7. Start the leveling screw into the T-nut on front table, but

do not allow the tip of the screw to protrude beyond the

bottom surface of front table.

8. Install Iockwashers and nuts on the six screws in the

table supports and tighten them finger tight. Start the

pan-head screw in the counterbored hole near the

center of front board into the U-nut on saw base, but

leave it approximately two turns loose.

9. At this time the front table should be checked and ad-

justed at the center position as follows:

a. Move carriage to maximum rear position.

b. Using one edge of the rear table board as a straight-

edge, lay the board on the front table as shown

in figure 10.

c. Sight between edge of rear table and surface of front

table, to determine if the front table is low or high

at the center position. If front table is high, tighten

the center hold-down screw until it is level, then rotate

the leveling screw clockwise until it is "snug" against

the base front member. If the table is low at the

center, loosen the hold-down screw and rotate the

leveling screw clockwise until the front table is level,

then tighten the hold-down screw.

NOTE: After tightening screws, as described

above, always recheck to make sure that the

front table remains level. In some cases, a final

"touch-up" adjustment may be required.

STEP FOUR--SQUARING THE CROSS-CUT TRAVEL

1. Loosen the bevel lock knob, pull out on swivel index

knob and swivel the motor until the swivel index knob

indexes the motor with the shaft in a horizontal (zero)

position. Tighten the bevel lock knob.

2. Check to make sure the arm latch handle is securely

latched in the detent an_l the arm lock handle is still tight.

3. Install the saw blade as follows:

a. Place the inner collar on motor shaft. (See figure 4.)

b. Slide saw blade on motor shaft. Make sure teeth are

pointed in direction of saw rotation. (See figure 42

c. Install outer collar and arbor nut.

NOTE: The arbor shaft has left-hand threads.

d. Usethe shaft wrench on motor shaft and arbor wrench

on arbor nut to tighten the nut, as shown in figure 11.

e. Lower the saw blade (with elevation crank) until the

blade isapproximately 1/32 inch above table surface.

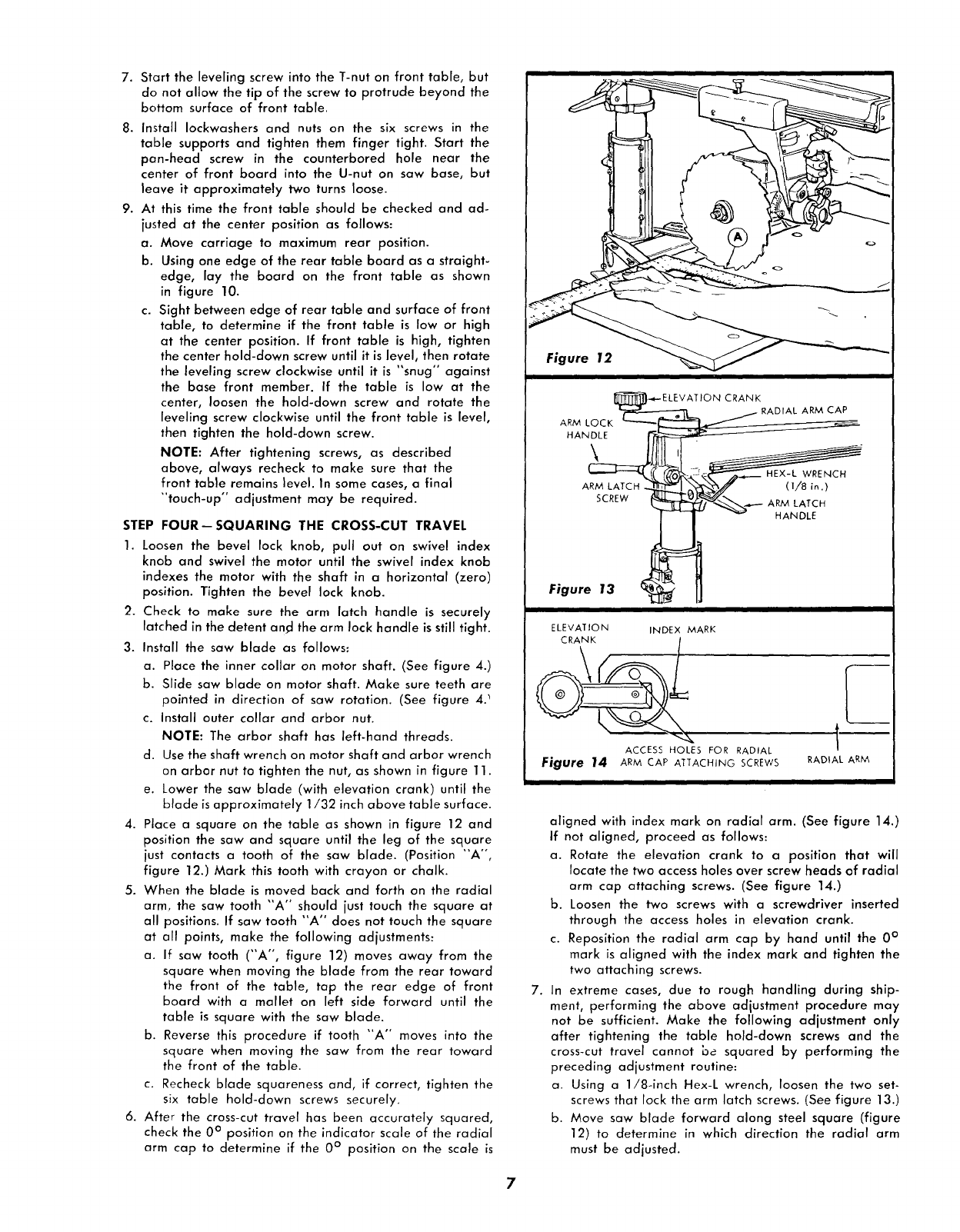

4. Place a square on the table as shown in figure 12 and

position the saw and square until the leg of the square

just contacts a tooth of the saw blade. (Position "A °',

figure 12.) Mark this tooth with crayon or chalk.

5. When the blade is moved back and forth on the radial

arm, the saw tooth "A '° should just touch the square at

all positions. If saw tooth "A" does not touch the square

at oil points, make the following adjustments:

a. If saw tooth ("A", figure 12) moves away from the

square when moving the blade from the rear toward

the front of the table, tap the rear edge of front

board with a mallet on left side forward until the

table is square with the saw blade.

b. Reverse this procedure if tooth "A" moves into the

square when moving the saw from the rear toward

the front of the table.

c. Recheck blade squareness and, if correct, tighten the

six table hold-dawn screws securely.

6. After the crass-cut travel has been accurately squared,

check the 0° position on the indicator scale of the radial

arm cap to determine if the 0° position on the scale is

Figure 12 _ _ -

i

J_]_.-,,_- ELEV AT IO N CRANK

ARM LO _ -- _ j RADIAL ARM CAP

CK i "_

HANDLE _ _

l _ HANDLE

Figure 13 _ ! _

ELEVATION INDEX MARK

ACCESS HOLES FOR RADIAL

Fjgure 14 ARM CAP AIi"ACHING SCREWS

,L

RADIAL ARM

aligned with index mark on radial arm. (See figure 14.)

If not aligned, proceed as follows:

a. Rotate the elevation crank to a position that will

locate the two access holes over screw heads of radial

arm cap attaching screws. (See figure 14.)

b. Loosen the two screws with a screwdriver inserted

through the access holes in elevation crank.

c. Reposition the radial arm cap by hand until the 0 °

mark is aligned with the index mark and tighten the

two attaching screws.

7. In extreme cases, due to rough handling during ship-

ment, performing the above adjustment procedure may

not be sufficient. Make the following adjustment only

after tightening the table hold-down screws and the

cross-cut travel cannot be squared by performing the

preceding adjustment routine:

a. Using a 1/8-inch Hex-L wrench, loosen the two set-

screws that lock the arm latch screws. (See figure 13.)

b. Move saw blade forward along steel square (figure

12) to determine in which direction the radial arm

must be adjusted.

7