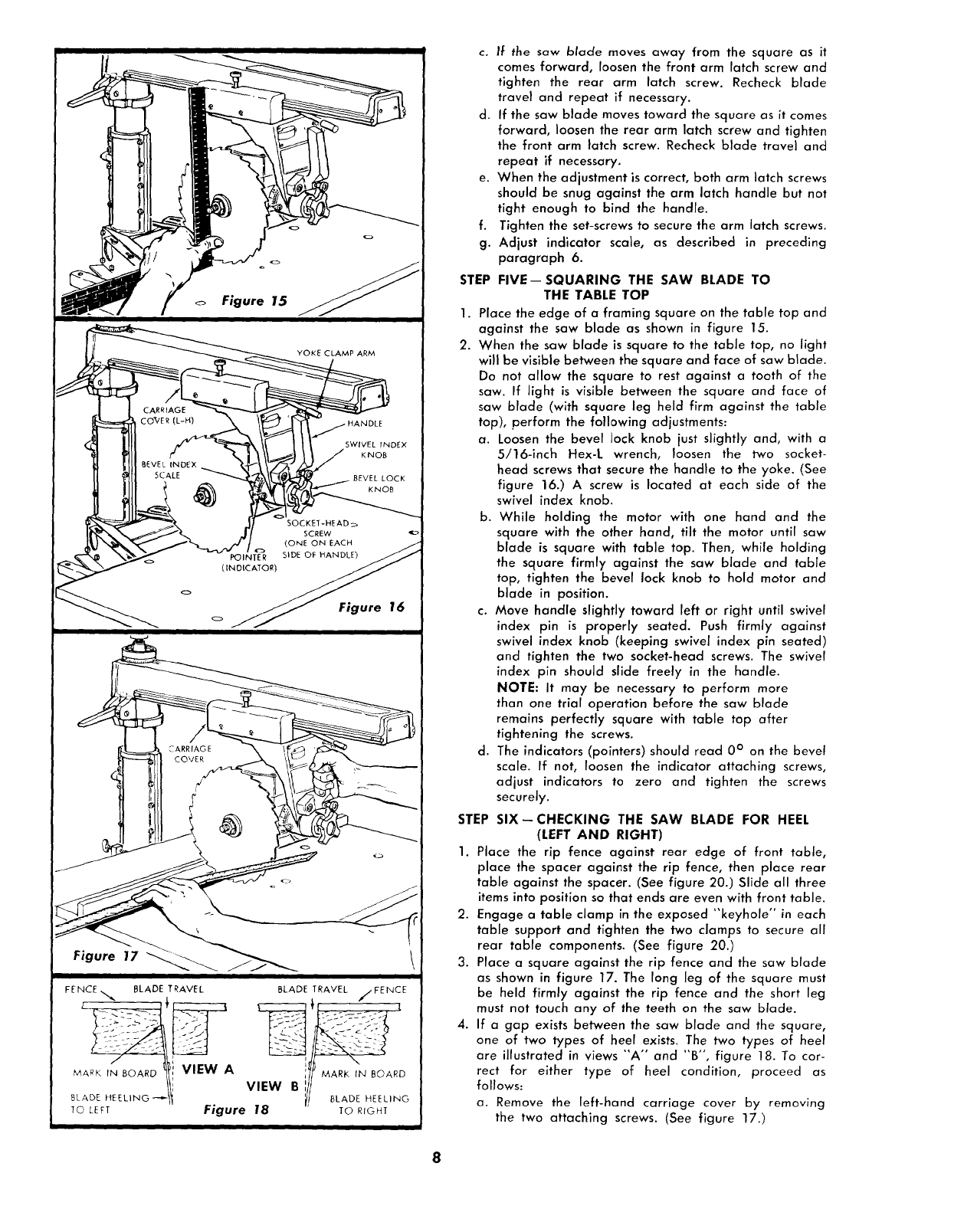

Figure 15

Figure 16

Figure 17

• I

FENCE,,,,,.,, BLADE TRAVEL BLADE TRAVEL //FENCE

BLADE.E EL,.O --ti VIEW Bill MARr._LADE,NHEEL,NGBOARD

To C[FT Figure 18 TO RIOHT

II

f.

g.

STEP

1.

2.

c. If the saw blade moves away from the square as it

comes forward, loosen the front arm latch screw and

tighten the rear arm latch screw. Recheck blade

travel and repeat if necessary.

d. If the saw blade moves toward the square as it comes

forward, loosen the rear arm latch screw and tighten

the front arm latch screw. Recheck blade travel and

repeat if necessary.

e. When the adjustment is correct, both arm latch screws

should be snug against the arm latch handle but not

tight enough to bind the handle.

Tighten the set-screws to secure the arm latch screws.

Adjust indicator scale, as described in preceding

paragraph 6.

FIVE--SQUARING THE SAW BLADE TO

THE TABLE TOP

Place the edge of a framing square on the table top and

against the saw blade as shown in figure 15.

When the saw blade issquare to the table top, no light

will be visible between the square and face of saw blade.

Do not allow the square to rest against a tooth of the

saw. If light is visible between the square and face of

saw blade (with square leg held firm against the table

top), perform the following adjustments:

a. Loosenthe bevel lock knob just slightly and, with a

5/16-inch Hex-L wrench, loosen the two socket-

head screws that secure the handle to the yoke. (See

figure 16.) A screw is located at each side of the

swivel index knob.

b. While holding the motor with one hand and the

square with the other hand, tilt the motor until saw

blade is square with table top. Then, while holding

the square firmly against the saw blade and table

top, tighten the bevel lock knob to hold motor and

blade in position.

c. Move handle slightly toward left or right until swivel

index pin is properly seated. Push firmly against

swivel index knob (keeping swivel index pin seated)

and tighten the two socket-head screws. The swivel

index pin should slide freely in the handle.

NOTE: It may be necessary to perform more

than one trial operation before the saw blade

remains perfectly square with table top after

tightening the screws.

d. The indicators (pointers) should read 0° on the bevel

scale. If not, loosen the indicator attaching screws,

adjust indicators to zero and tighten the screws

securely.

STEP SIX--CHECKING THE SAW BLADE FOR HEEL

(LEFT AND RIGHT)

1. Place the rip fence against rear edge of front table,

place the spacer against the rip fence, then place rear

table against the spacer. (See figure 20.) Slide all three

items into position so that ends are even with front table.

2. Engage a table clamp in the exposed "'keyhole" in each

table support and tighten the two clamps to secure all

rear table components. (See figure 20.)

3. Place a square against the rip fence and the saw blade

as shown in figure 17. The long leg of the square must

be held firmly against the rip fence and the short leg

must not touch any of the teeth on the saw blade.

4. If a gap exists between the saw blade and the square,

one of two types of heel exists. The two types of heel

are illustrated in views "A" and "B", figure 18. To cor-

rect for either type of heel condition, proceed as

follows:

a. Remove the left-hand carriage cover by removing

the two attaching screws. (See figure 17.)

8