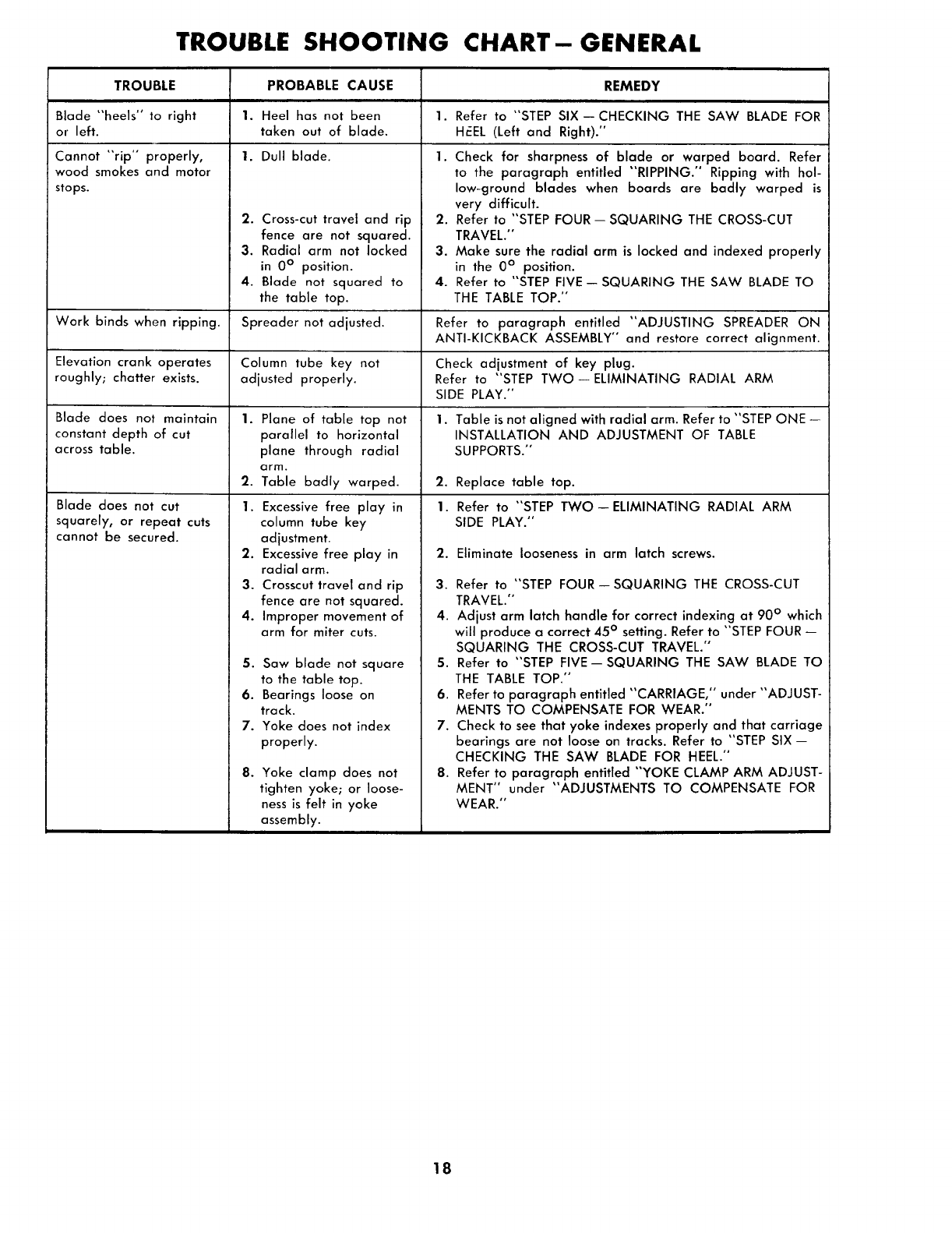

TROUBLE SHOOTING CHART-GENERAL

TROUBLE

Blade "heels" to right

or left.

Cannot "rip" properly,

wood smokes and motor

stops.

Work binds when ripping.

Elevation crank operates

roughly; chatter exists.

Blade does not maintain

constant depth of cut

across table.

Blade does not cut

squarely, or repeat cuts

cannot be secured.

PROBABLE CAUSE REMEDY

1. Heel has not been 1. Refer to "STEP SIX--CHECKING THE SAW BLADE FOR

taken out of blade. Hr_EL(Left and Right)."

1. Dull blade. 1.

2. Cross-cut travel and rip

fence are not squared.

3. Radial arm not locked

in 0° position.

4. Blade not squared to

the table top.

2.

3.

4.

Check for sharpness of blade or warped board. Refer

to the paragraph entitled "RIPPING." Ripping with hol-

low-ground blades when boards are badly warped is

very difficult.

Refer to "STEP FOUR -- SQUARING THE CROSS-CUT

TRAVEL."

Make sure the radial arm is locked and indexed properly

in the 0° position.

Refer to "STEP FIVE -- SQUARING THE SAW BLADE TO

THE TABLE TOP."

Spreader not adjusted. Refer to paragraph entitled "ADJUSTING SPREADER ON

ANTI-KICKBACK ASSEMBLY" and restore correct alignment.

Column tube key not Check adjustment of key plug.

adjusted properly. Refer to "STEP TWO--ELIMINATING RADIAL ARM

SIDE PLAY."

1.

2.

Plane of table top not

parallel to horizontal

plane through radial

arm.

Table badly warped.

1. Excessive free play in

column tube key

adjustment.

2. Excessive free play in

radial arm.

3. Crosscut travel and rip

fence are not squared.

4. Improper movement of

arm for miter cuts.

5. Saw blade not square

to the table top.

6. Bearings loose on

track.

7. Yoke does not index

properly.

B°

Yoke clamp does not

tighten yoke; or loose-

ness is felt in yoke

assembly.

1. Table is not aligned with radial arm. Refer to "STEP ONE --

INSTALLATION AND ADJUSTMENT OF TABLE

SUPPORTS."

2. Replace table top.

1. Refer to "STEP TWO--ELIMINATING RADIAL ARM

SIDE PLAY."

2. Eliminate looseness in arm latch screws.

3. Refer to "STEP FOUR--SQUARING THE CROSS-CUT

TRAVEL."

4. Adjust arm latch handle for correct indexing at 90° which

will produce a correct 45° setting. Refer to "STEP FOUR --

SQUARING THE CROSS-CUT TRAVEL."

5. Refer to "STEP FIVE--SQUARING THE SAW BLADE TO

THE TABLE TOP."

6. Refer to paragraph entitled "CARRIAGE," under "ADJUST-

MENTS TO COMPENSATE FOR WEAR."

7. Check to see that yoke indexes properly and that carriage

bearings are not loose on tracks. Refer to "STEP SIX-

CHECKING THE SAW BLADE FOR HEEL."

8. Refer to paragraph entitled "YOKE CLAMP ARM ADJUST-

MENT" under "ADJUSTMENTS TO COMPENSATE FOR

WEAR."

18