-8-

Mfg. Since 10/09

SB1363-64/SB1367-68

PREPARATION

Vertical Installation

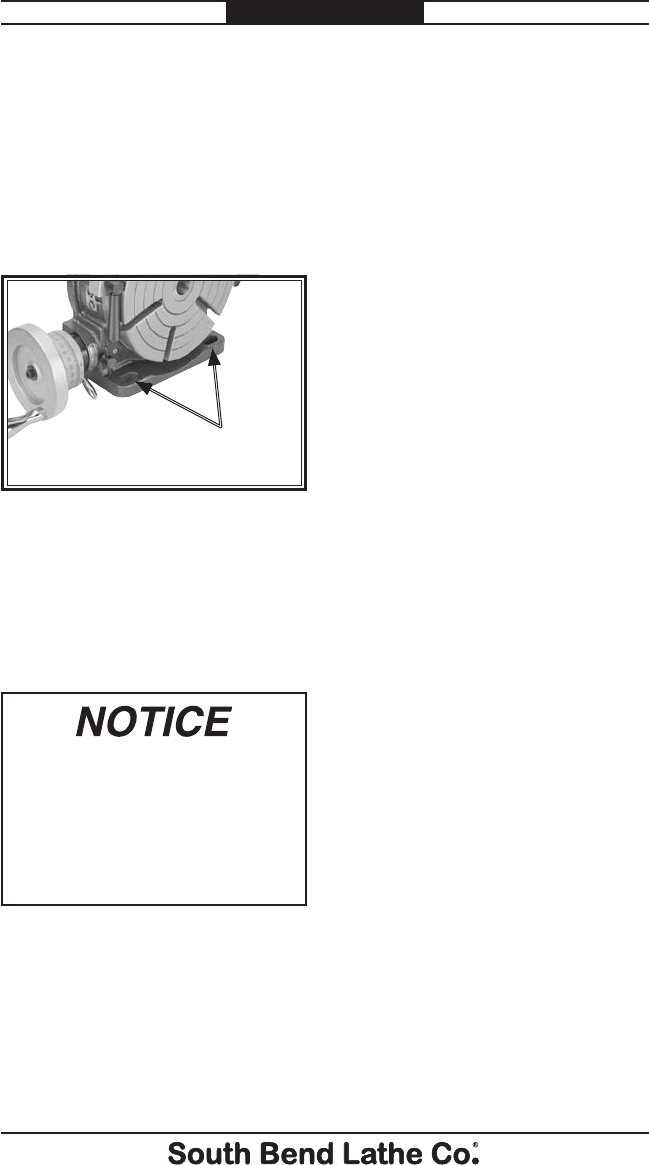

Compare the center to center

distance between the mill table

T-slots to the vertical mounting

holes on the rotary table foot (see

Figure 4). If the mounting holes do

not intersect the mill table T-slots

with sufficient space for T-bolts, use

step blocks and clamps in place of

one of the T-bolts.

Figure 4. Locations of the vertical

mounting holes.

Vertical

Mounting Holes

To mount the rotary table vertically:

1. DISCONNECT MILL FROM

POWER!

2. Insert the clamping hardware

into the outer mill table T-slots.

Make sure the rotary

table handwheel is free of

obstructions. Depending on your

setup, the rotary table may need

to be blocked up or mounted so

the handle is hanging over the

edge of the mill table.

3. Place the rotary table on the

mill table so that you can use

the clamping hardware to secure

it in the next step.

4. Placethemachinist'ssquare

along the front of the mill table

and the machined side of the

rotary table foot, square the

rotary table to the mill table,

then fully tighten the clamping

hardware.

5. Perform the Vertical

Installation Alignment

procedure as instructed on

Page 10.

Aligning to Spindle

Centerline

Whether the rotary table is mounted

horizontally or vertically, you must

align the rotary table centerline

to the mill spindle centerline to

achieve quality results. Also, the

spindle centerline must first be

properly aligned to mill table in both

the X- and Y- axis (this procedure

is generally called "tramming the

spindle").

There are many methods for

aligning the centerlines, and it

is up to the machinist and their

capabilities to decide which

approach is best.