-18-

Mfg. Since 10/09

SB1363-64/SB1367-68

MAINTENANCE

2. Use the backlash adjustment

ring to disengage the gears from

the handwheel so that the table

rotates freely by hand.

3. Turn the rotary table upside

down on a protective surface.

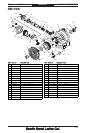

4. Loosen the cap screw that

secures the spindle lock collar,

then unthread and remove the

collar (see Figure 16).

Figure 16. Loosening the spindle lock

collar cap screw.

Lock

Collar

5. Lift the edge of the cast iron

housing with one hand, and tap

the back end of the spindle with

the dead blow hammer until the

table assembly breaks free from

the housing.

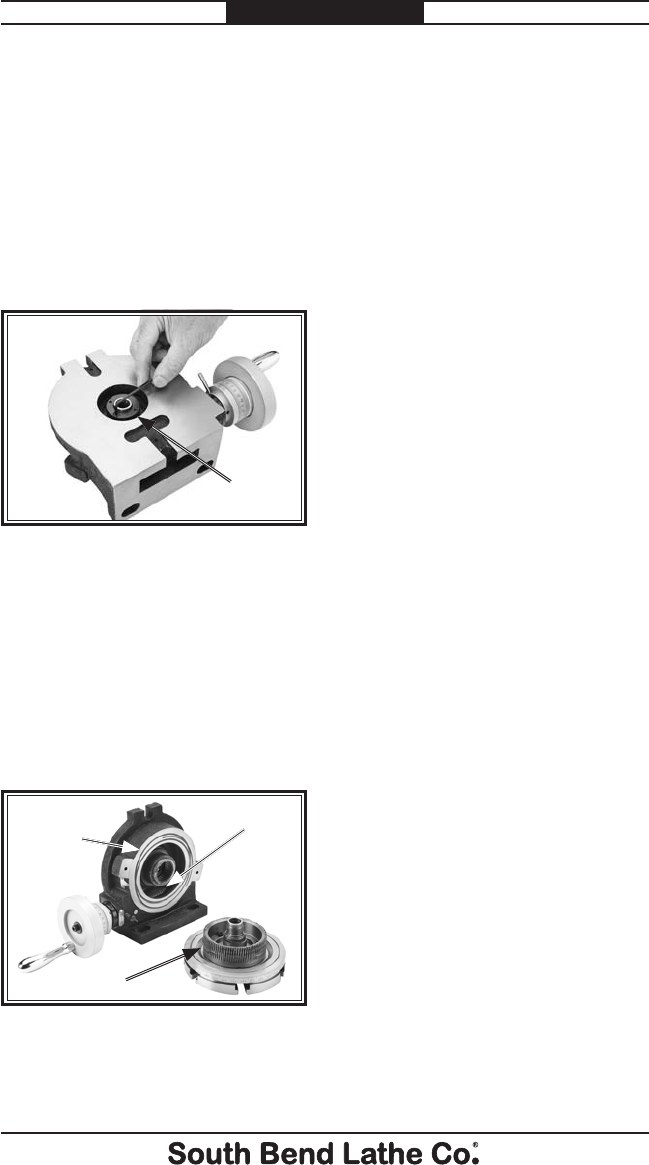

6. Remove the table from the

housing, as shown in Figure 17.

7. Use the stiff-bristled brush,

shop rags, and mineral spirits

to clean grime and debris from

inside the housing cavity, the

worm shaft, and the worm gear.

8. When these parts are dry, apply

a medium coat of multi-purpose

gear grease to the teeth of the

worm shaft and gear.

9. Use a clean shop rag and

mineral spirits to wipe clean

the mating surfaces of the

housing and table, then apply

a thin coat of light machine

oil to the housing oil grooves

and surrounding surface (see

Figure 17).

10. Re-install the table, the spindle

lock collar, and the table lock

assemblies, then perform the

Spindle Preload procedure as

instructed on the next page.

Figure 17. Locations of worm gear and

shaft with the table removed.

Worm Shaft

Worm Gear

Oil

Grooves