-80-

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

SERVICE

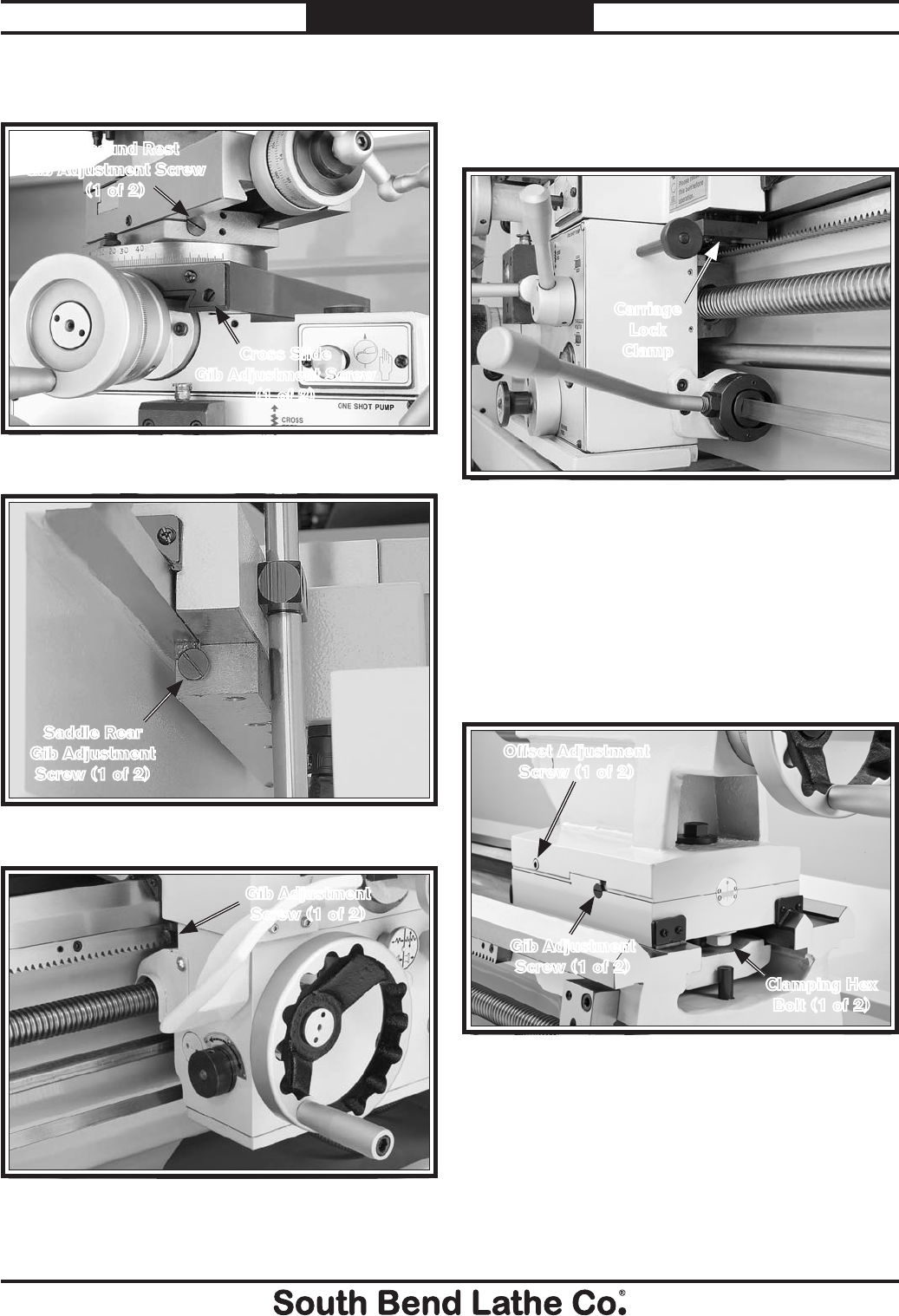

Figure 118. Compound and cross slide gib adjustment

screws.

Compound Rest

Gib Adjustment Screw

(1 of 2)

Cross Slide

Gib Adjustment Screw

(1 of 2)

Note: Remove the thread dial body and the

carriage lock clamp to access the saddle gib

adjustment screw on the tailstock side (see

Figure 121).

Note: Before adjusting the tailstock gib, loosen

the clamping hex bolts underneath both ends

of the tailstock (see Figure 122) to release the

clamping pressure between the upper and lower

castings. Test the gib adjustment by using the

offset adjustment screws. When you are satisfied

with the setting, retighten the clamping hex

bolts.

Figure 121. Carriage lock clamp.

Carriage

Lock

Clamp

Figures 118–122 show the location of the

adjustment screws for each gib on this machine.

Figure 120. Front saddle gib adjustment screw.

Gib Adjustment

Screw (1 of 2)

Figure 119. One of two rear saddle gib adjustment

screws.

Saddle Rear

Gib Adjustment

Screw (1 of 2)

Figure 122. Tailstock gib adjustment controls.

Gib Adjustment

Screw (1 of 2)

Clamping Hex

Bolt (1 of 2)

Offset Adjustment

Screw (1 of 2)