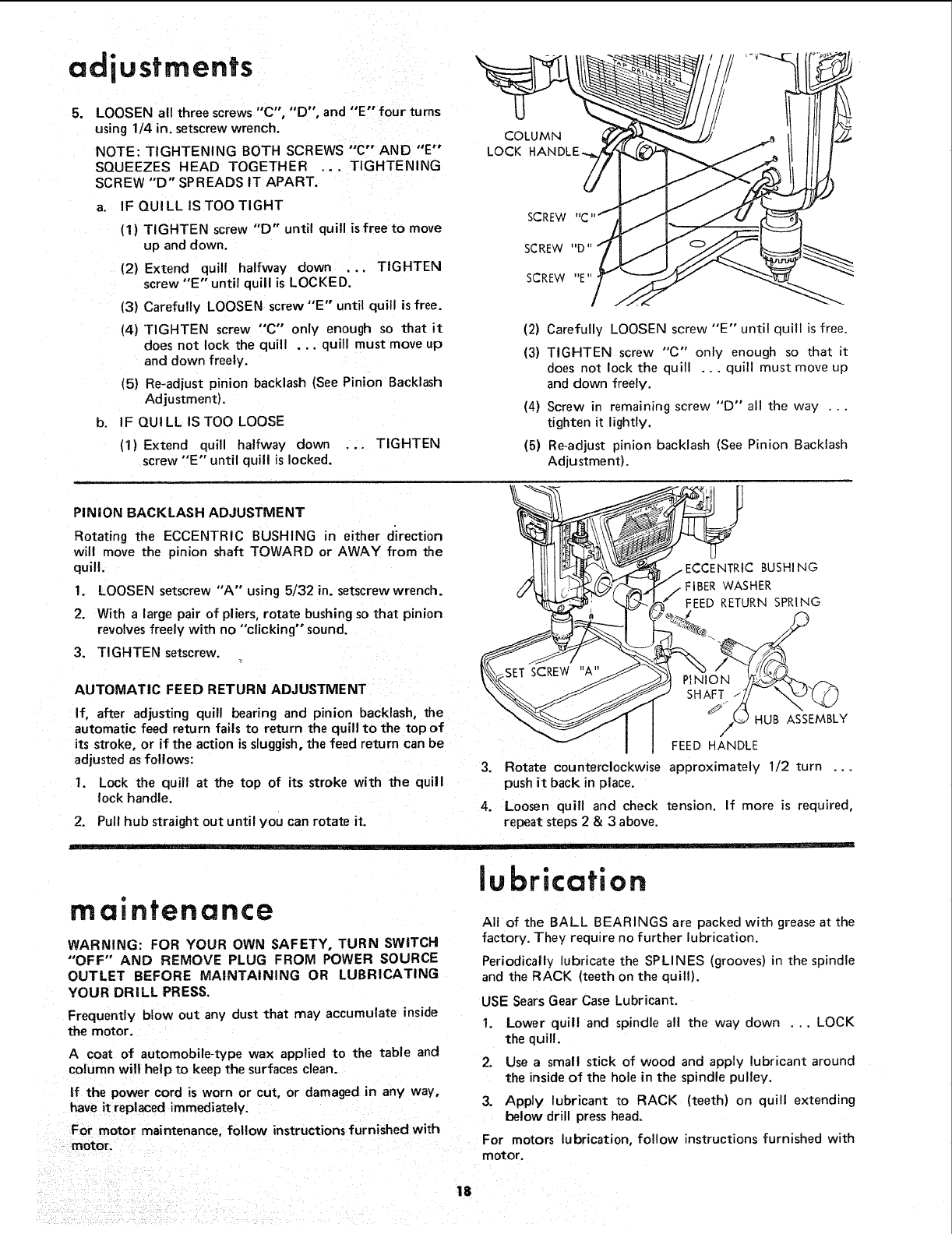

adiustments

5. LOOSEN all three screws "C", "D", and "E'" four turns

using 1/4 in. setscrew wrench.

NOTE: TIGHTENING BOTH SCREWS "C'" AND "E'"

SQUEEZES HEAD TOGETHER ... TIGHTENING

SCREW "'D" SPREADS IT APART.

a. IF QUILL ISTOOTIGHT

(1) TIGHTEN screw "D" until quill is free to move

up and down.

(2) Extend quill halfway down ... TIGHTEN

screw "E" until quill is LOCKED.

(3) Carefully LOOSEN screw "E" until quill is free.

(4) TIGHTEN screw "'C'" only enough so that it

does not lock the quill ... quill must move up

and down freely.

(5) Re-adjust pinion backlash (See Pinion Backlash

Adjustment).

b. IF QUILL ISTOO LOOSE

(1) Extend quill halfway down ... TIGHTEN

screw "'E" until quill is locked.

COLUMN

LOCK

SCREW

SCREW "E"

I

PINION BACKLASH ADJUSTMENT

Rotating the ECCENTRIC BUSHING in either direction

will move the pinion shaft TOWARD or AWAY from the

quill.

1. LOOSEN setscrew "A "°using 5/32 in. setscrew wrench.

2. With a large pair of pliers, rotate bushing so that pinion

revolves freely with no "clicking" sound.

3. TIGHTEN setscrew.

AUTOMATIC FEED RETURN ADJUSTMENT

If, after adjusting quill bearing and pinion backlash, the

automatic feed return fails to return the quill to the top of

its stroke, or if the action issluggish,the feed return can be

adjustedasfollows:

1. Lock the quill at the top of its stroke with the quill

lock handle.

2. Pull hub straight out until you can rotate it.

(2) Carefully LOOSEN screw "E" until quill is free,

(3) TIGHTEN screw "C" only enough so that it

does not lock the quill ... quill must move up

and down freely.

(4) Screw in remaining screw "D" all the way ,..

tighten it lightly.

(5) Re-adjust pinion backlash (See Pinion Backlash

Adjustment).

IC BUSHI NG

3. Rotate counterclockwise approximately 1/2 turn ...

push it back in place.

maintenance

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH

"OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAINTAINING OR LUBRICATING

YOUR DRILL PRESS.

Frequently blow out any dust that may accumulate inside

the motor.

A coat of automobile-type wax applied to the table and

column will help to keep the surfaces clean.

If the power cord is worn or cut, or damaged in any way,

have it replaced immediately.

For motor maintenance, follow instructions furnished with

motor.

4. Loosen quill and check tension. If more is required,

repeat steps 2 & 3 above.

lubrication

All of the BALL BEARINGS are packed with grease at the

factory. They require no further lubrication.

Periodically lubricate the SPLINES (grooves)in the spindle

and the RACK (teeth on the quill).

USE Sears Gear Case Lubricant.

1. Lower quill and spindle all the way down . .. LOCK

the quill.

2. Use a small stick of wood and apply lubricant around

the inside of the hole in the spindle pulley.

3. Apply lubricant to RACK (teeth) on quill extending

below drill press head.

For motors lubrication, follow instructions furnished with

motor.

18