-10-

Mfg. Since 10/09

SB1363-64/SB1367-68

PREPARATION

7. Repeat the above steps for the

mill table Y-axis.

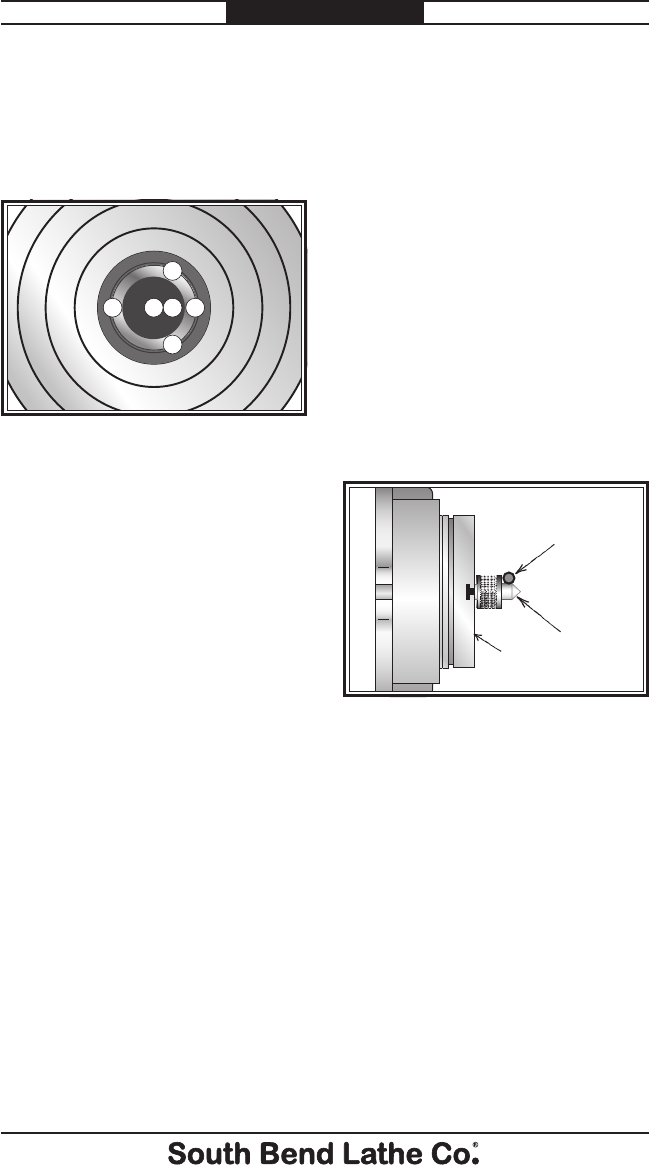

Note: Use the pattern illustrated in

Figure 6 to aid in positioning

the edge finder for the above

procedure.

Figure 6. Pattern of positioning the edge

finder to the rotary table spindle bore.

1

2

3

4

5

6

Vertical Installation

Alignment

In these procedures, you will verify

the rotary table alignment with the

mill spindle from front to back and

to its centerline.

To verify the front-to-back alignment

of the rotary table to the mill

spindle:

1. DISCONNECT MILL FROM

POWER!

2. Mount a test indicator to the

mill spindle and position the

indicator tip on one end of the

rotary table face.

3. Move the mill table along the

Y-axis and note any deviations

in the test indicator.

— If a deviation is found, loosen

the rotary table mounting

fasteners, tap the rotary

table into the proper position,

then re-tighten the mounting

fasteners.

4. Repeat Step 3 until the entire

rotary table surface is correctly

aligned with the mill spindle.

To center the rotary table with the

mill spindle centerline:

1. DISCONNECT MILL FROM

POWER!

2. Fully seat a lathe center into the

rotary table spindle.

Note: Any center runout will have to

be determined and accounted for

in the following steps.

3. Use an edge finder mounted in

the mill spindle to find the edge

of the center, as illustrated in

Figure 7.

Figure 7. Using an edge finder and center

to align the rotary table (top view).

Edge

Finder

Lathe

Center

Rotary

Table

Top View

4. Measure the diameter of the

center where the edge finder

makes contact, divide this

number in half, then add half of

the edge finder diameter. The

result is the amount you need

to move the mill table along the

Y-axis to center the rotary table

with the mill spindle centerline.

Note: Be sure to take into account

any backlash and any rounout

of the center when moving the

table.