-17-

SB1363-64/SB1367-68Mfg. Since 10/09

MAINTENANCE

Lubrication

The recommended schedule

on the previous page for the

lubrication tasks is based on

light-to-medium usage. Keeping

in mind that lubrication helps to

protect the value and operation

of the rotary table, these

lubrication tasks may need to be

performed more frequently than

recommended, depending on

usage.

Failure to follow reasonable

lubrication practices as

instructed in this manual could

lead to premature failure of the

rotary table components and will

void the warranty.

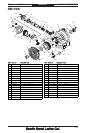

Ball Oilers

There are two ball oilers (see

Figure 14) that must be lubricated

before daily use, or more often with

heavy use.

Figure 14. Locations of the two ball

oilers.

Ball Oilers

Important: Use an oil can or gun

that has a plastic or rubber tip.

Metal tips can damage the ball and

spring inside the oilers.

Clean away debris and grime from

around the ball oilers, then depress

the ball with the oil can tip to add

oil until it is seen exiting between

the parts. Clean away any excess

lubricant, then rotate the table at

least one full revolution to evenly

disperse the lubricant.

Worm Gear & Shaft

To gain access to the worm gear and

shaft for cleaning and lubrication,

you need to remove the table from

the cast iron housing.

Items Needed Qty

Hex Wrench 3mm. . . . . . . . . . . . . . 1

Dead Blow Hammer ............1

Stiff-Bristled Brush . . . . . . . . . . . . 1

Shop Rags ............ As Needed

Mineral Spirits ........ As Needed

MP Gear Grease ....... As Needed

To remove the table and clean/

lubricate the worm gear and shaft:

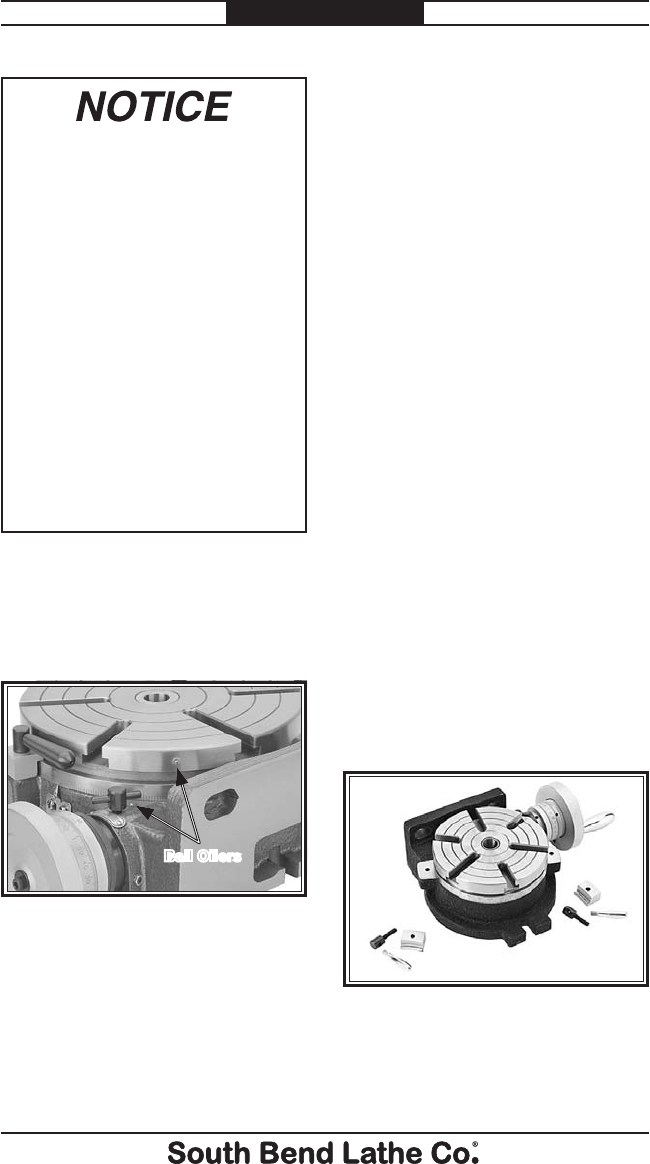

1. Remove the table lock

assemblies, as shown in

Figure 15.

Figure 15. Table lock assemblies

removed (Model SB1364 shown).