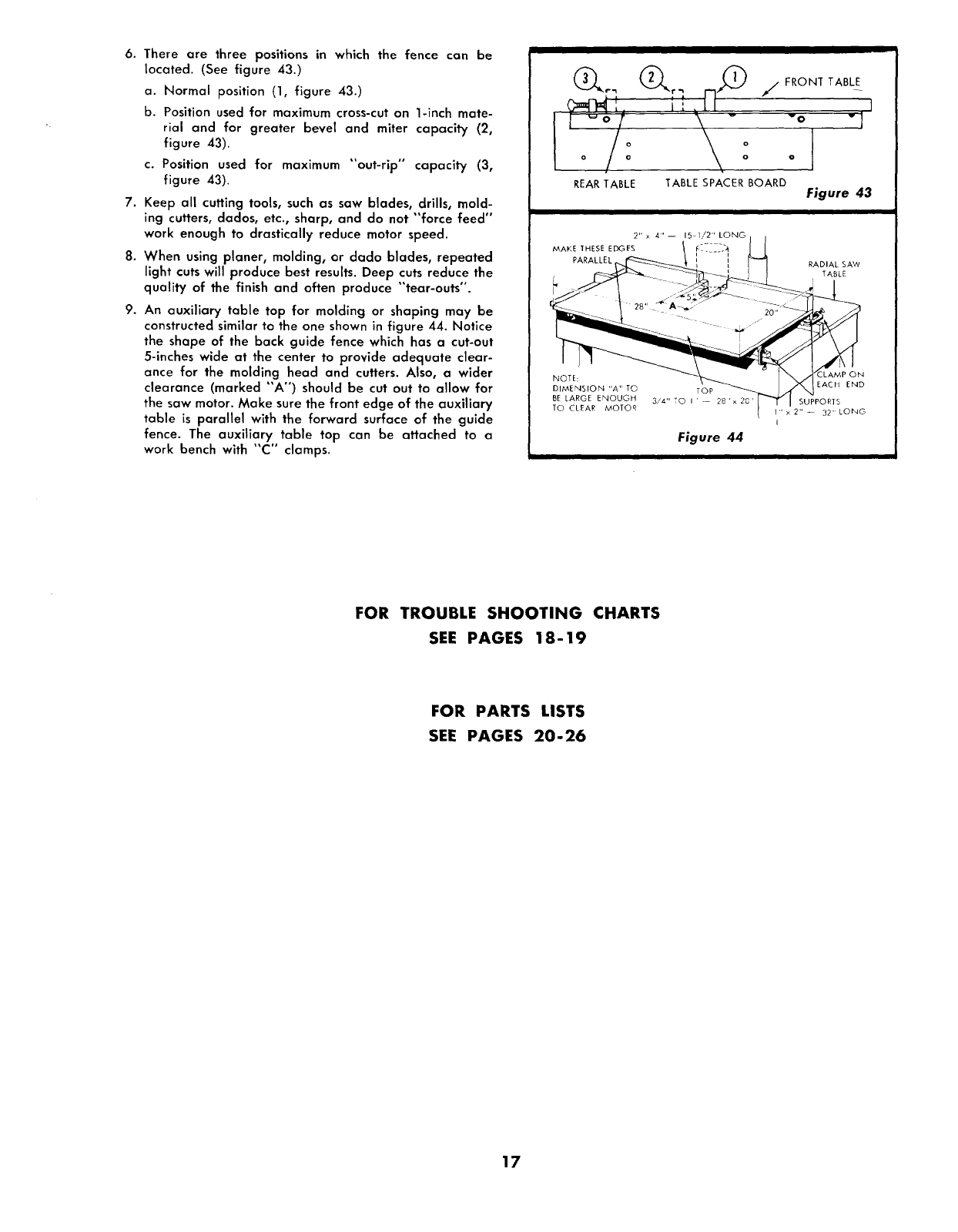

6. There are three positions in which the fence can be

located. (See figure 43.)

a. Normal position (1, figure 43.)

b. Position used for maximum cross-cut on 1-inch mate-

rial and for greater bevel and miter capacity (2,

figure 43).

c. Position used for maximum "out-rip" capacity (3,

figure 43).

7. Keep all cutting tools, such as saw blades, drills, mold-

ing cutters, dados, etc., sharp, and do not "force feed"

work enough to drastically reduce motor speed.

8. When using planer, molding, or dado blades, repeated

light cuts will produce best results. Deep cuts reduce the

quality of the finish and often produce "tear-outs".

9. An auxiliary table top for molding or shaping may be

constructed similar to the one shownin figure 44. Notice

the shape of the back guide fence which has a cut-out

5-inches wide at the center to provide adequate clear-

ance for the molding head and cutters. Also, a wider

clearance (marked "A") should be cut out to allow for

the saw motor. Make sure the front edge of the auxiliary

table is parallel with the forward surface of the guide

fence. The auxiliary table top can be attached to a

work bench with "C '° clamps.

ii

REAR TABLE TABLE SPACER BOARD

f/, FRONT TABLE

I

vO v I

Figure 43

RADIAL SAW

TABLE

Figure 44

I

LAMP ON

EACH END

SUPPORTS

I" x 2" -- 32" LONG

I

FOR TROUBLE SHOOTING CHARTS

SEE PAGES 18-19

FOR PARTS LISTS

SEE PAGES 20°26

17