-70-

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

MAINTENANCE

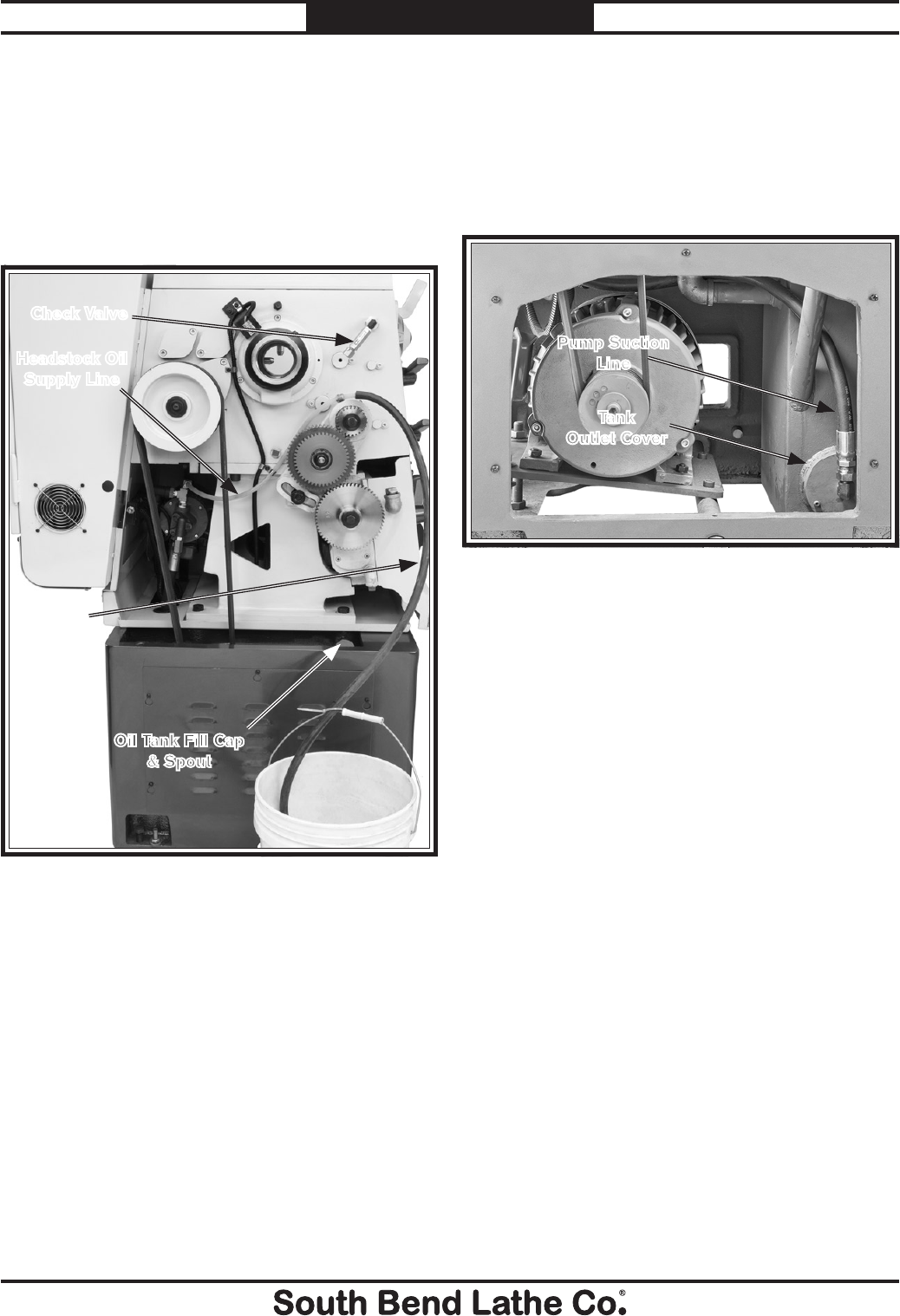

To to change the headstock oil:

1. DISCONNECT LATHE FROM POWER!

2. Remove the end gear cover, the tank access

cover, and the oil tank fill cap.

3. Remove the headstock oil supply line from

the check valve (see Figure 101).

4. Push the drain hose onto the headstock oil

supply line. If necessary, use a hose clamp to

ensure a tight connection.

5. Hold the other end of the drain tube in the

bucket, then turn the master power switch

ON and reset the STOP button. The oil

pump will start pumping oil from the tank

and into the bucket.

6. As soon as you hear a sucking sound from

the tank or when the oil slows or stops

flowing out, turn the master power switch

OFF to stop the pump.

7. Remove the drain hose and re-connect the

headstock oil supply line to the check valve.

8. Place rags under the tank outlet cover to

catch the residual oil in the tank when

the cover is removed in the next step (see

Figure 102).

9. Remove the pump suction line from the tank

outlet cover, remove the three cap screws

that secure the cover, then carefully remove

the cover.

10. Use mineral spirits and rags to clean the

inside of the tank. Make sure to soak up any

excess mineral spirits with dry rags so that

it does not stay in the tank and contaminate

the oil.

Tip: Consider placing one or two magnets at the

bottom of the tank to collect any fine metal

particles. This will make cleaning easier the

next time around and reduce the amount of

metal particles that may end up in the oil.

11. Re-install the tank outlet cover with a new

gasket or silicone sealant.

12. Place the funnel in the fill spout and add the

new oil.

13. Re-install the tank fill cap and end gear and

tank access covers, then test the oil pump

operation.

Figure 102. Location of tank outlet cover.

Tank

Outlet Cover

Pump Suction

Line

Figure 101. Draining headstock oil.

Headstock Oil

Supply Line

Check Valve

Rubber

Drain

Hose

Oil Tank Fill Cap

& Spout