STANDARD SAW OPERATIONS

PRELIMINARY CROSS-CUT AT THE

0 ° POSITION

1. Loosen the carriage lock knob (4, figure 23) and move

the carriage to position the saw just forward of the rip

fence (See figure 22.)

2. Lower the radial arm until the saw blade just clears the

table top.

3. Tighten the carriage lock knob (4, figure 23.)

CAUTION: Before making the cut, make sure

the arm latch handle (8, figure 23) is fully en-

gaged in the detent notch.

4. Plug in the power cord (if not already connected).

5. Insert the safety lock key (figure 24) and pull the switch

lever out to "ON" position.

6. Lower the radial arm, by rotating the elevation crank,

until the saw blade cuts into the table top surface to a

depth of approximately 1/32-inch.

7. Complete the blade clearance groove in the table and

rip fence as follows:

a. Grasp the handle (14, figure 23) with the left hand

and loosen the carriage lock knob (4, figure 23) with

the right hand.

b. Slowly pull the carriage with the right hand out to

the extreme end of its travel.

c. Push the carriage slowly rearward to the extreme

end of the travel. This stroke will cut through the

rip fence.

d. Push the switch to "'OFF" position.

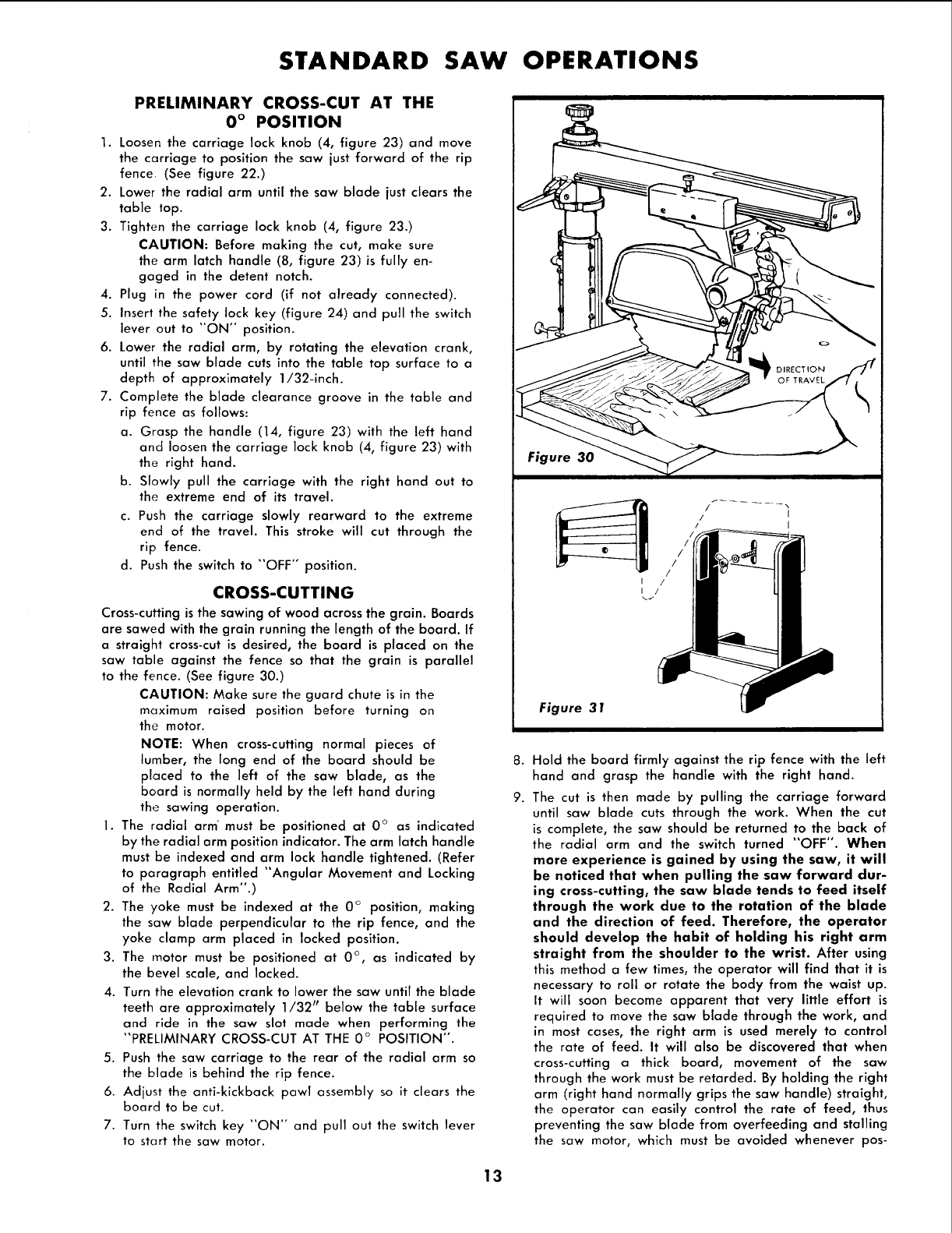

CROSS-CUTTING

Cross-cuttingis the sawing of wood across the grain. Boards

are sawed with the grain running the length of the board. If

a straight cross-cut is desired, the board is placed on the

saw table against the fence so that the grain is parallel

to the fence. (See figure 30.)

CAUTION: Make sure the guard chute is in the

maximum raised position before turning on

the motor.

NOTE: When cross-cutting normal pieces of

lumber, the long end of the board should be

placed to the left of the saw blade, as the

board is normally held by the left hand during

the sawing operation.

1. The radial arm' must be positioned at 0 ° as indicated

by the radial arm position indicator. The arm latch handle

must be indexed and arm lock handle tightened. (Refer

to paragraph entitled "Angular Movement and Locking

of the Radial Arm".)

2. The yoke must be indexed at the 0 ° position, making

the saw blade perpendicular to the rip fence, and the

yoke clamp arm placed in locked position.

3. The motor must be positioned at 0°, as indicated by

the bevel scale, and locked.

4. Turn the elevation crank to lower the saw until the blade

teeth are approximately 1/32 prbelow the table surface

and ride in the saw slot made when performing the

"PRELIMINARY CROSS-CUT AT THE 0 ° POSITION".

5. Push the saw carriage to the rear of the radial arm so

the blade is behind the rip fence.

6. Adjust the anti-kickback pawl assembly so it clears the

board to be cut.

7. Turn the switch key "ON'" and pull out the switch lever

to start the saw motor.

I /

I /

Figure 31

8.

9.

Hold the board firmly against the rip fence with the left

hand and grasp the handle with the right hand.

The cut is then made by pulling the carriage forward

until saw blade cuts through the work. When the cut

is complete, the saw should be returned to the back of

the radial arm and the switch turned "OFF". When

more experience is gained by using the saw, it will

be noticed that when pulling the saw forward dur-

ing cross-cutting, the saw blade tends to feed itself

through the work due to the rotation of the blade

and the direction of feed. Therefore, the operator

should develop the habit of holding his right arm

straight from the shoulder to the wrist. After using

this method a few times, the operator will find that it is

necessary to roll or rotate the body from the waist up.

It will soon become apparent that very little effort is

required to move the saw blade through the work, and

in most cases, the right arm is used merely to control

the rate of feed. It will also be discovered that when

cross-cutting a thick board, movement of the saw

through the work must be retarded. By holding the right

arm /right hand normally grips the saw handle) straight,

the operator can easily control the rate of feed, thus

preventing the saw blade from overfeeding and stalling

the saw motor, which must be avoided whenever pos-

13