-13-

SB1363-64/SB1367-68Mfg. Since 10/09

OPERATION

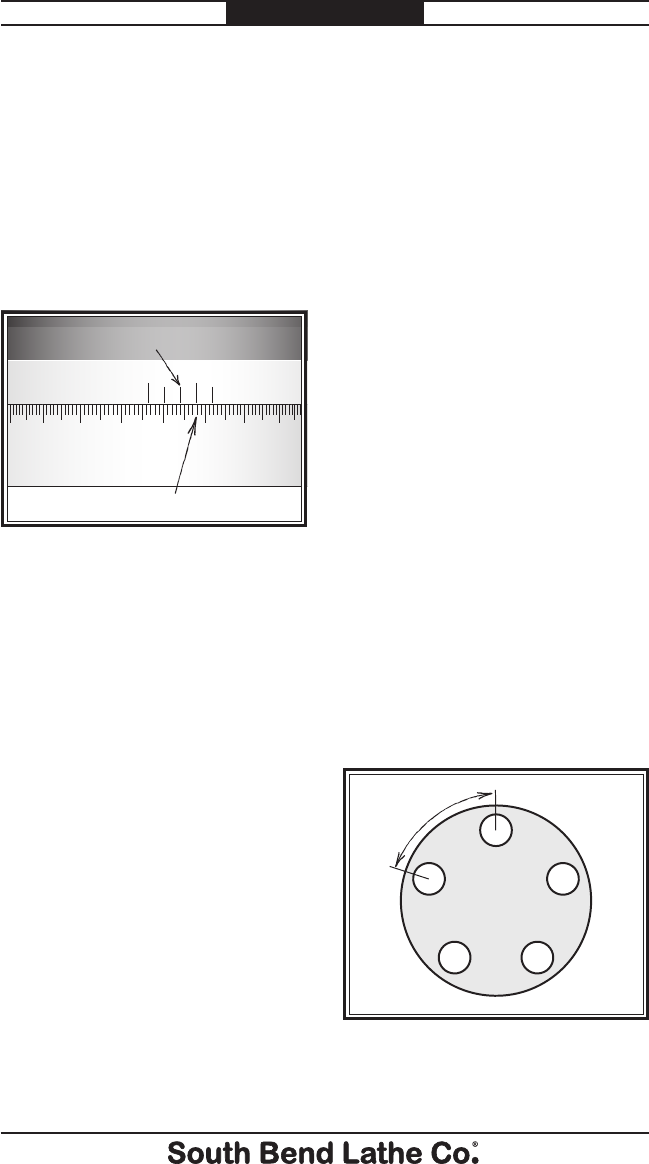

2. Slowly continue to turn the

handwheeluntilthe32'markon

the handwheel scale aligns with

the 0° mark on the vernier scale

(see the illustrated example in

Figure 11).

Note: Figure 11 may not agree

with the layout of the scales on

your model. However, the use of

these scales as instructed here

is the same.

Figure 11. Handwheel and vernier

scales aligned so that the table is at

16° 32' 20".

0

60

40

30

20

10

0

50

10

20

30

40

5

0

1

32 Arc Minutes

20 Arc Seconds

Vernier Scale

Handwheel Scale

3. Identify the mark on the vernier

scale that is two marks (20") to

the left of the vernier scale 0°

mark.

Important: When the handwheel

is turned clockwise, the marks

to the left of the vernier scale

0° mark are used, and when

the handwheel is turned

counterclockwise, the marks on

the right are used.

4. Identify the mark on the

handwheel scale that is

immediately to the left of the

vernier scale 20" mark, then

slowly rotate the handwheel

clockwise until the this mark

and the vernier scale 20" mark

are aligned. The table is now set

at16°32'20".

Operational Examples

Use your rotary table and mill to

follow along with the operational

examples below to better

understand how to use the rotary

table.

Note: For both examples, the

following statements are assumed to

be true:

• Therotarytableisproperly

secured to the mill in the

horizontal position.

• Therotarytableisproperly

centered with the mill spindle

centerline.

• Theworkpieceiscenteredand

properly clamped on the rotary

table, and elevated for proper

machining clearances.

• The0°marksofthehandwheel

and vernier scales are aligned.

Five Evenly Space Holes

In this example, you will make

five holes spaced 72° apart in a

circular workpiece, as illustrated in

Figure 12.

Figure 12. Five hole layout spaced 72°

apart.

72º