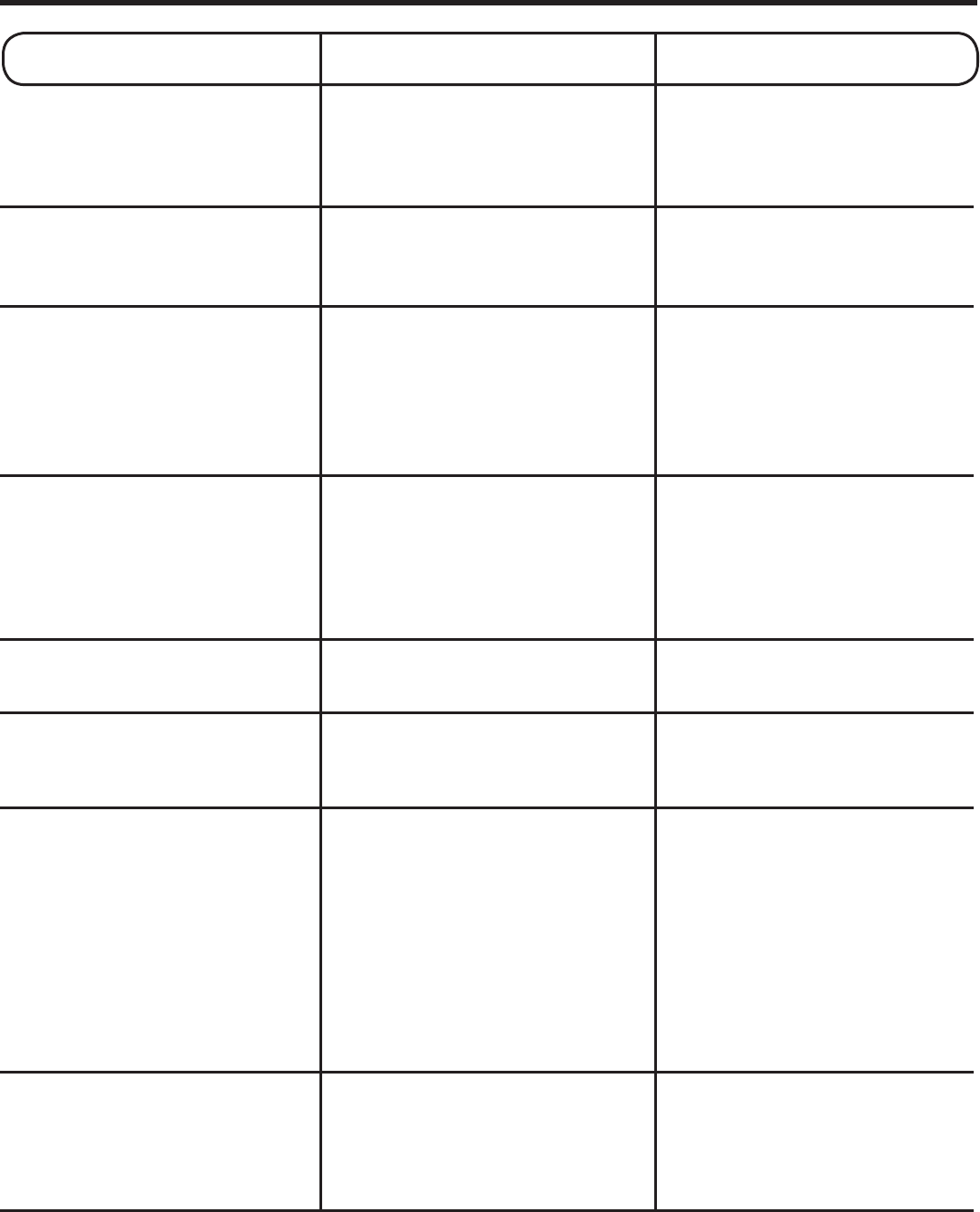

PROBLEM POSSIBLE CAUSE SOLUTION

Snipe (depressions at ends of

workpiece)

Dull cutter blades

Incorrect butted stock

Unit not securely mounted

Replace or turn cutter blades.

Butt pieces end-to-end as they are

fed into planer.

Tighten lag bolts.

Torn grain Too deep a blade setting

Workpiece being fed against grain

Dull cutter blades

Reduce depth of cut.

Feed other end of board first.

Replace or turn cutter blades.

Fuzzy/rough grain High wood moisture content

Dull cutter blades

Too deep a blade setting

Incorrect feeding speed

Dry wood before planing.

Replace or turn cutter blades.

Reduce depth of cut.

Check for adequate power supply.

Check cord and plug for damage.

Check condition of motor brushes.

Uneven depth of cut Cutterhead assembly not level with

planer surface

Unstable roller spring pressure

Feed roller worn unevenly

Adjust elevation nuts.

Have service performed by an

authorized service center.

Have service performed by an

authorized service center.

Board thickness does not match

depth scale indicator

Depth scale incorrectly set

Dirty planing table

Adjust depth scale.

Clean and wax planing table.

Cutterhead height difficult to adjust Dirty spindle

Worn chain

Clean and lubricate spindle.

Have service performed by an

authorized service center.

Will not start Not plugged in

Blown circuit

Motor failure

Loose wire

ON/OFF switch malfunction

Motor is overloaded

Check power source.

Replace fuse, reset breaker, or call

electrician.

Have service performed by an

authorized service center.

Have service performed by an

authorized service center.

Have service performed by an

authorized service center.

Push reset button.

Interrupted operation Unit overloaded

Circuit overloaded

Reduce load.

Operate on circuit separate from

other appliances or motors or con-

nect to circuit with adequate amp

rating.