basic drill press

operation

INSTALLING DRILLS

Insert drill into chuck far enough to obtain maximum

GRIPPING of the CHUCK JAWS ... the jaws are appox. 1

in. long. When using a small drill do not insert it so far that

the jaws touch the flutes (spiral grooves) of the drill.

Make sure that the drill is CENTERED in the chuck before

tightening the chuck with the key.

Tighten the drill sufficiently, so that it does not SLIP while

drilling.

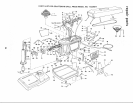

POSITIONING TABLE AND WORKPIECE

Lock the table to the column in a position so that the tip of

the drill is just a little above the top of the workpiece. It is

not necessary to reposition the TABLE SUPPORT

COLLAR each time you reposition the table. Always keep

the collar locked about 34 in. from the floor.

Always place a piece of BACK-UP MATERIAL (wood,

plywood ...) on the table underneath the workpiece. This

will prevent "splintering" or making a heavy burr on the

underside of the workpiece as the drill breaks through.

Position workpiece to butt against the column whenever

possible - if it is too short, clamp solidly to the Table -

this is to prevent the drill bit from grabbing the work from

your hands, which could result in personal injury. A drill

press vise must be fastened to the table.

CAUTION: To prevent the workpiece or the back-up

material from being torn from your hand while drilling,

position them against the left side of the column. Failure to

do this could result in personal injury.

CAUTION: If the workpiece or the back-up material are

not long enough to reach the column, CLAMP them to the

QUILLHANLO _

VCORKPIECE

table. Failure to do this could result in personal injury.

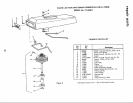

For small pieces that cannot be clamped to the table, use a WORKPIECE

drill press vise (Optional accessory), The vise must be "\

clamped or bolted to the table. \

DRILL PRESS

VISE

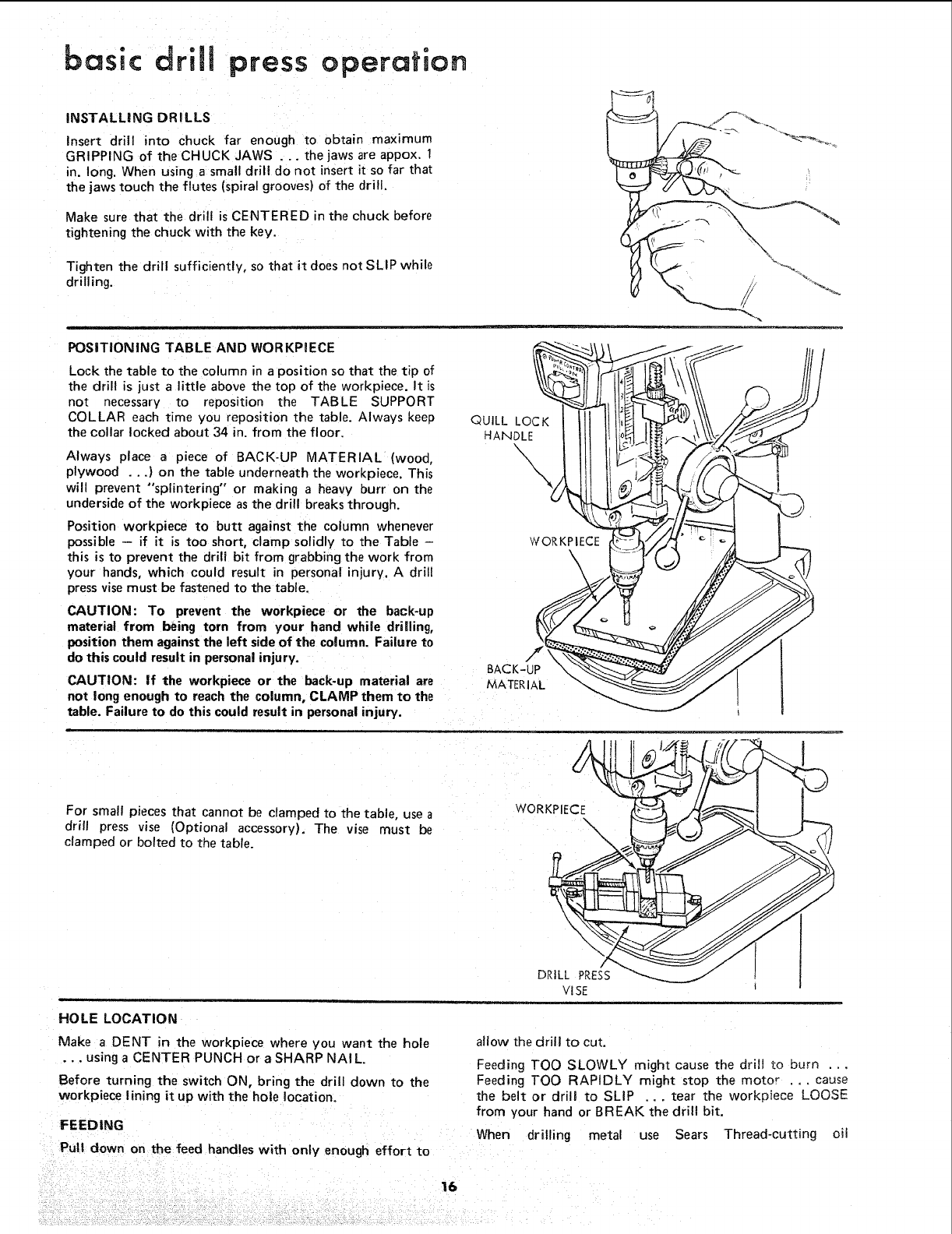

HOLE LOCATION

Make a DENT in the workpiece where you want the hole

... using a CENTER PUNCH or a SHARP NAI L.

Before turning the switch ON, bring the drill down to the

workpiece lining it up with the hole location.

FEEDING

allow the drill to cut.

Feeding TOO SLOWLY might cause the drill to burn ..,

Feeding TOO RAPIDLY might stop the motor .., cause

the belt or drill to SLIP ... tear the workpiece LOOSE

from your hand or BREAK the drill bit.

When drilling metal use Sears Thread-cutting oil

Pull down on the feed handles with only enough effort to

16